6

General Specifi cations

The complete line of 450XL compressors is comprised of six

models ranging from a nominal 88 kW cooling capacity 2-cylinder

machine all the way to the high end of the scale – a nominal 704

kW cooling capacity 16-cylinder model. In-between are the 4, 6,

8 and 12-cylinder mid-size units. All 450XL compressors run at a

maximum of 1200 RPM, and all are provided with built-in capacity

reduction steps for economical operation at reduced loads. V-belt

and direct-connected motor operation are also available through-

out the entire range of 450XL models.

We have tried to make every centimetre count in designing the

450XL to fi t into even the tightest space requirements. The 450XL

is a machine that provides displacement of 84,5 m3/h per cylinder,

giving you maximum capacity in a minimum amount of space.

There’s sure to be a 450XL model that’s a perfect match to your

refrigeration application.

Engineering Specifi cations

The compressor shall have double shaft seal, double tapered, roller

main shaft bearings.

Tri-Micro® oil fi lter and oil strainer that removes 95% of contami-

nants as small as 3 microns in size; dynamically and statically bal-

anced heavy duty crankshaft of ductile iron, also shot-peened on

6, 8, 12 and 16-cylinder models; spring safety heads; die-forged,

steel connecting rods with replaceable bearing halves; aluminum

type heat treated pistons with three compression rings and one oil

ring; piston operated suction valve lifters to unload the compressor

for starting and to provide capacity control. The piston and

connecting rods shall be assembled with a shrink-fi t wrist pin for

higher load carrying capabilities and superior wearing qualities.

The compressor shall come complete with structural steel base

and be equipped with the additional following standard equip-

ments: crankcase oil thermometer and heater; oil fi lter pressure

gauge with manual 3-way valve; oil failure switch; high and low

pressure cutout; capacity control switches and unloader solenoid

valves based on the number of steps of capacity reduction; water

or refrigerant cooled oil cooler; suction, discharge, and oil pressure

gauges complete with Stedy-Mounts® and shut-off valves; (water

or refrigerant) cooled cylinder covers following your need.

The parameters for the motors selection shall be:

- Required power (kW)

- Frequency (Hz) and Rotational speed (RPM)

- Voltage (Volt) and phasing

- Direct coupling or V-belt drive

The compressor minimal cooling capacity (kW) shall be defi ned for

given:

- Suction temperature (°C) or pressure (barg)

- Condensing temperature (°C) or pressure (barg)

Compressors are to be manufactured by Vilter Manufacturing

Corporation, Cudahy, Wisconsin, or equal as approved.

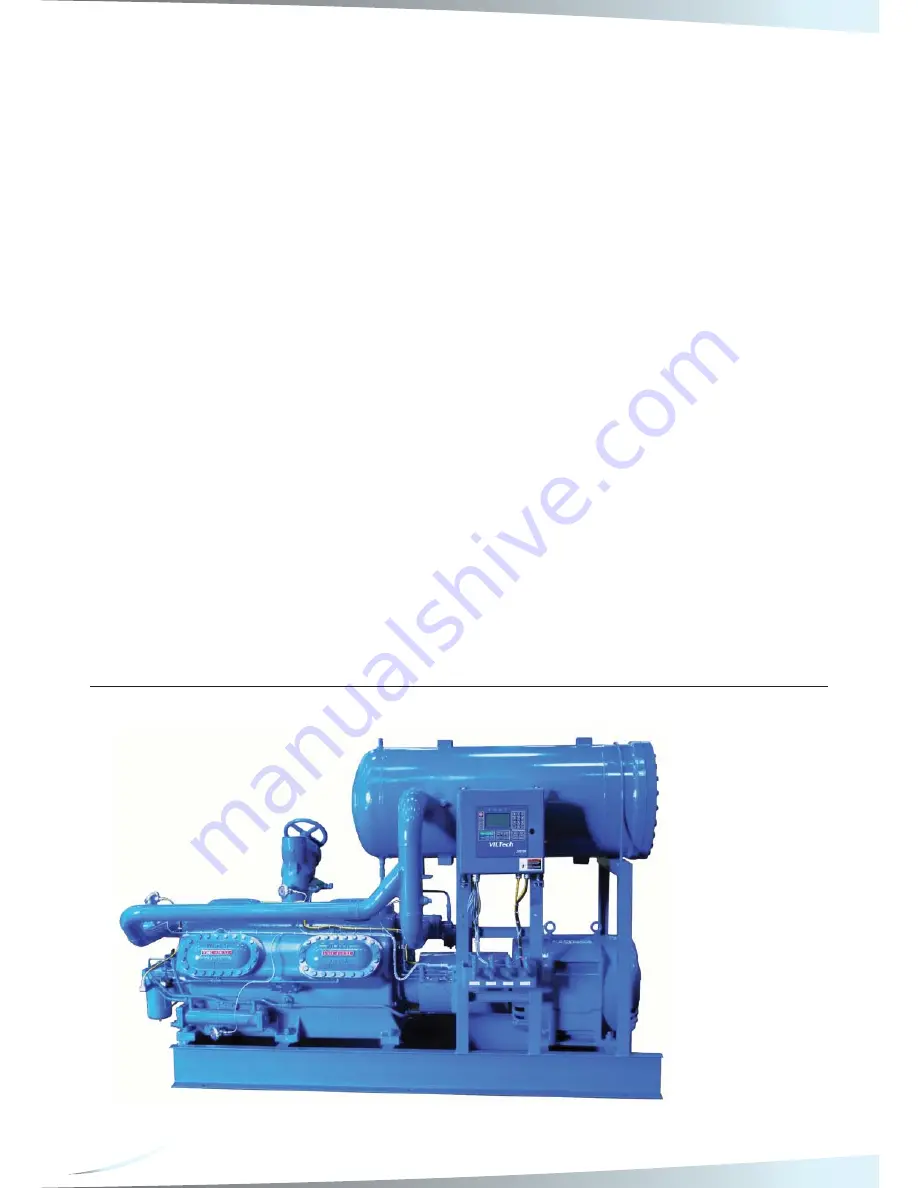

4512XL Direct Drive Recip Pak with

Superseparator and VILTech Micro-

Controller