B - 14

Appendix B

•

Vission 20/20 Application Procedures

Vission 20/20 • Operation and Service Manual • Emerson • 35391SC 2.7

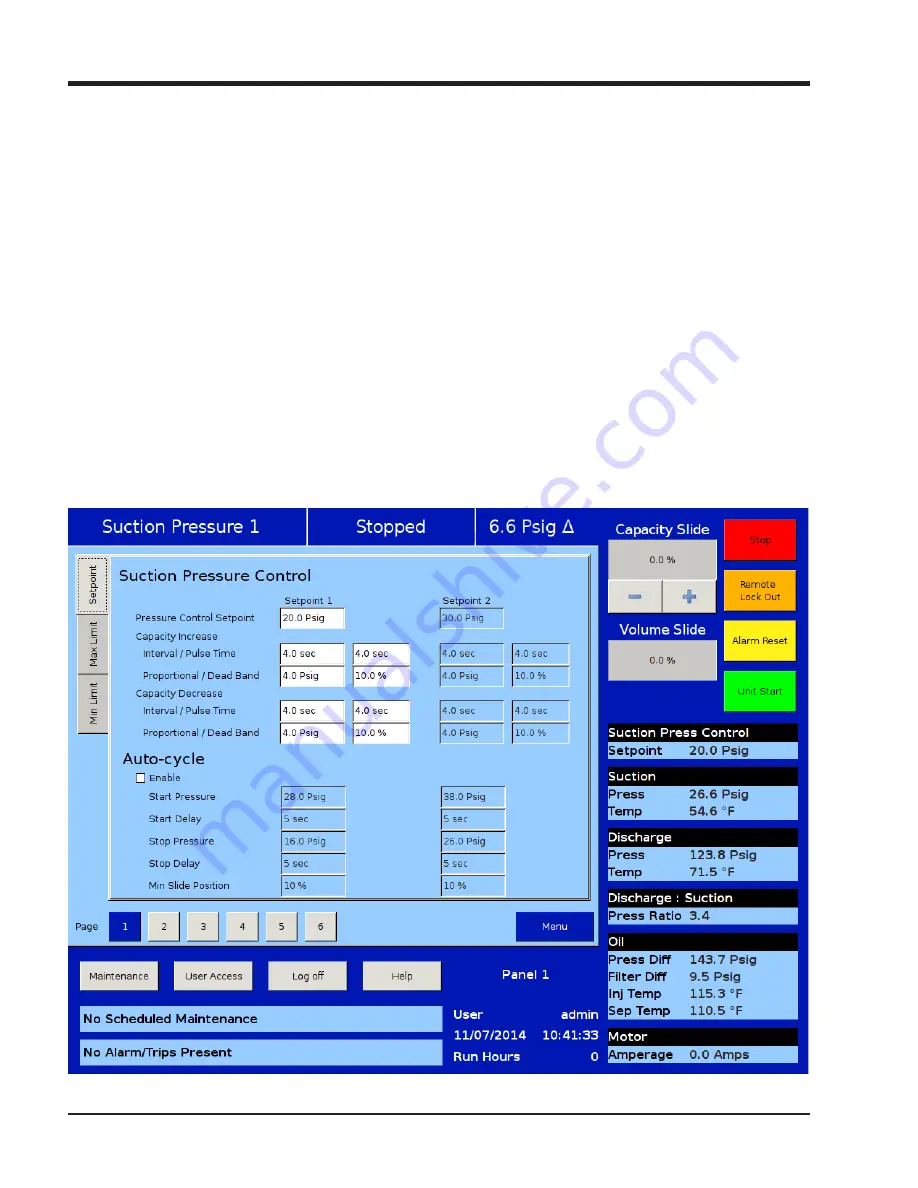

Vission 20/20 Compressor Sequencing Setup

SCOPE

Vission 20/20 programs – version 1.6.4550.1 and later.

OVERVIEW

Compressor sequencing in the Vission 20/20 panel is

carried out by utilizing the Ethernet communication

port using Modbus TCP protocol.

Compressor sequencing is accomplished by the master

compressor, monitoring its own control parameter (ei-

ther suction pressure, process temperature or discharge

pressure). As its control parameter changes value, it

will make decisions to start, stop, load and unload slave

compressors as needed, to maintain the control setpoint

which is defined in the master compressor sequencing

screen.

NOTE

The master compressor will ALWAYS be priority #1

compressor – and act as the trim compressor. So this

must be taken into account when deciding which

compressor is to act as the master compressor.

The following discussion assumes that the physical

Ethernet Network has been installed between all Vission

20/20 control panels.

Figure B-6. Master Compressor Loading, Unloading and Auto-cycle Setpoints Setup

Summary of Contents for Vilter Vission 20/20

Page 1: ...Vission 20 20TM Micro controller Operation and service manual Version 2 7 ...

Page 2: ......

Page 4: ......

Page 220: ...B 2 Blank Vission 20 20 Operation and Service Manual Emerson 35391SC 2 7 ...

Page 300: ...D 2 Blank Vission 20 20 Operation and Service Manual Emerson 35391SC 2 6 ...

Page 336: ......

Page 337: ......