6 – 17

Section 6

•

Compressor Control

Vission 20/20 • Operation and Service Manual • Emerson • 35391SC 2.7

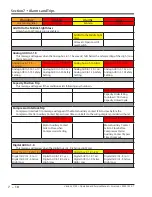

Figure 6-16. Compressor Control Screen - Liquid Injection & Dual Liquid Injection Control

value. By averaging the more stable oil manifold tem-

perature and discharge temperature, the control vari-

able stabilizes and the PID is more easily tuned.

Please note that as stated above, PID algorithms can be

difficult to tune and there is no one set of PID values that

will work. The work required for a compressor to meet

the requirement of its installation vary greatly and there-

fore the amount of heat transferred to the oil varies just

as greatly. We recommend the operator consult PID tun-

ing guides available from many different sources before

attempting to tune this PID.

Liquid Inj. Setpoint:

• Setpoint at which the liquid solenoid will activate if in

solenoid control or if the setting for the control vari-

able for the PID is in liquid motorized valve control.

Oil Sep. Temp. Override:

•

Defines the temperature the oil must reach before the

liquid injection solenoid is allowed to be activated.

P = Proportional (Gain):

• Used to adjust the positioning valve in direct propor-

tion to the difference between the control setpoint

and the discharge temperature (SP - DT = error). The

proportional term is a unitless quantity and is used

for coarse adjustment. This setpoint should be set to

the lowest value that gives adequate response to the

control system. Increasing the proportional setting

increases the control system’s sensitivity to small dis-

charge temperature fluctuations and the tendency to

hunt.

I = Integral (reset):

• This parameter integrates the error over time, to ac-

count for a small error that has persisted for a long

time. This quantity is used for fine adjustment. This

setpoint is used to smooth out discharge temperature

variations. This setpoint should be set high enough to

prevent hunting but not too high or it will cause con-

trol system overshoot.

D = Derivative (rate):

• This parameter accounts for how fast the error is

changing, positively or negatively.

Minimum Valve Open %:

• When enabled, this is the valve position used whenev-

er the control variable drops below Liquid inj. Setpoint

Summary of Contents for Vilter Vission 20/20

Page 1: ...Vission 20 20TM Micro controller Operation and service manual Version 2 7 ...

Page 2: ......

Page 4: ......

Page 220: ...B 2 Blank Vission 20 20 Operation and Service Manual Emerson 35391SC 2 7 ...

Page 300: ...D 2 Blank Vission 20 20 Operation and Service Manual Emerson 35391SC 2 6 ...

Page 336: ......

Page 337: ......