4 – 11

VSG/VSSG • Installation, Operation and Maintenance Manual •Vilter/Emerson • 35391STG

NOTICE

To purge the compressor unit using a dry gas (i.e.

methane), a purge line must be installed. If there is

not enough purge pressure, connect purge line to a

lower pressure line or to atmosphere.

The purge line,

associated valves and gauges are not provided from the

factory and must be installed by the customer.

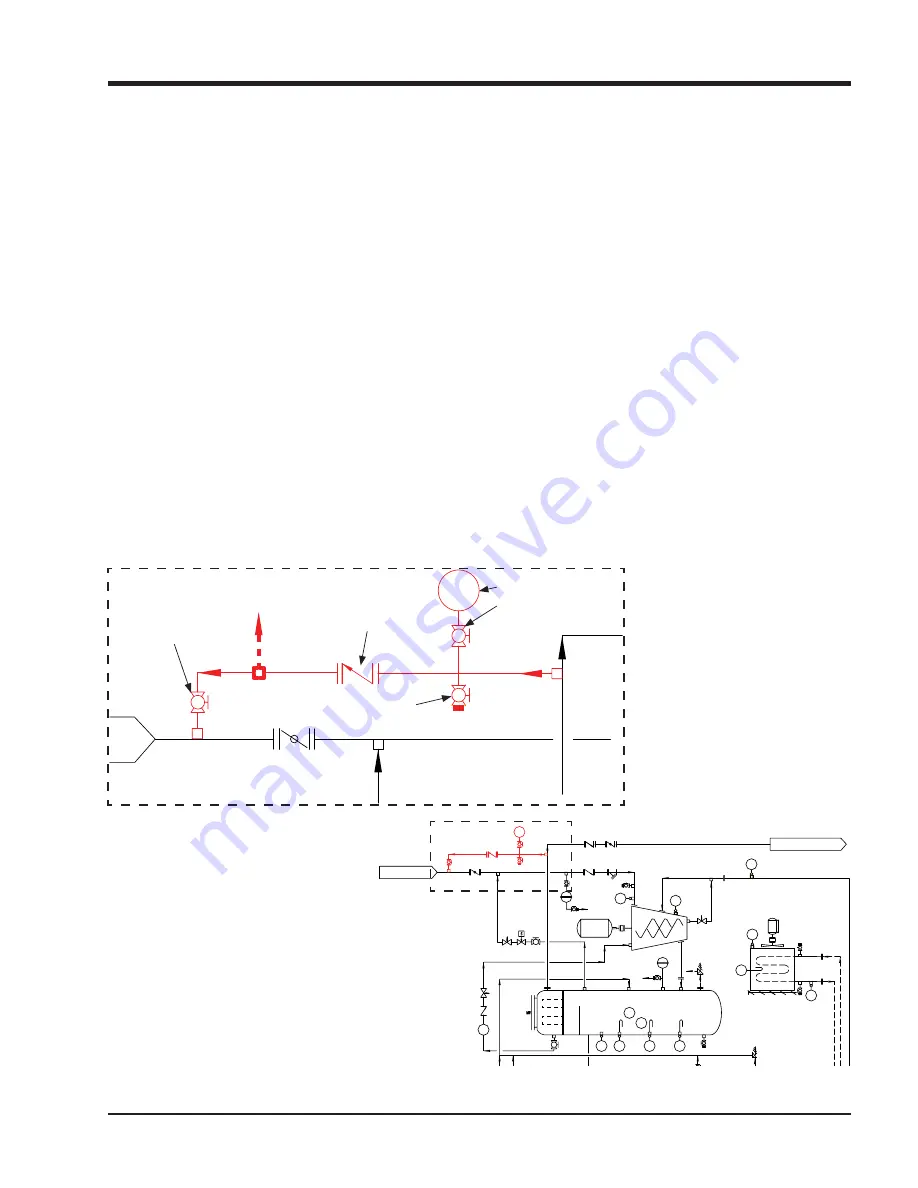

1. Refer to Figure 4-10 for recommended purge line

design.

2. Press “Stop” button to stop compressor unit, see

Figure 4-11.

3. Allow pressure in compressor unit to equalize to

suction pressure, see Figure 4-12.

4. Close suction and discharge shut-off valves to

isolate the compressor unit from house system.

Lockout/tagout valves.

5. Close any other valves that may feed gas or oil to

the compressor and oil separator.

Section 4 • Operation

Purging with Dry Gas

Purging is recommended if the compressor will be

inactive for 12 hours or more. For additional long

term storage information, refer to Long Term Storage

Recommendations in Section 3.

PREPARATION

WARNING

When working with LFG, NG or other dangerous

or

fl

ammable gases, ensure there are adequate

ventilation and vapor detectors. Refer to national

fi

re

and building codes. Failure to comply may result in

serious injury or death.

WARNING

When working with pressurized system, always wear

safety glasses and/or face shield. Failure to comply

may result in serious injury.

Figure 4-10. Customer Purge Line

PI

002

Shut-off Valve

Check Valve

Shut-off Valve

Pressure Indicator

Drain Valve

FG

001

TE

001

PT

001

BLEED

DRAIN

PT

002

BLEED

TE

004

QE

101

QE

102

QE

103

TE

005

1000W

1000W

1000W

LG

001

LG

002

OIL CHARGE

TE

002

PI

002

DRAIN

DRAIN

VENT

TE

003

QE

007

TE

007

OIL SEPARATOR

COMPRESSOR

MOTOR

REMOTE

OIL COOLER

COALESCING OIL

RETURN LINE

PURGE LINE

PRESSURE

EQUALIZING LINE

SUCTION INLET

DISCHARGE OUTLET

To Lower Pressure Line or

Atmosphere. See NOTICE.