5 – 28

VSG/VSSG • Installation, Operation and Maintenance Manual •Vilter/Emerson • 35391STG

Section 5 • Maintenance/Service

bearing end of the gate rotor support towards the

suction end of the compressor. The compressor

input shaft may have to be rotated to facilitate the

installation of the gate rotor support.

11. Install the roller bearing housing with a new O-ring.

Tighten the bolts to the recommended torque

value.

12. Install the spindle with shims and O-ring, tighten

bolts, see Appendix A. Measure the clearance be-

tween the shelf and blade.

13. Check the clearance between the entire gate ro-

tor blade and the shelf, rotate the gate rotor to

fi

nd the tightest spot. It should be between 0.003-

0.004“ (0.076-0.102 mm). Make adjustments, if

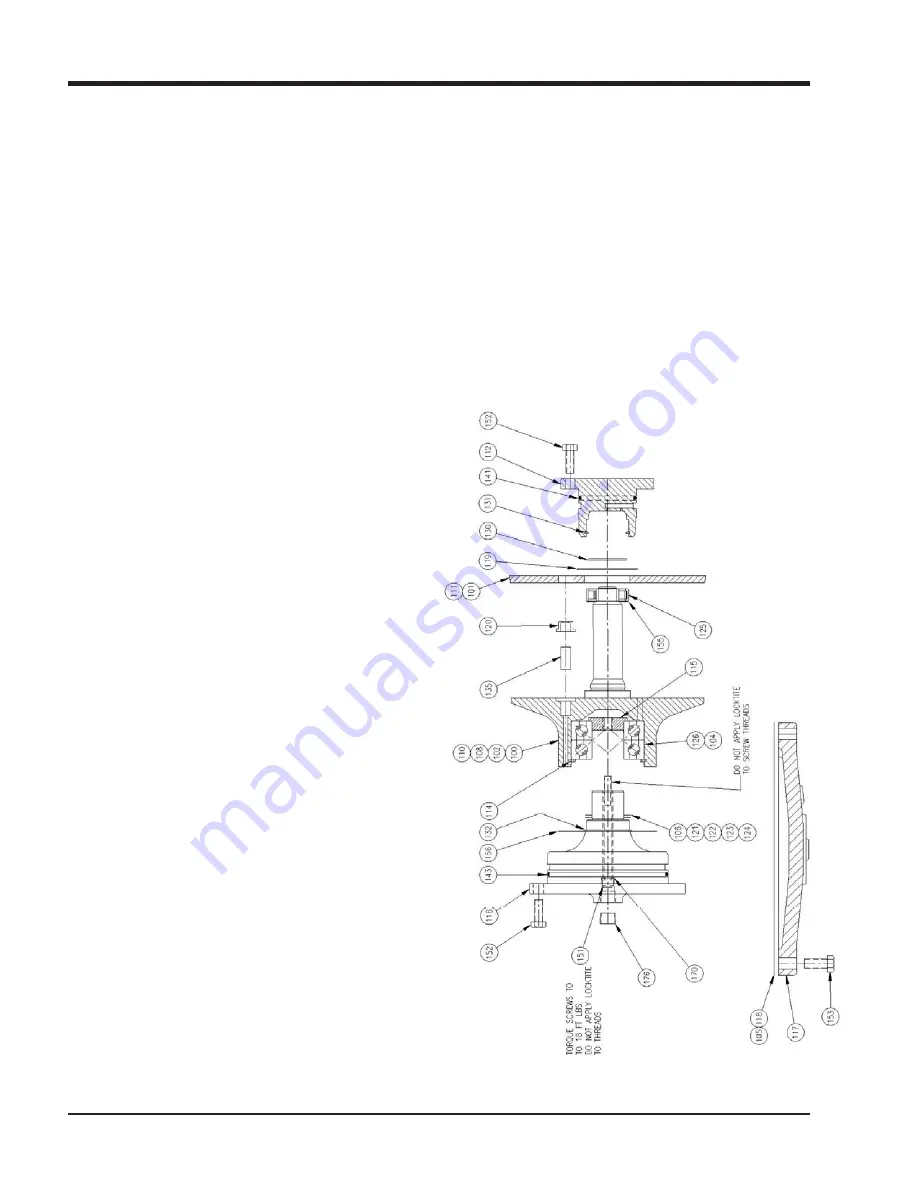

Figure 5-26. Gate Rotor Assembly Breakdown

Gate Rotor Assembly Replacement

(VSG 301-701 Compressors ONLY)

REMOVAL

The removal of the gate rotor assembly for the VSG 301-

701 compressors is similar for the VSG 901- 2101 com-

pressors except that the inner races are secured to the

stationary bearing spindle.

1. Remove center member, see appropriate Drive

Coupling Replacement procedure.

2. Remove the upper bolt from the side cover and in-

stall a guide stud in the hole.

3. Remove remaining bolts and side cover. There will

be some oil drainage when the cover is removed.

4. The side cover that contains the suction strainer

should have the suction line properly supported

before the bolts securing the line to the cover can

be removed. After the line is removed, the cover

can be removed per paragraph B.

5. Turn the main rotor so the driving edge of the

groove is between the top of the shelf or slightly

below the back of the gate rotor support. At this

point install the gate rotor stabilizing tool.

6. Remove plug on the thrust bearing housing. Loosen

the socket head cap screw that is located under-

neath the plug. This secures the inner races of the

thrust bearings to the spindle.

7. Remove bolts that hold the thrust bearing housing

to the compressor. Insert two of the bolts into the

threaded jacking holes to assist in removing the

bearing housing from the compressor. When the

housing is removed, there will be shims between

the spindle and thrust bearings. These control the

clearance between the shelf and gate rotor blades.

These must be kept with their respective parts for

that side of the compressor.

8. Remove the bolts from the roller bearing housing.

After the bolts have been removed, the housing

can be removed from the compressor.

9. To remove the gate rotor support, carefully move

the support opposite the direction of rotation and

tilt the roller bearing end towards the suction end

of the compressor. The compressor input shaft may

have to be turned to facilitate the removal of the

gate rotor support. On dual gate versions, repeat

the procedure for the remaining gate rotor support

assembly.

INSTALLATION

10. Install the gate rotor support. Carefully tilt the roller