5 – 32

VSG/VSSG • Installation, Operation and Maintenance Manual •Vilter/Emerson • 35391STG

Section 5 • Maintenance/Service

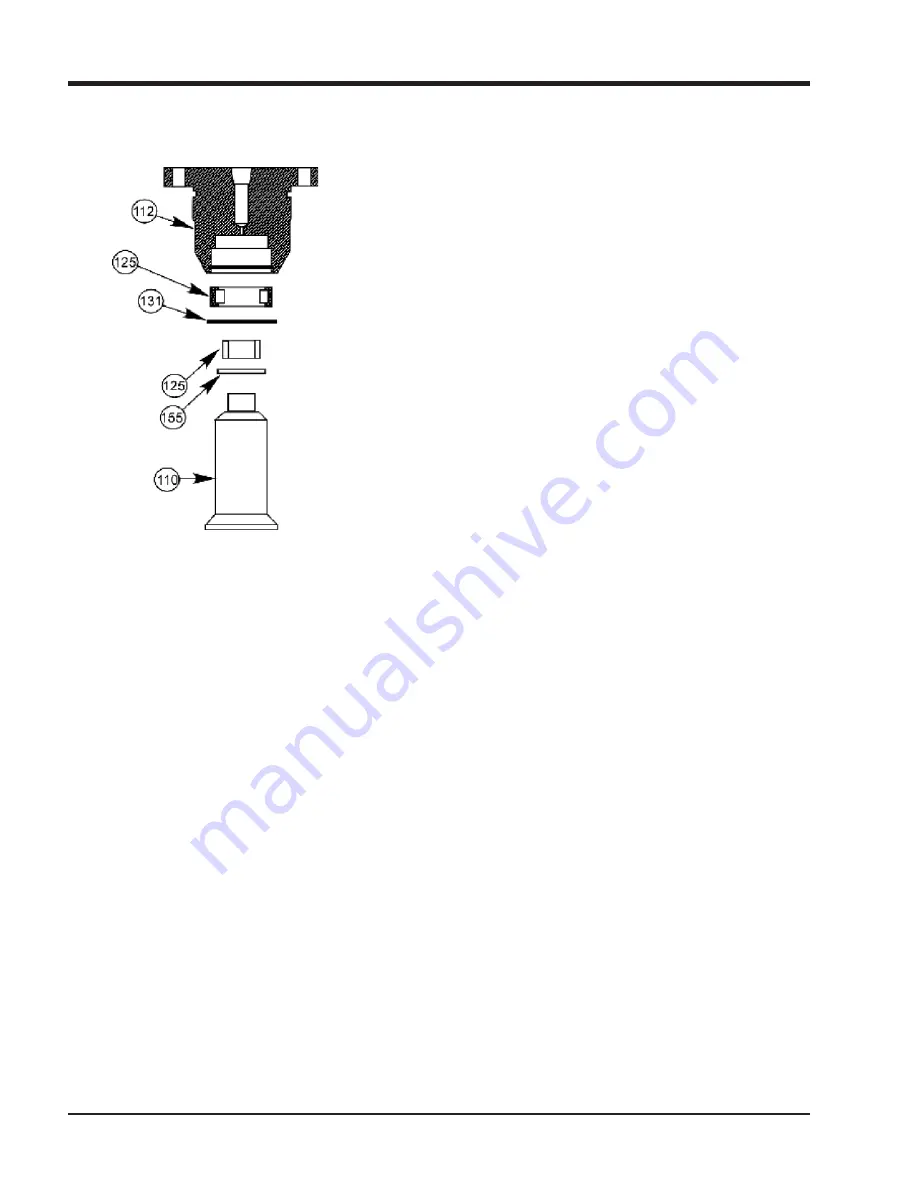

The bevel on the snap ring must face away from the

roller bearing.

Figure 5-33. Roller Bearing Assembly

Slide Valve Actuator Assembly

Replacement

To replace slide valve actuator assembly, proceed with

the following steps:

REMOVAL

WARNING

At shutdown, open any other valves that may trap

liquids to prevent serious injury and/or damage to

equipment.

WARNING

Follow local lockout/tagout procedure. Failure to

comply may result in serious injury, death and/or

damage to equipment.

NOTE

This procedure is applicable to both capacity and

volume slide valve actuator assemblies.

1. Shut down the compressor unit, refer to Stopping/

Restarting procedure in Section 4.

2. Turn disconnect switches to the OFF position for

the compressor unit and oil pump motor starter, if

equipped.

3. Allow compressor, motor and surrounding compo-

nents to cool prior to servicing.

4. Disconnect connectors from actuator.

NOTE

Note orientation of components to aid in installation.

5. Remove screws and lock washers securing actuator

assembly to actuator mount.

6. Remove actuator assembly from actuator mount.

INSTALLATION

CAUTION

When installing the slide valve actuator assembly,

loosen locking collar down the shaft. Do not use a

screwdriver to pry locking collar into position.

7. Position actuator assembly on mount as noted in

removal.

8. Install lock washers and screws to secure actuator

assembly to actuator mount.

9. Tighten screws, see Appendix A.

CAUTION

If installing new actuator, do not connect connectors

of power cable or position transmitter cable to new

actuator once installed. Connecting connectors to

new actuator will occur during calibration procedure.

Failure to comply may result in damage to equipment.

10. Leave connectors disconnected to actuator

assembly.

11. Calibrate actuator assembly, see Slide Valve

Calibration procedure in Section 4.