5 – 38

Section 5 • Maintenance/Service

VSS/VSR/VSM/VSH/VSSH Compressor • Installation, Operation and Service Manual • Emerson • 35391S

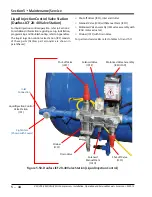

Prior to Shaft Seal Installation

WARNING

Follow local lock-out/tag-out procedure. Compressors

must be depressurized before attempting to do any

work on them. Failure to comply may result in serious

injury, death and/or damage to equipment.

NOTE

Care must be taken when handling the cup assembly

and mating ring when installing. See Figure 5-40 for

Handling Seal Face with Care.

Suggestion

A spray bottle filled with clean compressor oil may be

used to lubricate the faces of the seals without touching

the seal.

Follow these steps to verify the integrity of a shaft seal:

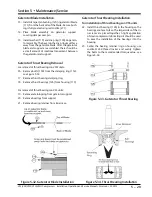

1. Check lead chamfer and outer diameter of shaft for

deep scratches that may potentially damage the

O-ring on the inner diameter of the shaft seal, see

Figure 5-45:

Figure 5-46. Shaft Seal Housing

Figure 5-45. Shaft with Pin

Drive Pin on Shaft

Lead Chamfer on Outer

Diameter of Shaft

Shoulder to

Which Seal Will

Bottom on

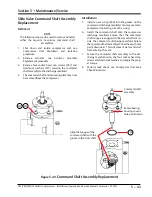

Figure 5-47. The Alignment of Compressor

Shaft and Mating Ring

Shoulder on

Compressor Shaft

Align slot in mating

ring (219C) with drive

pin on compressor

shaft

219C

O-ring

2. Check lead chamfer and inner diameter of shaft

seal housing for burrs and/or deep scratches that

may potentially damage the O-ring on the outer

diameter of the shaft seal, see Figure 5-46.

3. Clean compressor shaft and shaft seal cavity in

compressor housing.

4. Apply clean compressor lubricating oil to the

compressor shaft in mating ring seating area, see

Figure 5-47.

Notch in shaft

seal for alignment

with drive pin on

the shaft

Shaft Seal See

Table 5-9

Anti-rotation

pin

Back wall of housing to

which shaft seal/shim

will bottom on

Lead chamfer on

inner diameter of

housing