1592019030 XEV02D GB r1.2 04.06.2015

XEV02D

3/4

dCt

Cooling time for DG compressor after DLT alarm:

0 to 255 min

dLn

Number of DLT alarms in dLi hours before blocking compressor:

0 to 15,

0=function disabled.

dLi

Time interval (in hours) in which to check dLn number of DLT alarms:

0 to 24

hours; 0=function disabled.

CEd

Maximum compressor capacity (in percentage) in case of probe error:

0 to 100%

Cdd

Maximum compressor capacity (in percentage) in case of DLT alarm and for time

dLd:

0 to 100%

CEi

Maximum compressor capacity (in percentage) in case of regulation input error:

0 to 100%

dEr

Alarm delay in case of regulation input/probes reading error:

0 to 999 sec

OTHER

A2F

ALARM key timed function configuration (push button timed, 3 sec): nu

=not used;

onF=ON-OFF function.

Adr

Serial address:

1 to 247

bAU

Baudrate for serial communication:

9.6

=9600 baud;

19.2

=19200 buad.

dP1

Analogue output value (read only)

dP2

Probe P2 value (read only)

d1S

Digital input status display (isolated contact) (read only)

d2S

Digital input status display (not isolated contact) (read only)

rEL

Release Firmware (read only)

Ptb

Parameters table code (read only)

Pr2

Protected parameters menu access

8. DIGITAL INPUTS

The device is provided with two digital inputs. One is free of voltage and the other is at high voltage

and both can be configured as cooling call. In this way the cooling signal can come from instruments

with direct load outputs or via instruments with output without voltage.

9. ELECTRICAL CONNECTIONS

The instrument is provided with pluggable screw terminal block to connect cables with a cross section

up to 2.5 mm

2

. Heat-resistant cables have to be used. Before connecting cables make sure the power

supply complies with the instrument’s requirements. Separate the probe cables from the power supply

cables, from the outputs and the power connections. Do not exceed the maximum current allowed on

each relay, in case of heavier loads use a suitable external relay.

10. RS485 SERIAL LINE

All models can be connected to a MODBUS network by using the 2-wire RS485 port. The XWEB

related library and the MODBUS protocol can be issued on customer request from DIXELL.

11. USE THE HOT-KEY

11.1

PROGRAM A HOT-KEY FROM THE INSTRUMENT (UPLOAD)

1)

Program one controller with the front keypad.

2)

When the controller is ON, insert the

HOT-KEY

and push

UP

button; the “

uPL

”

message

appears followed a by flashing “

End

”

.

3)

Push

SET

button and the “

End

” will stop flashing.

4)

Turn OFF the instrument, remove the

HOT-KEY

and

then turn it ON again.

NOTE

: the “

Err

” message is displayed in case of any failed programming operation. In this case, push

again

UP

button if you want to restart the upload again or remove the

HOT-KEY

to abort the

operation.

11.2

PROGRAM AN INSTRUMENT USING A HOT KEY (DOWNLOAD)

1)

Turn OFF the instrument.

2)

Insert a pre-programmed

HOT-KEY

into the 5-PIN connector and then turn the Controller ON.

3)

Automatically the parameter list present into the

HOT-KEY

will be downloaded into the

Controller memory. The “

doL

” message will blink during this operation, followed a by a flashing

“

End

” label.

4)

After 10 seconds the instrument will restart working with the new parameters.

5)

Remove the

HOT-KEY

.

NOTE:

the “

Err

” message is displayed in case of any failed programming operation. In this case, push

again

UP

button if you want to restart the upload again or remove the

HOT-KEY

to abort the

operation.

12. ALARM MENU

Press the

ALARM

button to access the alarms database menu if. This menu contains a

LIFO

format

log of the last 10 registered alarms. The menu structure is as follows:

-

the alarm number in AL0...AL9 format (0 is the oldest alarm, 9 is the last received alarm) is

displayed once accessed;

-

it is possible to scroll the registered alarms by using the

UP

and

DOWN

buttons;

-

it is possible to display the following alarm information (in sequence) by using the

SET

button:

the alarm code (3 digit label according to that described) and alarm duration in

h.mm

(1 minutes

resolution, max stored value is 19h59min).

12.1

ALARMS ARCHIVE ERASING:

All saved alarms can be deleted by keeping the

ALARM+SET

key pressed for 5 sec when into

ALARM MENU. The display will show the “rSt” label (flashing) for 3 sec and then the default display

visualization will be restored (

Lod

variable).

NOTE:

-

All saved alarms can be also deleted via special MODBUS command.

13. DISPLAY MESSAGES

Mess.

Cause

Outputs

A02

Digital input configured as

EAL

function is active Unchanged

A03

Missing regulating signal (analogue input drops

below

dSL

value)

Unchanged

E01

DLT alarm active

Output disabled, alarm output activated

E02

A

dLn

number of DLT alarms in time interval (in

hours)

dLi

was detected.

Output disabled, alarm output activated

E03

Digital input configured as

bAL

function is active Output disabled, alarm output activated

E05

Missing regulating signal (analogue input drops

below

dSL

value more than

dEr

time)

Output disabled, alarm output activated

E07

Low temperature alarm active

Output disabled, alarm output activated

P1

Analogue input error

Output disabled, alarm output activated

P2

Temperature transducer in error

Output disabled, alarm output activated

13.1

ALARM RECOVERY

Probe alarms “

P1

” and “

P2

” start

dEr

seconds after the fault in the read value; they automatically stop

few seconds after the probe restarts normal operation. Check connections before replacing the probe.

Alarms

E01, E03

and

E05

automatically stop as soon as their root causes disappear.

Alarm

E02

and

E07

require a manual re-start by switchinf OFF and ON the device or by sending a

MODBUS command.

14. TECHNICAL DATA

Housing:

self extinguishing ABS

Case:

4 DIN modules 70x135mm with male and female connectors; depth 60mm

Mounting:

DIN RAIL mounted in an omega (3) din rail

Protection:

IP20

Connections:

screw terminal block

2.5 mm

2

wiring

Power supply:

24Vac/dc ±10%; 110VAC ±10% or 230VAC ±10%

Power absorption: depending on connected valve

20VA max

Display:

3.5 digits with icons, red LEDs, height 14.2 mm

Temperature input:

1 temperature probe

PT1000 probe:

-55 to 200°C (-67 to 392°F)

NTC10k probe:

-40 to 110°C (-40 to 230°F)

NTC86k probe:

-40 to 180°C (-40 to 356°F)

Analogue control input:

0 to 10Vdc

4 to 20mA

Digital inputs:

1

free of voltage

1 isolated (voltage depending on the power supply)

Digital outputs:

1 relay output, 8(3)A, 250VAC

1 open collector output, max current 40mA

TRIAC output:

max 30W

Data storage:

on the non-volatile memory (EEPROM)

Kind of action:

1B

Pollution degree:

normal

Software Class:

A

Operating temperature:

0 to 55°C (32 to 131°F)

Storage temperature:

-25 to 60°C (-13 to 140°F)

Relative humidity:

20 to 85% (no condensing)

Resolution:

0.1°C or 1°F

Precision a 25°C (77°F):

±0.7°C ±1digit

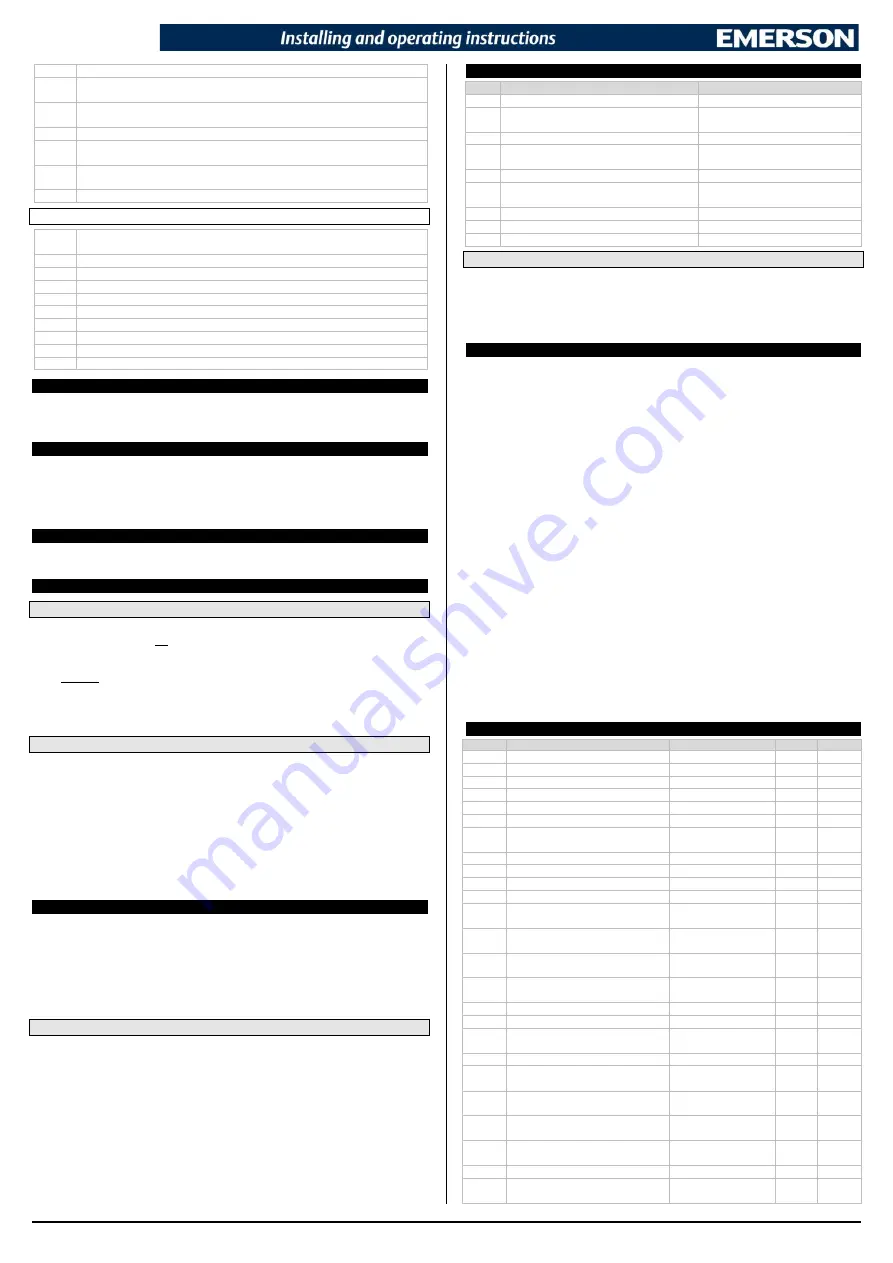

15. STANDARD VALUES

Label

Description

Range

Default

Level

oA1

Digital output 1 configuration

nu; ALr; CPR; dmd

CPr

Pr1

oA2

Digital output 2 (o.c.) configuration

nu, ALr

nu

Pr2

oP1

Digital output 1 polarity

oP; CL

oP

Pr1

oP2

Digital output 2 (o.c.) polarity

oP; CL

oP

Pr2

tbA

Alarm output deactivation

no; Yes

no

Pr2

bEn

Buzzer (software) management

on; oFF

on

Pr2

P2C

Temperature probe configuration (it

depends on the hardware)

nu; Pt1; ntC; n86

(*)

Pr1

o2

Probe P2 calibration

-12 to 12°C; -21 to 21°F

0.0

Pr1

PA4

Analogue input at 4mA or 0V

0 to 100%

0.0

Pr2

P20

Analogue input at 20mA or 10V

0 to 100%

100

Pr2

Lod

Default displayed variable

PEr; Ain; P2

PEr

Pr1

CF

Units

of

measurement

for

temperature

°C; °F

°C

Pr1

rES

Temperature resolution (valid only if

CF=°C)

in; dE

dE

Pr1

i1F

Digital input 1 configuration (voltage

free contact)

nP; EAL; bAL; onF

EAL

Pr1

i2F

Digital input 2 configuration (high

voltage input)

nP; EAL; bAL; onF

onF

Pr1

i1P

Digital input 1 polarity

oP; CL

CL

Pr1

i2P

Digital input 2 polarity

oP; CL

CL

Pr1

Sut

Start up time: valve activation time

before starting the regulation

0.0 to 25.5 sec

3.0

Pr1

tdG

Modulation time interval

6 to 40 sec

20

Pr1

ALL

Low temperature alarm

-30 to 200°C;

-22 to 392°F

-30

Pr2

dLL

Low temperature alarm activation

delay

0 to 999 sec

180

Pr2

dLt

Discharge line temperature

-30 to 200°C;

-22 to 392°F

145

Pr1

dth

Differential

0 to 99.9°C;

0 to 999°F

10

Pr1

dLd

DLT alarm activation delay

0 to 999 sec

60

Pr1

dCt

Cooling time for DG compressor

after DLT alarm

0 to 255 min

10

Pr1