460D3

900

150

900

515D3

1500

150

900

YARWAY

SERIES 460D3 AND 515D3 INTEGRAL STRAINER HIGH PRESSURE DISC TRAPS

INSTRUCTION, OPERATION AND MAINTENANCE MANUAL

RATING

Disc traps operate from 150 psig to 1500 psig.

Operation at lower pressures may result in

reduced air handling properties, and low cycle

rates.

The maximum allowable back pressure outlet

is 80% of pressure at trap inlet, based on

absolute pressures.

Emerson.com/FinalControl

© 2017 Emerson. All rights reserved.

VCIOM-09544-EN 19/05

Before installation these instructions must be fully read and understood

SERIES NUMBERS

To determine the size, series number, and

operating conditions rating, refer to the

nameplate on the trap body.

Suffix letter identification

SW

Socket weld ends

FL

Flanged ends (special option)

D3

Disc trap

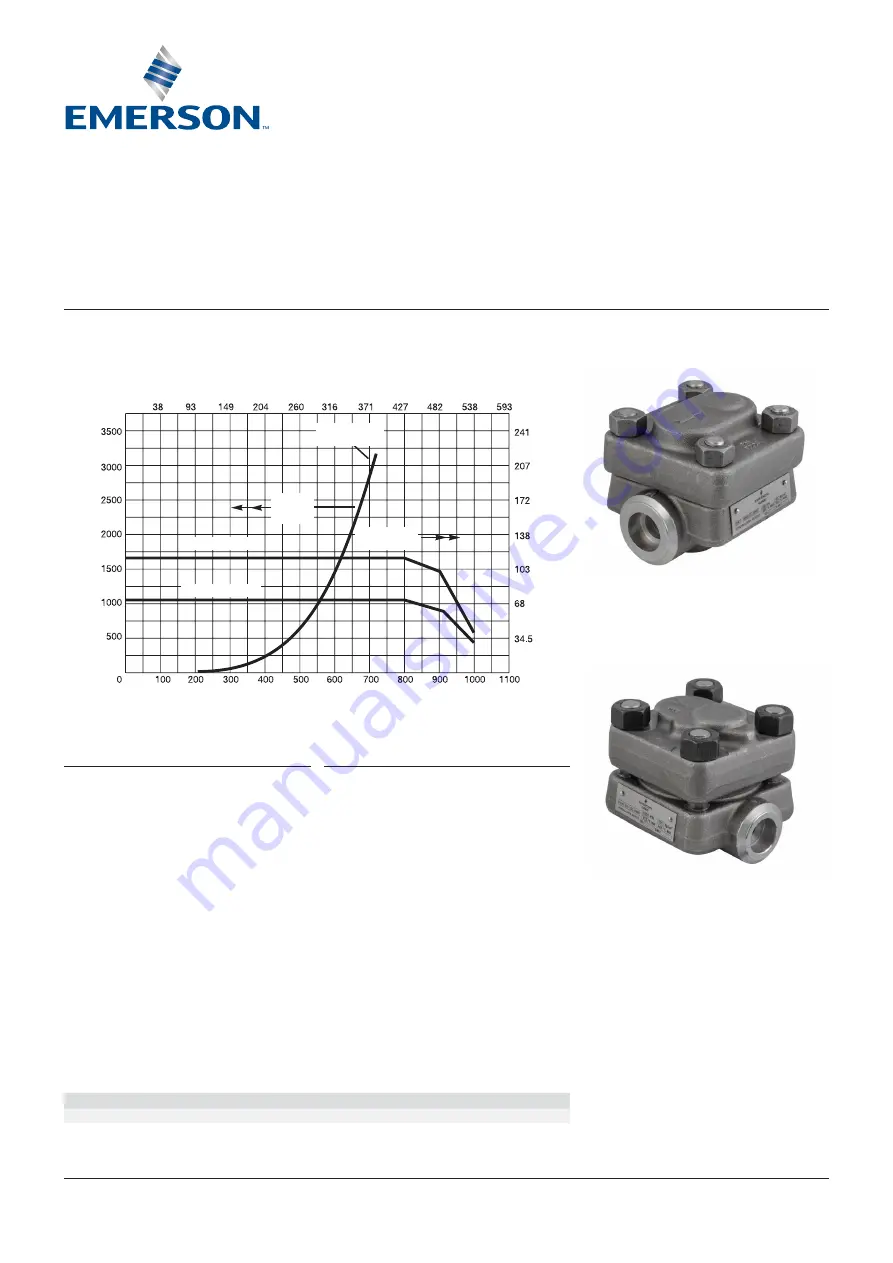

SHELL PRESSURE/TEMPERATURE RATINGS

Trap operating conditions

Maximum operating pressure (psig)

Maximum operating temp. (°F)

DESIGN PRESSURE/TEMPERATURE RATINGS

SATURATION

CURVE

SERIES 515D3

SERIES 460D3

MAX. PRESSURE,

psi

MAX. PRESSURE,

bar

MAX. TEMPERATURE (F)

MAX. TEMPERATURE (C)

ALL

LIQUID

PHASE

ALL

SUPERHEAT

SERIES 460D3

SERIES 515D3