3

YARWAY

SERIES 460D3 AND 515D3 INTEGRAL STRAINER HIGH PRESSURE DISC TRAPS

INSTRUCTION, OPERATION AND MAINTENANCE MANUAL

MAINTENANCE

Check bonnet nut torque after 48 hours

of operation.

1. For the best trap operation and maximum

service life, strainer screen should be

cleaned frequently. This can best be done by

using a blowdown valve connected to blow-

off connection.

2. Periodically remove the bonnet and clean

and inspect the screen. This should be done

at least once a year and more frequently

if the trap is not fitted with a strainer

blowdown valve.

3. When cleaning the strainer it is

recommended that the trap be inspected

and working parts cleaned if necessary. In

the event of condensate drainage problems,

check before opening the trap whether

the trouble is due to a clogged line, valve

broken or in wrong position, or dirty strainer

requiring blowdown.

4. More frequent checks for proper trap

operation can be quickly made by one of the

following methods:

a. Observe the discharge from the trap

through the test connection-first closing

the downstream stop valve.

b. Hold screwdriver or metal rod against

base of cap. Listen for characteristic

clicking sound of valve as it opens and

closes.

c. Check temperature of the cleaned pipe

surface up and downstream of trap.

Use a touch pyrometer or temperature

sensitive crayon.

If trap is remaining open continuously or not

operating at all:

• Strainer screen may be damaged or dirty

• Parts may be worn from service

• Dirt and scale may be lodged in internals

Disassemble and inspect the trap.

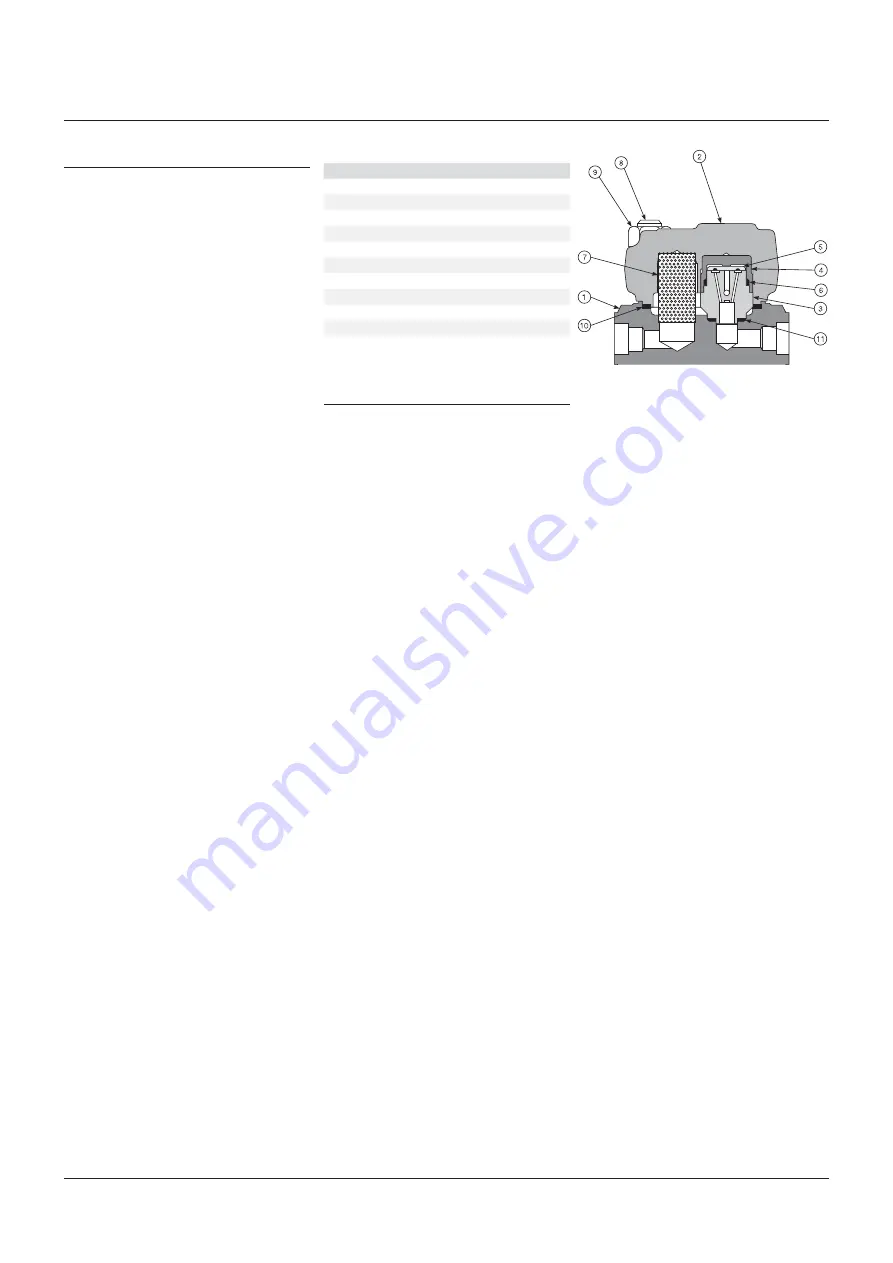

PARTS LIST

Item

Quantity

Description

1

1

Body

2

1

Bonnet

3*

1

Seat

4*

1

Cap, seat

5*

1

Disc

6*

1

Gasket, capsule

7*

1

Screen

8

4

Stud

9

4

Nut

10*

1

Gasket, bonnet

11*

1

Gasket, seat

* Renewal kit

DISASSEMBLY

1. Remove bonnet.

2. Remove seat capsule from bonnet. The

capsule is a clearance fit in the bonnet bore.

It may be necessary to insert a small rod in

the seat inlet port and extract the capsule

with a turning, pulling motion.

3. Inspect and clean all parts. If satisfactory,

reassemble trap. See page 4 for repair kit

installation and assembly.