4

YARWAY

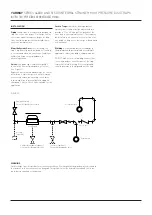

SERIES 460D3 AND 515D3 INTEGRAL STRAINER HIGH PRESSURE DISC TRAPS

INSTRUCTION, OPERATION AND MAINTENANCE MANUAL

SERVICING

After disassembly, clean internal parts

with a cloth and non-corrosive solvent.

Replace the capsule, screen and gaskets for

best performance.

The capsule gasket is not furnished with the

repair kit and should be ordered separately.

If required, the trap capsule may be

disassembled by holding the cap in a vice with

soft copper or aluminum jaws, inserting a

short rod in the seat inlet port, and the seat

extracted with a twisting, pulling motion.

The sealing gasket will remain in the cap.

Inspect the disc and seat for dirt and wear.

Remove adhered dirt using a soft cloth and

non-corrosive solvent. If the seat and disc are

serviceable and capsule reassembly is desired,

remove the capsule gasket from the cap;

use care to avoid damage to the cap sealing

surface. Verify the gasket metal end caps have

been removed from the cap; reassemble the

capsule using a new gasket. The capsule can

then be placed in the trap.

An alternate method of capsule assembly is to

partially compress the gasket before placing

the capsule in the trap. The gasket may be

compressed by placing the capsule in an arbor

press, protecting the gasket and cap surfaces,

and applying sufficient load to reduce the space

between the cap and seat approximately 50%.

It is not necessary for the cap to contact the

seat. The space between seat an cap contact

will increase when load is removed, due to

gasket springback. The seated gasket holds the

parts together, and creates a single part that is

easily handled and simplifies trap assembly.

SPARE PARTS

To cover a one year service period, it is

recommended that spare parts be stocked as

follow:

Renewal kit -

one (1) for every four (4) traps.

Minimum number of kits one (1) and sufficient

gaskets for trap inspection.

Other replacement parts

Conversion kit -

consisting of (1) bonnet,

(1) capsule assembly, (1) screen, (1) seat to

body gasket, (1) bonnet gasket.

Steam trap figure no.

Conversion kit part no.

460 A, B, C to 460D3

972401-04

515 A, B, C to 515D3

972376-03

Renewal kit -

consisting of (1) capsule

assembly, (1) screen, (1) seat to body gasket, (1)

bonnet gasket.

Steam trap figure no.

Renewal kit part no.

360D3

972401-02

515D3

Gaskets, 460D3 and 515D3

Bonnet gasket

965924-02

Seat gasket

965924-01

Capsule gasket

972400

REASSEMBLY

1. Clean sealing surfaces and all internal parts.

2. Clean studs and nuts, lubricate studs and

nut faces with high temperature lubricant.

3. Push screen into body recess. Place capsule

in bonnet. With bonnet and seat gaskets in

place, lower bonnet over studs.

4. Replace bonnet nuts, hand tighten, then

tighten alternately to the torque listed.

BONNET NUT TORQUE VALUES

Figure no.

ft·lbs

(Nm)

460D3

65 - 70

(88 - 95)

515D3

110 - 130

(149 - 176)