5

YARWAY

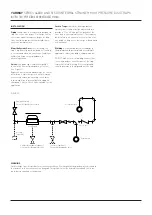

SERIES 460D3 AND 515D3 INTEGRAL STRAINER HIGH PRESSURE DISC TRAPS

INSTRUCTION, OPERATION AND MAINTENANCE MANUAL

NOTE

Any malfunction of this product must be reported to the service department.

Repare made to the product by unauthorized personnel will void the warranty.

Right to know laws and OSHA standard 29CFR (1910.1200)

Material Safety Data Sheets on the following Yarway products:

Valves, Steam traps and Strainers

The OSHA Hazard Communication Standard 29CFR 1910.1200, states that the standard does not

apply to “articles.” The standard defines an article as:

“A manufactured item formed to a specific shape or design for a particular use which does not

release or otherwise expose an employee to a hazardous chemical under normal conditions of use.”

The above named products fall within the definition of an “article”, no Material Safety Data Sheets

are available or are required. Our product is manufactured as an “end product.”

If the product is a weld end the following applies.

WARNING

Materials used in manufacture of Yarway products are considered in a stable condition when shipped.

However, under certain conditions purchasers could create potential hazardous conditions by their

future operations.

CAUTION

Welding, cutting, burning, machining or grinding of this product can generate toxic dust and fumes of

potentially hazardous ingredients. The dust or fumes can cause irritation of the respiratory tract, nose,

throat, skin and eyes. It may cause temporary or permanent respiratory disease in a small percentage

of exposed individuals. Use moderate ventilation when grinding or welding. Avoid breathing dust, fumes

or mist. Avoid prolonged skin contact with dust or mist. Maintain dust levels below OSHA and ACGIH

levels. Use protective devices. Wash hands thoroughly after contact with dust before eating or smoking.

Neither Emerson, Emerson Automation Solutions, nor any of their affiliated entities assumes responsibility for the selection, use or maintenance of any product.

Responsibility for proper selection, use, and maintenance of any product remains solely with the purchaser and end user.

Yarway is a mark owned by one of the companies in the Emerson Automation Solutions business unit of Emerson Electric Co. Emerson Automation Solutions, Emerson and

the Emerson logo are trademarks and service marks of Emerson Electric Co. All other marks are the property of their respective owners.

The contents of this publication are presented for informational purposes only, and while every effort has been made to ensure their accuracy, they are not to be construed

as warranties or guarantees, express or implied, regarding the products or services described herein or their use or applicability. All sales are governed by our terms and

conditions, which are available upon request. We reserve the right to modify or improve the designs or specifications of such products at any time without notice.

Emerson.com/FinalControl