8

25

•

21

•

23

•

27

•

26

12

9

13 14

22

•

•

19

24

•

•

•

10

•

•

11

6

•

20

•

1

•

•

•

18

•

2

4

•

7

•

5

•

17

•

•

3

•

15

16

•

8

YArwAY

TemplowHT desuperHeaTer

InstallatIon and MaIntenance InstructIons

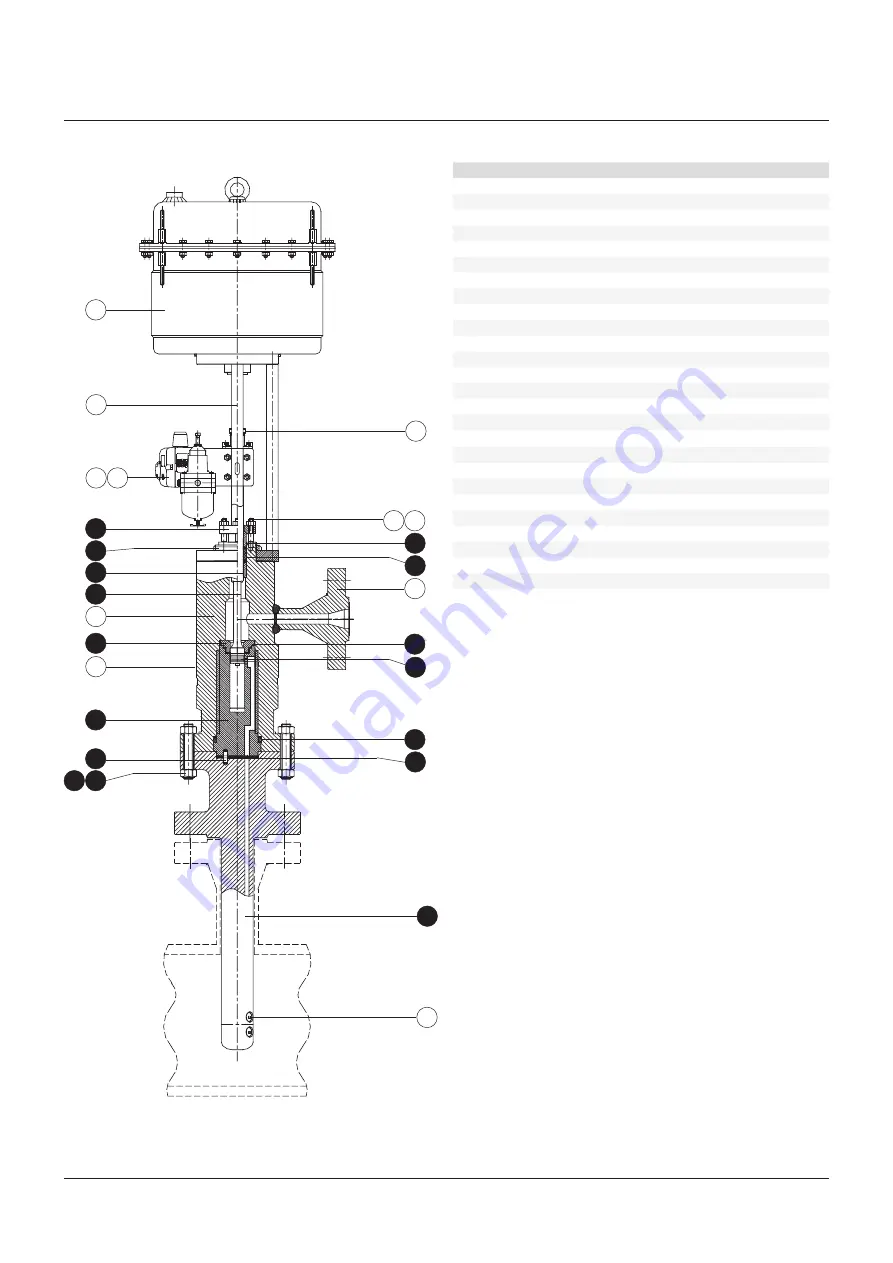

FIgure 10

Model 59

notes

* see certified drawing

• Recommended spare part

Materials and data of units supplied, may deviate from this brochure.

please consult order documents in case of doubt.

certification

TemplowHT desuperheaters are approved by authorized authorities to comply with

the requirements of asMe B16.34 and eN. all data are subject to change.

pArts list

item

Quantity

name

Material

1

1

Body

a182 F91 / F22*

2•

1

seat

stellite 6/17% Cr*

3•

1

Control cylinder assembly

aIsI 431

4•

1

seal

ss/graphite

5•

1

gasket

ss/graphite

6•

1

stem incl. piston

aIsI 431 nitrited

7•

1

Injection probe

a182 F91 / F22*

8•

1

pin, spray cylinder

aIsI 304

9•

1

packing, set

graphite

10•

1

gland, packing

aIsI 304

11•

1

Bushing, spacer

aIsI 431 nitrited

12•

1

Bushing, gland

aIsI 431 nitrited

13

4

stud, packing gland

a193 B16

14

4

Nut, packing gland

a194 4H

15•

16

stud, injection probe

a193 B16

16•

32

Nut, injection probe

a194 4H

17

*

Nozzle

Inconel 718

18

1

Name plate

aIsI 304

19•

1

seal ring

ss/graphite

20•

1

lock nut

C-steel

21

1

Coupling

C-steel

22

1

Water flange

a182 F91 / F22*

23

1

Yoke

C-steel

24•

3

piston ring

aIsI 431 nitrited

25

1

actuator

26

1

positioner

27

1

air filter regulator

trademark

stellite

®

is a registered trademark of deloro stellite.