4

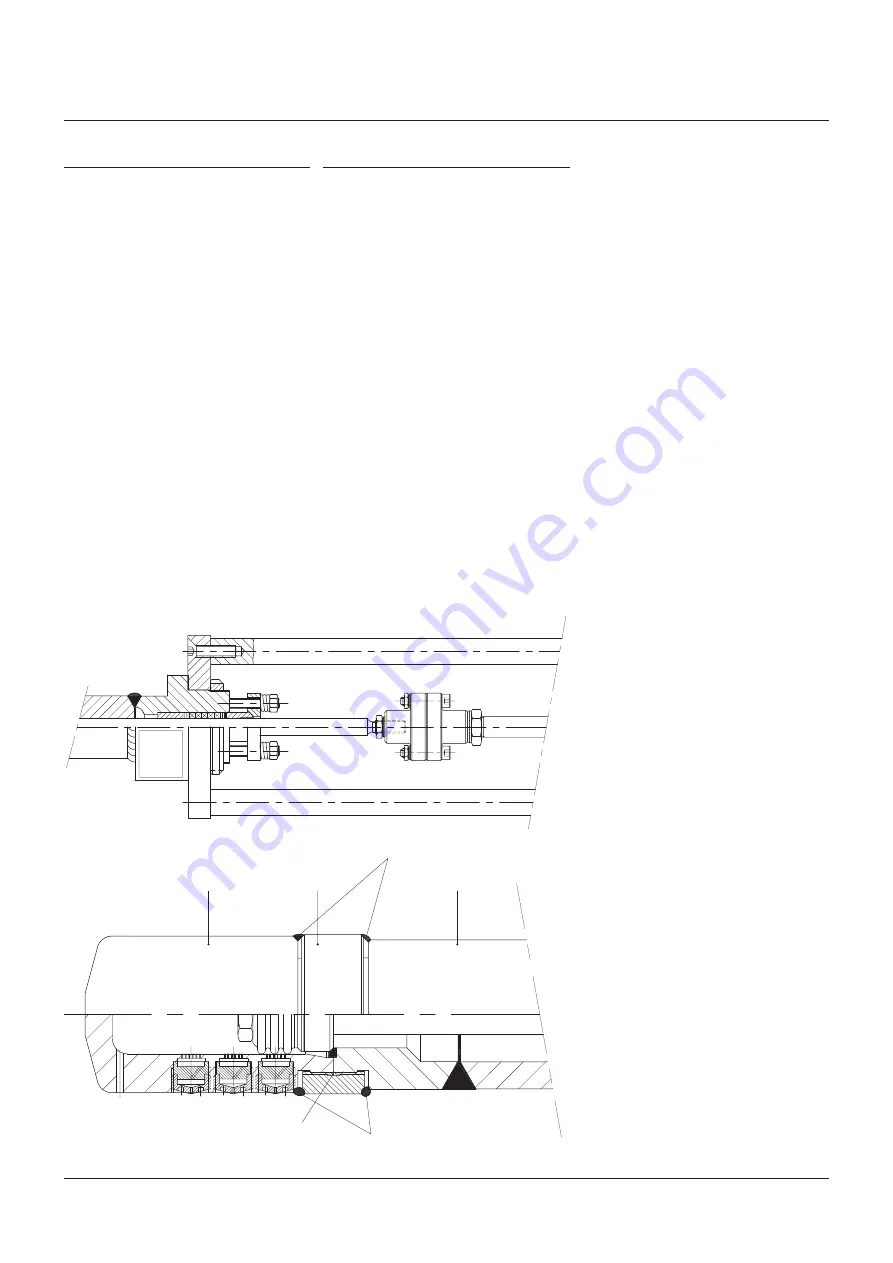

Figure 7

Figure 8

spray cylinder

Fastener ring

Tack welds

Body extension

Area lapped before assembly

Tack welds

YarwaY

A.T.-Temp CryogeniC desuperheATer sTAndArd duTy

InstallatIon and MaIntenance InstructIons

removal

Before removing the A.T.-Temp Cryogenic

desuperheater from the system, ensure that

both the process -and injection liquid pipework

are pressureless and vented.

isolate any electrical supplies to the actuator

and/or ancillaries, prior to disconnection.

Vent and remove instrument air supply piping.

Loosen process flange and liquid flange bolting,

but vent connections before complete removal.

start-Up

ensure that all components are installed

correctly. Connection of electrical supplies and

instrument air piping should be in accordance

with the manufacturer’s instruction manual.

Verify and adjust, if necessary, set points for

filter regulators and valve positioners, following

the manufacturer’s recommendations.

similarly, calibrate the temperature

transmitter/controller, verifying automatic

response to temperature changes.

Check the liquid pressure at the A.T.-Temp

Cryogenic desuperheater. Verify the operation

of the temperature transmitter and controller

by manually increasing and decreasing the

output signal and observing indicated and

recorded temperatures.

When satisfactory coordination between

instrument signals and temperature are

attained, adjustment of the set point can be

made and the system transferred to automatic

operation.

it is recommended to record the various

process coordinates, over a sustained period, to

verify operation, adjusting where necessary.

maintenance

note:

maintenance of the A.T.-Temp

Cryogenic desuperheater is straight forward

and does not require any special tools or

training. Care should be taken during any

maintenance operation, particularly when

working with grinders, compressed air and

rotating machinery. it is imperative that safety

glasses and protective workwear are used in

accordance with standard safety procedures.

in case of doubt, consult your supervisor or

safety officer before commencing any work

on the equipment.

The A.T.-Temp Cryogenic desuperheater

may now be removed from the system. it is

recommended that the A.T.-Temp Cryogenic

desuperheater is transported to a convenient

workshop which has a workbench and vice. Lift

the unit by means of straps around the body.

do not attempt to lift the A.T.-Temp Cryogenic

desuperheater by the yoke, actuator or any of

its accessories.

depending upon the type of actuator fitted,

various stem couplings are used. measure

accurately, and record the dimensions

A and B (see Figure 7) for reassembly

purposes. Also record positions of any levers

or specials fixings, sketching if necessary,

prior to removal. if any work is required on

the actuator, then please refer to the actuator

manufacturer’s manual.