EM12-Z series user manual

6

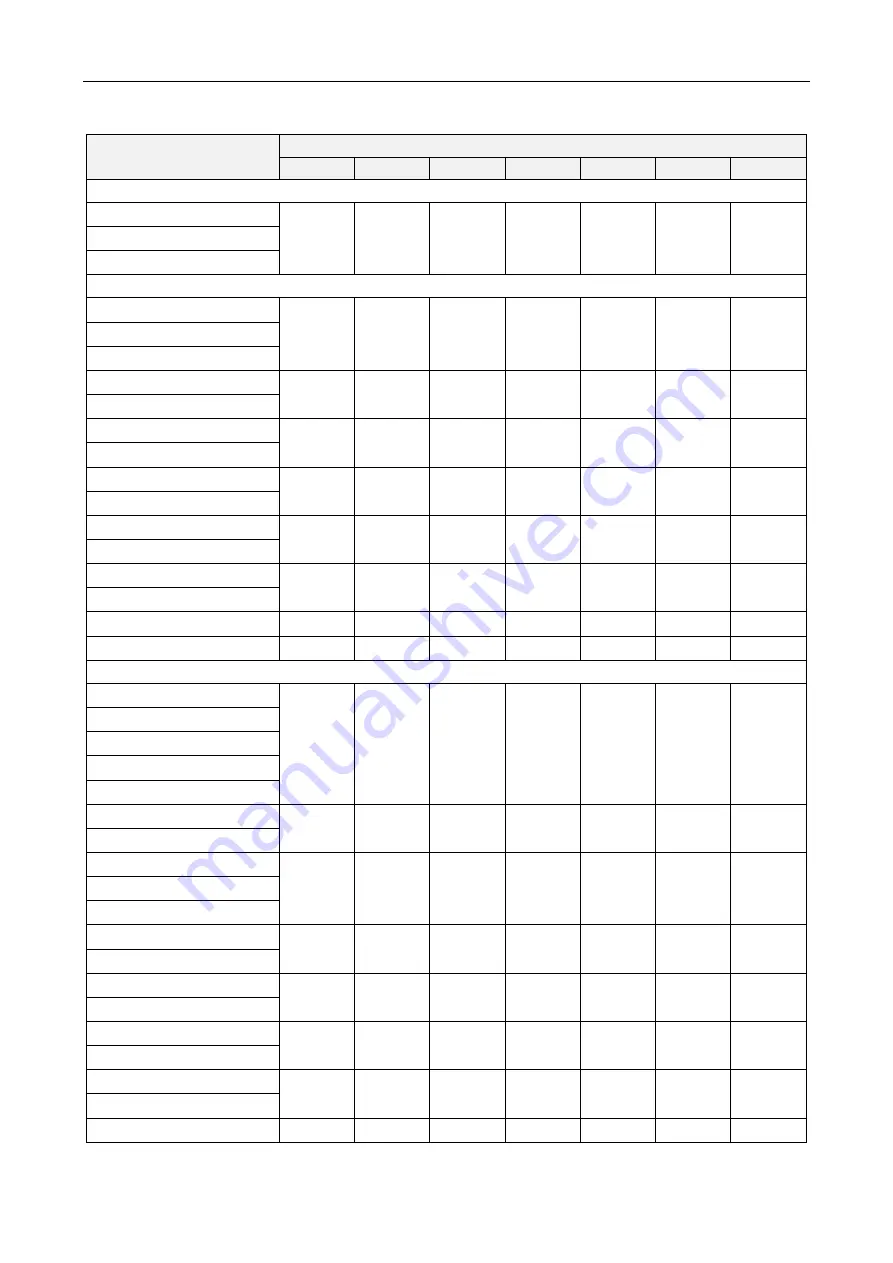

2.3.2 Appearance and Installation Hole Dimension (mm)

Model

Appearance and installation dimension

(

mm

)

W

W1

H

H1

D

D1

Φd

Single-phase 220V

EM12-Z1-d75

118

106.5

185

175.5

157

--

Φ4.5

EM12-Z1-1d5

EM12-Z1-2d2

Three-phase 220V

EM12-Z2-d75

118

106.5

185

175.5

157

--

Φ4.5

EM12-Z2-1d5

EM12-Z2-2d2

EM12-Z2-004

160

148

247

235

177

--

Φ5.5

EM12-Z2-5d5

EM12-Z2-7d5

220

205

320

305

198

--

Φ5.5

EM12-Z2-011

EM12-Z2-015

300

220

540

500

240

--

Φ7

EM12-Z2-018

EM12-Z2-022

340

260

580

540

270

--

Φ10

EM12-Z2-030

EM12-Z2-037

410

260

610

575

280

--

Φ12

EM12-Z2-045

EM12-Z2-055

460

320

710

690

335

--

Φ12

EM12-Z2-075

535

360

885

830

370

--

Φ12

Three-phase 380V

EM12-Z3-d75

118

106.5

185

175.5

157

--

Φ4.5

EM12-Z3-1d5

EM12-Z3-2d2

EM12-Z3-004

EM12-Z3-5d5

EM12-Z3-7d5

160

148

247

235

177

--

Φ5.5

EM12-Z3-011

EM12-Z3-015

220

205

320

305

198

--

Φ5.5

EM12-Z3-018

EM12-Z3-022

EM12-Z3-030

300

220

540

500

240

--

Φ7

EM12-Z3-037

EM12-Z3-045

340

260

580

540

270

--

Φ10

EM12-Z3-055

EM12-Z3-075

410

260

610

575

280

--

Φ12

EM12-Z3-090

EM12-Z3-110

460

320

710

690

335

--

Φ12

EM12-Z3-132

EM12-Z3-160

535

360

885

830

370

--

Φ12