28

29

FINAL CHECK

Operate all cooker burners on high and low flames and check that each burner ignites

properly and has a stable flame. The following may be considered to be abnormal:

• If the burners have yellow tipping.

• If the pots are sooting up underneath.

• If the burners are extinguished by opening and closing the oven door.

• If the burners fail to ignite properly.

• If the burners fail to remain alight.

• If the electrodes constantly click when burners are alight.

When satisfied with the operation of the cooker, please explain to the user the correct

method of operation. If the cooker fails to operate correctly, contact your local service

agent.

Gas checks and adjustments -igniter operation

Check that the igniter for each burner successfully ignites the gas and that the burner

remains alight. If an igniter fails to work or a burner fails to remain alight, first remove the

plug from the electrical power outlet, and then check that all the electrical connections

are in place. If the upright cooker fails to operate correctly, call Glem Gas Appliances Pty

Ltd or their appointed agent for service.

Do not attempt repairs yourself

.

Gas checks and adjustments -pressure adjustment

First shut off the gas to the appliance. Remove the sealing screw from the regulator test

point at the rear of the cooker and attach the hose from the mamometer to the point.

Turn the gas back and light the largest burner and smallest burner at the maximum

setting. Check the pressure and adjust at the regulator if necessary to the settings in the

table or on the data plate. For propane gas adjust at the regulator at the cylinder. Turn

regulator adjusting screw clockwise to increase pressure and anti clockwise to reduce

pressure. Refit the test point sealing screw when finished.

NOTE! THIS COOKER MUST BE INSTALLED BY A LICENSED GAS FITTER.

WRITTEN PROOF IS REQUIRED FOR WARRANTY SERVICE.

STANDARD PLUMBERS TEFLON TAPE SHOULD NOT BE USED TO SEAL

JOINTS. AN APPROPRIATE GAS SEALING TAPE OR COMPOUND SHOULD

BE USED.

IF IN DOUBT ON ANY INSTALLATION POINTS PLEASE CALL 1300 307 917

FOR MORE INFORMATION.

GAS CHECKS AND ADJUSTMENTS - AIR SETTING

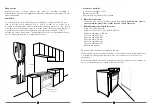

Oven burner

Check the aeration setting of the oven burner and if necessary adjust by following

these procedures. Remove the shelves and vitreous enamelled floor (taking care not to

damage the finishes). To remove the oven floor it may be necessary to remove the door

first and the 3 screws under the bottom edge of the seal. There is also a screw in the

side wall of the oven that if loosened makes the oven floor easy to remove.

Set the flame to maximum and loosen the aeration sleeve fixing screw. Rotate or slide

the aeration sleeve, depending on model, to increase or decrease the air intake. Tighten

the fixing screw. Assembly is a reversal of the above procedure.

GAS CHECKS AND ADJUSTMENTS - LOW FLAME SETTING

Check the low flame setting for each hob burner and the oven burner with the control

engaged in the minimum position.

Hob Burner

Turn the control until it engages in the minimum position and remove the control knob.

Insert a screwdriver in the adjusting screw (located to the side of the gascock shaft). To

increase the flame, turn the adjusting screw anticlockwise. To decrease the flame, turn

the adjusting screw clockwise. Adjust for a minimum, stable and clear flame. ENSURE

THE MINIMUM FLAME WILL NOT BE EXTINGUISHED BY AIR DRAUGHTS.

Oven Burner

Light the oven burner and operate at maximum for 15 minutes. Turn the control until it

engages in the minimum position and remove the control knob. Insert a screwdriver in

the adjusting screw (located to the side of the gascock shaft or in the centre of the shaft).

To increase the flame, turn the adjusting screw anticlockwise. To decrease the flame,

turn the adjusting screw clockwise. Adjust for a minimum, stable and clear flame.

Ensure the minimum flame will not be extinguished when the oven door is closed.

LPG CONVERSION

When completing the LPG conversion the bypass screw

on the oven thermostat needs to be screwed all the way

clockwise.