20

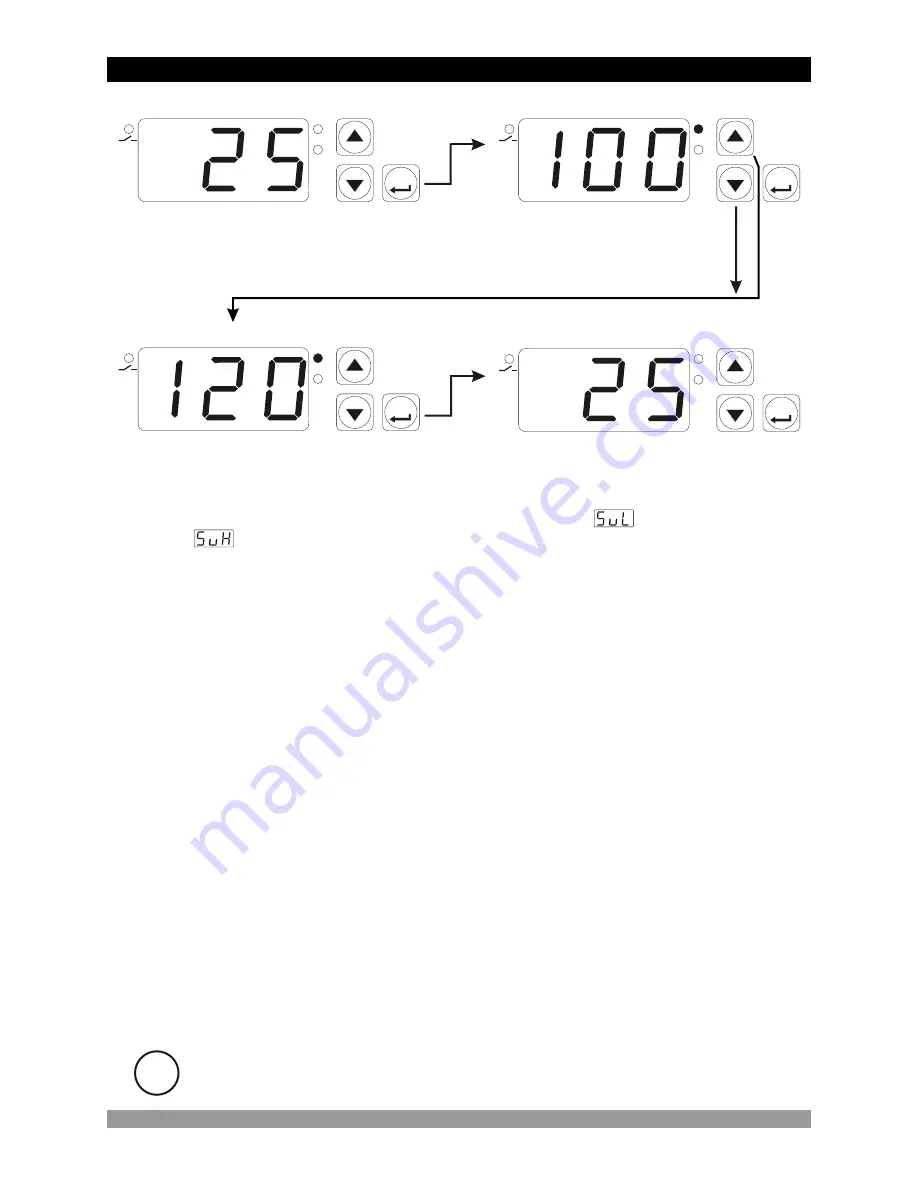

4.2 Changing and Saving Set Value

SET

°C

SV

P

When SET button is pressed, SV LED

lights on and SET value is shown on

the displays.

SET

°C

SV

P

SET Value Screen

Change the SET value with

increment and decrement

buttons.

SET

°C

SV

P

Press SET button for saving the

SET value

SV LED lights off and main operation

screen is shown.

SET

°C

SV

P

Main Operation Screen

SET Value Screen

i

If no operation is performed in Set value mode for 20 seconds, device turns to main

operation screen automatically.

SET value is can be adjusted from minimum set value parameter to maximum set value

parameter , Which can be accessed from programming parameters.

Main Operation Screen