19

Explosion Hazard

Use a new CSA or UL approved

gas supply line.

Install a shut-off valve.

Securely tighten all gas

connections.

Examples of a qualified

person include licensed

heating personnel, authorized

gas company personnel, and

authorized service personnel.

Failure to do so can result in

death, explosion, or fire.

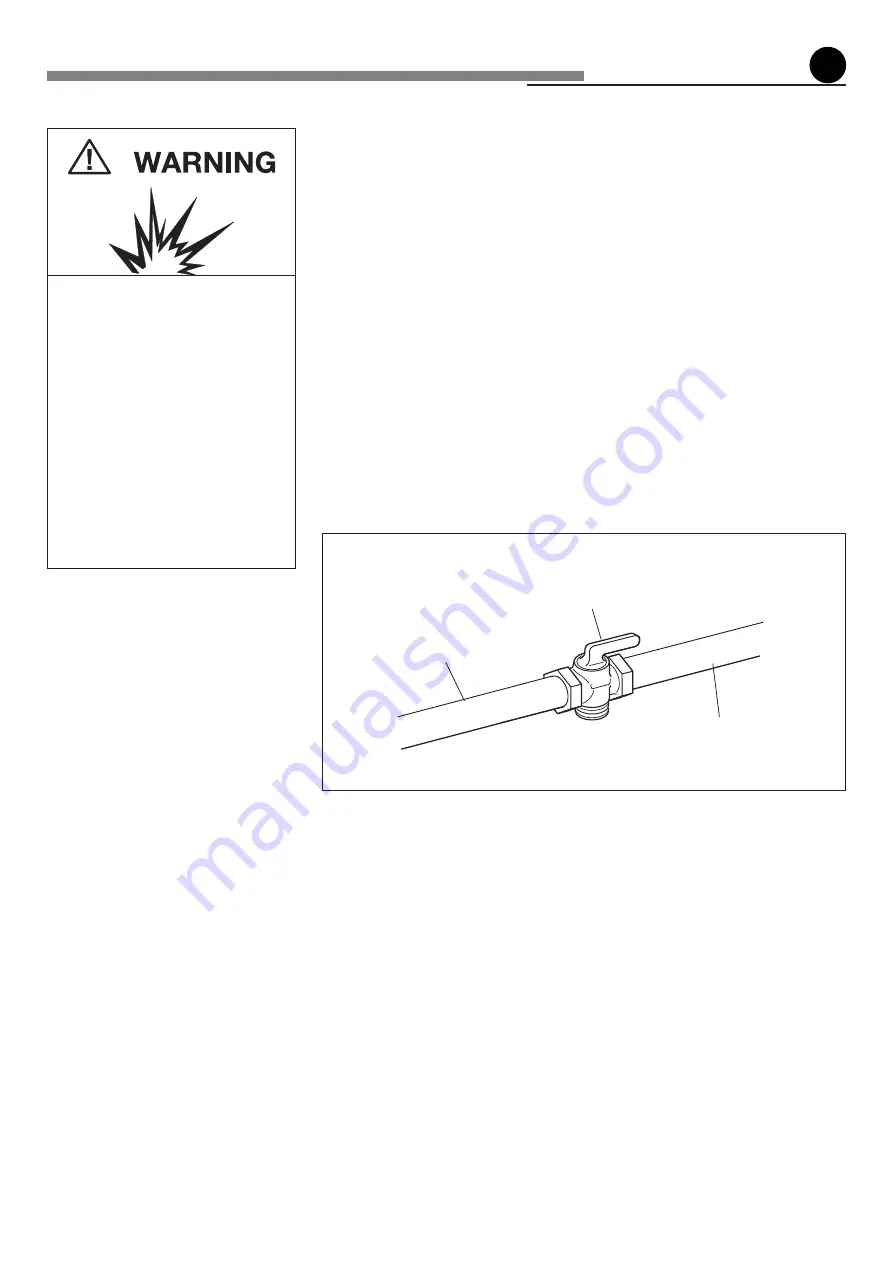

Gas supply line

Shutoff valve

“open” position

To oven

Fig. 6.1

All gas connections must be made according to national and local codes. This gas

supply (service) line must be the same size or greater than the inlet line of the

appliance. Sealant on all pipe joints must be resistant to the action of LP/Propane gas.

The oven is equipped for the use with NATURAL gas. It is design-certified by CSA

International for NATURAL.

The model/serial rating plate, located on the back of the oven, has information on

the type of gas that can be used. If this information does not agree with the type of

gas available, check with the local gas supplier.

1. Manual Shut-off Valve

(fig. 6.1)

:

A manual shut-off valve must be installed in an accessible location in the gas line

external to the appliance for the purpose of turning on or shutting off gas to the

appliance (In Massachusetts such shutoff devices should be approved by the Board

of State Examiners of Plumbers & Gas Fitters). This valve should be located in the

same room as the oven and should be in a location that allows ease of opening and

closing (in a position where it can be reached quickly in the event of an emergency).

Do not block access to the shutoff valve. The valve is for turning on or shutting off

gas to the appliance.

2. Pressure Regulator:

a) All heavy duty, commercial type cooking equipment must have a pressure regulator

on the incoming service line for safe and efficient operation, since service pressure

may fluctuate with local demand.

6

GAS CONNECTION

b)

The oven is suitable for the use of natural gas.

c) Manifold pressure should be checked with a manometer; NATURAL gas requires

4.0” W.C.P..

Incoming line pressure upstream from the regulator must be 1” W.C.P. higher than

the manifold pressure in order to check the regulator.

The regulator used on this oven can withstand a maximum input pressure of 1/2

PSI (14.0” W.C.P). If the line pressure is in excess of that amount, a step-down

regulator will be required.