22

7

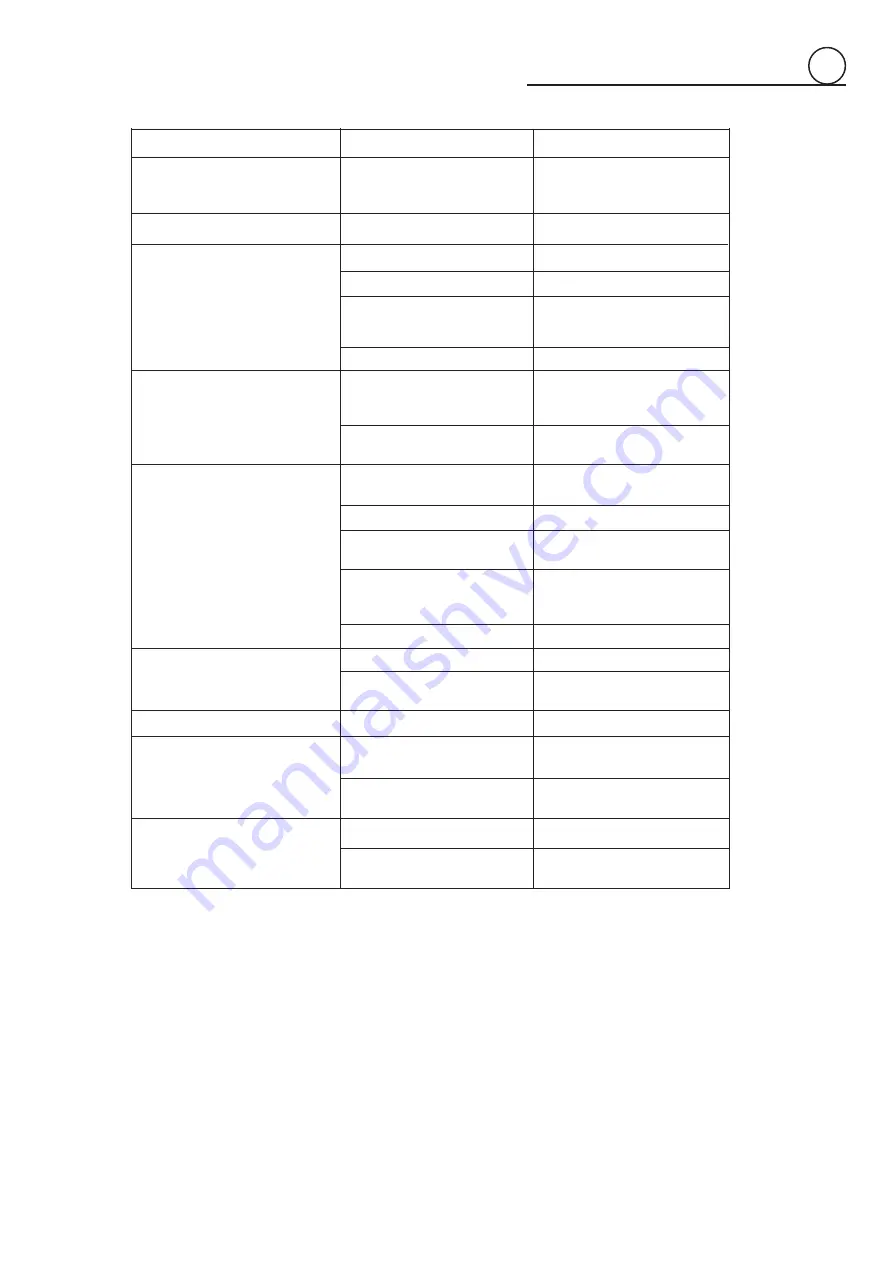

Problem Description

Possible Reason

Suggestion

Baking effect is not ideal

Grilling rack is not placed

properly

Put the grilling rack in the

appropriate layer of the

cavity and preheat the oven

Oven lamp is not lighted

Oven lamp broken

Replace the oven lamp

The oven is not lighted

Control board damaged

Self-priming valve damaged

Ignition pin offset

Ignition pin damaged

Replace the control board

Replace the self-priming valve

Adjust the installation position

of the ignition pin so that the

spark can hit the fire hole

Replace the ignition pin

Oven combustion cannot

maintain

The ion induction pin is not

installed in place

Adjust the installation of

induction pin so that the flame

can burn the induction pin

Abnormal pressure

Use the correct air supply

pressure

Flameout during use

Abnormal oven temperature

Insufficient oxygen in the

cabinet

Install cabinet with holes as

required

Ion induction pin damaged

Replace ion induction pin

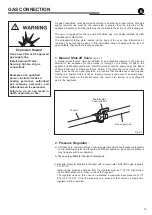

Pressure regulator does not

work Pressure is unstable

Replace the regulator

The sensing probe of

thermostat valve is not

installed in place

Adjust the sensing probe of

thermostat valve, install it on

the fixed bracket

Thermostat valve failure

Replace the thermostat valve

Fan damaged

Replace the fan

Cooling fan does not work

The thermostat controlling

the cooling fan damaged

Replace thermostat

Hot air motor does not work

Fan damaged

Replace the fan

Abnormal sound of fan

There is foreign matter in the

fan blowing the blade

Clean up foreign matters to

avoid blowing the fan blades

locking fan blade nut of hot

air motor loose

Retighten the nut

The whole machine is

powered off

Cooling fan damaged

Replace the cooling fan

Loose plug

Test plug and socket to ensure

reliable contact

VERY IMPORTANT NOTE:

The above replacement operations must be operated by professionals!

The manufacturer cannot be held re spon sible for possible inaccuracies due to printing or transcription errors in

the present booklet.

The manufacturer re serves the right to make all modifications to its products deemed necessary for manufacture

or commercial reasons at any moment and without prior notice, without jeopardising the es sential functional and

safety characteristics of the appliances.

This product is only suitable for use of natural gas. If you need to change other

types of gas, please contact:

www.empava.com

Phone:+1(888)682 8882

Email:support@empava.com

Distributed by:Empava Appliances Inc.

15253 Don Julian Rd, City of Industry, CA 91745 USA