35919-4-1015

Page 30

VERTICAL TERMINATION

Locate and mark the center point of the vent pipe using a nail on

the underside of the roof. Drive the nail through the center point.

Mark the outline of the roof hole around this center point.

NOTE:

Size of the roof hole dimensions depend on the pitch of

the roof. There must be a 1-in (25 mm) clearance to the

vertical pipe sections. This clearance is to all combustible

material.

Cover the opening of the vent pipe and cut and frame the roof hole.

Use framing lumber the same size as the roof rafters and install the

frame securely. Flashing anchored to frame must withstand high

winds. The storm collar is placed over this joint to make a water-tight

seal. Non-hardening sealant should be used to completely seal this

flashing installation.

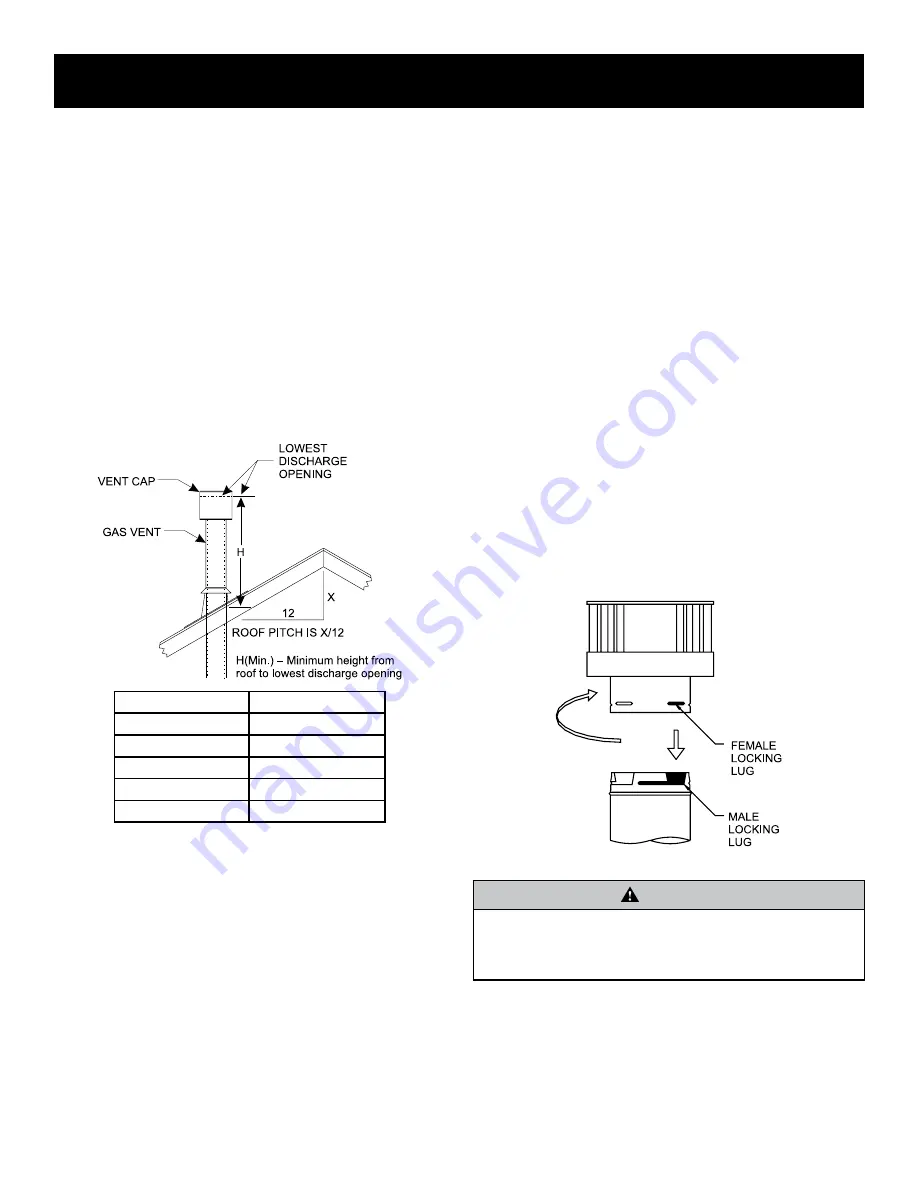

Determining Minimum Vent Height Above the Roof.

WARNING: Major U.S. building codes specify minimum chimney

and/or vent height above the roof top. These minimum heights

are necessary in the interest of safety. These specifications are

summarized in Figure 58

.

ROOF PITCH

H (Min.)

Flat to 6/12

12-in. (305 mm)

6/12 to 7/12

15-in. (381 mm)

Over 7/12 to 8/12

18-in. (457 mm)

Over 8/12 to 16/12

24-in. (610 mm)

Over 16/12 to 21/12 36-in. (914 mm)

Figure 58

Note that for steep roof pitches, the vent height must be increased.

In high wind conditions, nearby trees, adjoining roof lines, steep

pitched roofs, and other similar factors can result in poor draft, or

down-drafting. In these cases, increasing the vent height may solve

this problem.

General Maintenance

Inspect venting system semi-annually as follows:

1. Check for corrosion areas of the venting system exposed to

the elements. These will appear as rust spots or streaks and,

in extreme cases, holes. Replace damaged components should

immediately.

2. Remove the cap and shine a flashlight down the vent. Remove

any bird nests or other foreign material.

3. Check for evidence of excessive condensate, such as water

droplets forming in the inner liner and subsequently dripping

out at joints. Condensate can cause corrosion of caps, pipe and

fittings. It may be caused by having excessive lateral runs, too

many elbows and exterior portions of the system being exposed

to cold weather.

4. Inspect joints to verify that no pipe sections or fittings have been

disturbed and, consequently, loosened. Also, check mechanical

supports, such as wall straps or plumbers’ tape for rigidity.

Venting termination shall not be recessed into a wall or siding.

A removable panel or other means must be provided in the enclosure

for visual inspection of the flue connection.

NOTE: This also pertains to vertical vent systems installed on the

outside of the building.

Slide the vertical vent cap over the ends of the vent pipe and secure.

See Figure 59.

Installing the Vent System in a Chase

A chase is a vertical box-like structure built to enclose the gas

appliance and/or its vent system. Vertical vent runs on the outside of

a building may be, but are not required to be installed inside a chase.

Figure 59

CAUTION

Treatment of firestop spacers and construction of the chase may

vary with the type of building. These instructions are not substitutes

for the requirements of local building codes. Check local building

codes to determine the requirements for these steps.

NOTE:

Build the chase large enough to the minimum clearance of

combustible materials (including insulation) to the vent system. When

installing the vent system in a chase, to insulate the chase as you

would the outside walls of your home. This is especially important

in cold climates. Upon completion of chase framing, install the vent

system by following the instructions in this manual.