FG10099-3-0214

Page 16

OPERATION

Units with a Gas Control Valve

FOR YOUR SAFETY READ BEFORE LIGHTING

Figure 21 - Metro Burner Review Standard Pan with Valve

WARNING

Do not use this appliance if any part has been under water.

Immediately call a qualified service technician to inspect the

appliance and replace any part of the control system and any

gas control that has been under water.

All units with gas control valves must be lit by a Safety Pilot. For

standard units, the pilot is located at the right, rear, center of the

unit.

Follow these instructions exactly when lighting the appliance.

BEFORE LIGHTING, smell around the appliance area for gas. Be

sure to smell next to the floor, as L.P. gas is heavier than air and

will settle to the floor. Use only your hand to rotate the gas control

knob. Never use tools. If the knob will not turn by hand, do not try

to repair it; call a qualified service technician or installer. Force or

attempted repair may result in a fire or explosion.

WARNING

All gas burning appliances produce smoke and carbon mon-

oxide gas during operation. These fumes can be harmful if the

appliance is used in any other than a fully vented fireplace.

WARNING

A fireplace screen must be in place when this appliance is

in operation. Unless other provisions for combustion air are

provided, the screen shall have an opening(s) for introduction

of combustion air.

WARNING

When this decorative gas appliance is used in a fireplace

equipped with a combustion air kit and glass doors, the glass

doors should remain open during log set operation. This will

maximize the radiant heat provided to the surrounding area,

and minimize overheating of any valve installation. The glass

doors may be closed when the log set is not in use.

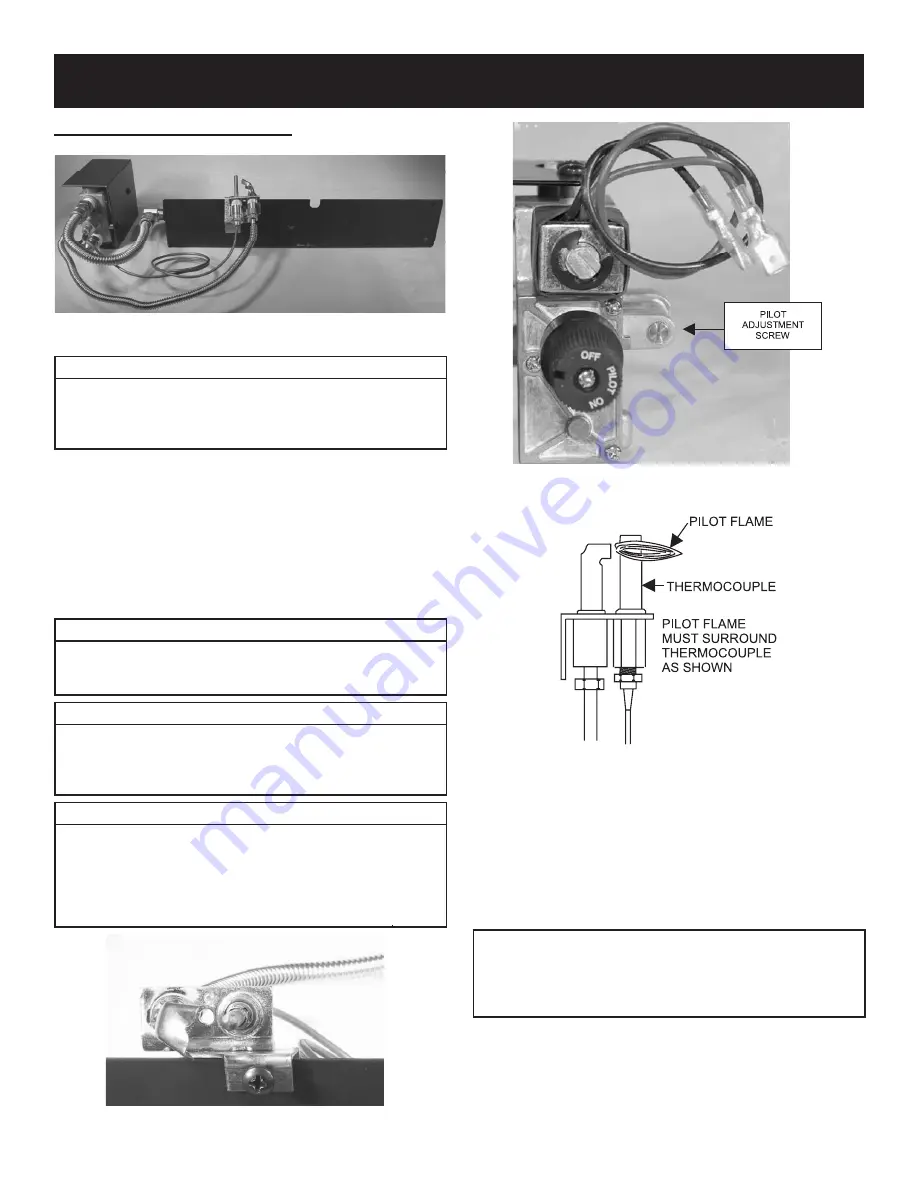

Figure 22 - Pilot Assembly, Standard Pan

Figure 23

Pilot Flame Adjustment

Figure 24

The pilot flame should be a soft blue in color and should surround

the last 1/2” of the thermocouple tip. The pilot adjustment screw

is located on the valve, just to the right of the control knob. See

Figure 23.

If the pilot flame must be adjusted, use a standard slotted screw-

driver to turn the screw clockwise to reduce the flame, or counter-

clockwise to increase the flame. See Figure 23.

Curing Refractory Gas Logs

IMPORTANT

The hard refractory gas logs provided with this decorative gas

log set require curing the first time that they are put into opera-

tion. You must follow the instructions given for curing the logs

to avoid cracking the logs with continued use.

After the initial lighting of the burner system, let the log set cool

down. Then, relight and allow to burn for another 30 minutes.