32186-0-0513

Page 15

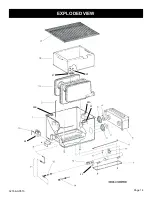

pLEAsE NOtE:

When ordering parts, it is very important that part number and description of part coincide.

pARts LIst

INdEX

NO.

pARt NO.

dEsCRIptION

3588

5088

7088

1

FF139

23226

23225

OUTER CASING

2

FF294

23216

23216

CONTROL ROD

3

FF038

FF016

FF038

FLANGE TUBE OUTLET

4

FF189

FF190

FF189

GASkET FLANGE TUBE OUTLET

5

FF066

FF032

FF027

DRAFT DIVERTER

6

FF169

FF169

FF169

LIGHTER ROD

7

FF078

FF077

FF077

DEBRIS PAN

8

FF293

FF293

FF293

VALVE BRACkET

9

FF261

P262

P262

MANIFOLD ASSEMBLY

10

FF296

FF297

FF297

PILOT TUBING WITH FERRELLS

11

762141

R715N

R715N

PILOT BURNER WITH THERMOPILE - NATURAL GAS

11

762247

R715L

R715L

PILOT BURNER WITH THERMOPILE - LP GAS

12

602032

23218

23217

BURNER

13

732010

FF250

FF250

ELECTRODE AND WIRE

14

R2313

R2313

R2313

PIEZO IGNITOR

15

742169

P8631

P8625

BURNER ORIFICE - NATURAL GAS

15

742296

P8648

P8643

BURNER ORIFICE - LP GAS

17

R5624

R5625

R5626

REGISTER

18

FF291

FF268

FF270

INNER CASING

19

FF003

FF272

FF273

COMBUSTION CHAMBER

20

DV064

DV064

DV064

PLATE FOR OBSERVATION HOLE COVER

21

DV781

DV781

DV781

OBSERVATION HOLE COVER WITH MICA

22A

R1820

R1822

R1822

REGISTER LIMIT SWITCH

22B

R1821

R1821

R1821

PRIMARY LIMIT SWITCH

23

FF298

FF299

FF300

CAUTION PLATE ASSEMBLY

24

R5605

R5605

R5605

VALVE - LP GAS

24

R5606

R5606

R5606

VALVE - NATURAL GAS

25

-

FF292

-

AIR SHUTTER (LP ONLY)

Not Shown

R1081

R921N

R921N

PILOT ORIFICE - NATURAL GAS

Not Shown

R1089

R921L

R921L

PILOT ORIFICE - LP GAS

Not Shown

R942

672010

672010

THERMOPILE