12434-7-0706

Page 10

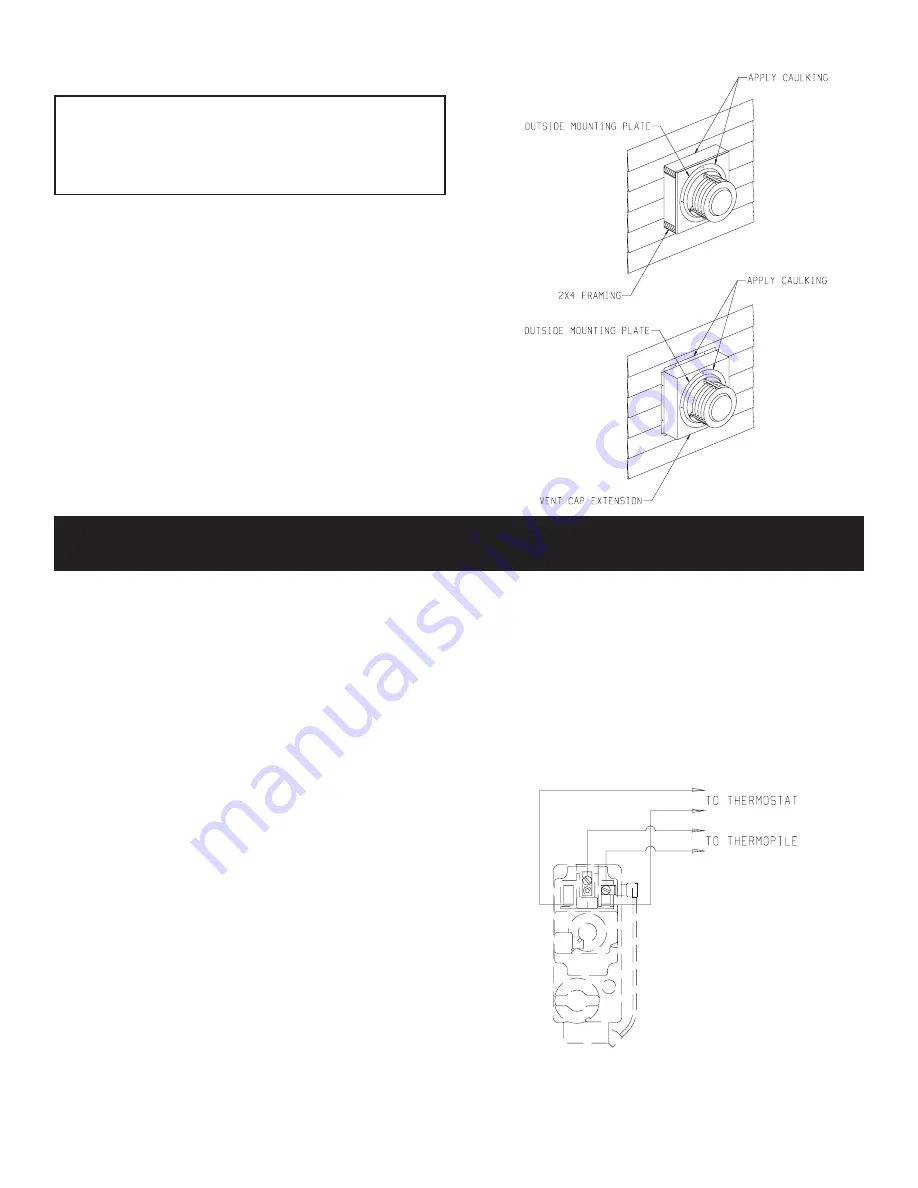

cap extension should not exceed a total depth of 13" (330mm) for

DV-25 and DV-35. (See Figure 5a)

Warning:

When vinyl siding vent kit, DV-822 or 2" x 4"

(51mm x 102mm) framing is added to an existing installation

(furnace is installed) do not attempt to add sections of pipe to

the flue outlet tube or air inlet tube. An air tight seal is required

for both tubes. Refer to Parts List, page 14 to order tubes.

Millivolt wall thermostats are specially designed for use on self-

generating systems. They should never be used on line or low

voltage A.C. circuits.

Interior Wall

— The thermostat should be installed on an inside

wall away from the furnace but in the same room.

Note:

Use 16 gauge wire to prevent excessive loss of millivolts.

Proper operation depends on a good pilot flame. The flame must

cover the top of the thermopile. Cleaning of the pilot orifice and

burner may be required due to spiders.

System Check (Figure 6)

A millivolt meter is required to check the system. Millivolt readings

should be:

• Across the thermopile terminals, 400-450 millivolts with

thermostat OFF.

• Across the thermopile terminals, 150-250 millivolts with

thermostat ON.

• Across the thermostat wires at the valve, less than 30 millivolts

with thermostat ON.

• Across the thermostat wires at the thermostat, less than 5 millivolts

with thermostat ON. (Strong winds, dirty pilot and low pressure

will reduce readings.)

Piezo Pilot Ignitor Instructions

Depressing the red button completely causes a spark to occur at

the pilot. This is a substitute for a match which requires opening

the pilot hole cover.

To light the pilot, it is important that the electrode be 1/8" (3mm)

from the thermopile. The spark must occur at the point the burner

flame hits the thermopile. The end of the electrode will be red hot

with the pilot on.

On a new installation with air in the gas line, it is suggested that a

match be used. The match will light the pilot faster than the piezo

under this condition.

Figure 5a

Figure 5

Figure 6

THERMOSTAT LOCATION