13281-9-0709

Page 16

TRIAL FOR IGNITION

Pilot Ignition

Following call for heat (system start on S8600H), the module

energizes the first main valve operator. The first main valve opens,

which allows gas to flow to the pilot burner. At the same time, the

electronic spark generator in the module produces a 13,000 volt

spark pulse output (at 25 pf load). The voltage generates a spark

at the igniter-sensor that lights the pilot.

If the pilot does not light, or the pilot flame current is not at least

1.0 ua and steady, the module will not energize the second main

valve and the main burner will not light.

Safety Lockout

S8600H provides 100 percent shutoff, or safety lockout. a timer

starts timing the moment the trial for ignition starts. Ignition spark

continues only until the timed trial for ignition period ends. Then

the module goes into safety lockout. Lockout de-energizes the

first main valve operator and closes the first main valve in the gas

control, stopping pilot gas flow. The control system must be reset

by setting the thermostat below room temperature for one minute

or by turning off power to the module for one minute.

Main Burner Operation

When the pilot flame is established, a flame rectification circuit

is completed between the sensor and burner ground. The flame

sensing circuit in the module detects the flame current, shuts off the

spark generator and energizes the second main valve operator. The

second main valve opens and gas flows to the main burner, where

it is ignited by the pilot burner. The flame current also holds the

safety lockout timer in the reset (normal) operating condition.

When the call for heat ends, both main valve operators are de-

energized, and both main valves in the gas control close.

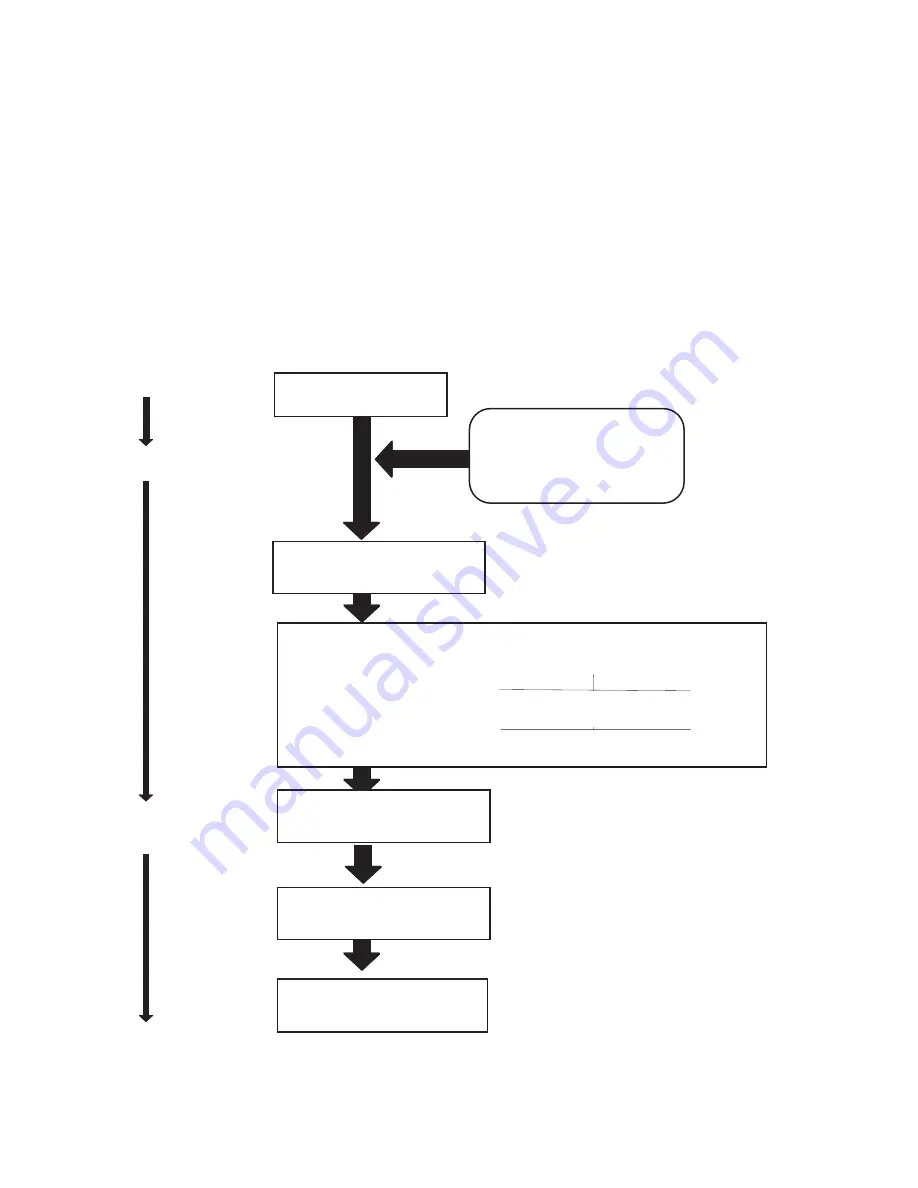

START

STAGE 1

TRIAL FOR IGNITION

STAGE 2

MAIN BURNER

OPERATION

END

THERMOSTAT

CALLS FOR HEAT

SPARK GENERATOR POWERED

FIRST VALVE (PILOT)

OPERATOR OPENS

PILOT BURNER OPERATION

PILOT BURNER LIGHTS

MODULE SENSES FLAME CURRENT.

PILOT BURNER DOES NOT LIGHT

OR

MODULE

RESPONSE

S8600H

AFTER 90SECONDS *PILOTVALVE

CLOSES, SPARK STOPS

*LOCKOUT TIMING IS STAMPED ON MODULE

IF FALME CURRENT SENSED

*SPARK GENERATOR OFF

*SECOND VALVE OPERATOR

(MAIN) OPENS.

MAIN BURNER OPERATION

MODULE MONITORS PILOT

FLAME CURRENT

THERMOSTAT SATISFIED

VALVES CLOSE.

PILOT AND MAIN BURNERS ARE OFF.

POWER INTERRUPTION

SYSTEM SHUT OFF. RESTARTS WHEN

POWER IS RESTORED.

PILOT FLAME FAILURE

SECOND MAIN OPERATOR CLOSES

MODULE STARTS TRIAL FOR IGNITION.

START

STAGE 1

TRIAL FOR IGNITION

STAGE 2

MAIN BURNER

OPERATION

END

THERMOSTAT

CALLS FOR HEAT

SPARK GENERATOR POWERED

FIRST VALVE (PILOT)

OPERATOR OPENS

PILOT BURNER OPERATION

PILOT BURNER LIGHTS

MODULE SENSES FLAME CURRENT.

PILOT BURNER DOES NOT LIGHT

OR

MODULE

RESPONSE

S8600H

AFTER 90SECONDS *PILOTVALVE

CLOSES, SPARK STOPS

*LOCKOUT TIMING IS STAMPED ON MODULE

IF FALME CURRENT SENSED

*SPARK GENERATOR OFF

*SECOND VALVE OPERATOR

(MAIN) OPENS.

MAIN BURNER OPERATION

MODULE MONITORS PILOT

FLAME CURRENT

THERMOSTAT SATISFIED

VALVES CLOSE.

PILOT AND MAIN BURNERS ARE OFF.

POWER INTERRUPTION

SYSTEM SHUT OFF. RESTARTS WHEN

POWER IS RESTORED.

PILOT FLAME FAILURE

SECOND MAIN OPERATOR CLOSES

MODULE STARTS TRIAL FOR IGNITION.

START

STAGE 1

TRIAL FOR IGNITION

STAGE 2

MAIN BURNER

OPERATION

END

THERMOSTAT

CALLS FOR HEAT

SPARK GENERATOR POWERED

FIRST VALVE (PILOT)

OPERATOR OPENS

PILOT BURNER OPERATION

PILOT BURNER LIGHTS

MODULE SENSES FLAME CURRENT.

PILOT BURNER DOES NOT LIGHT

OR

MODULE

RESPONSE

S8600H

AFTER 90SECONDS *PILOTVALVE

CLOSES, SPARK STOPS

*LOCKOUT TIMING IS STAMPED ON MODULE

MAIN BURNER OPERATION

MODULE MONITORS PILOT

FLAME CURRENT

THERMOSTAT SATISFIED

VALVES CLOSE.

PILOT AND MAIN BURNERS ARE OFF.

POWER INTERRUPTION

SYSTEM SHUT OFF. RESTARTS WHEN

POWER IS RESTORED.

PILOT FLAME FAILURE

SECOND MAIN OPERATOR CLOSES

MODULE STARTS TRIAL FOR IGNITION.

IF FLAME CURRENT SENSED

*SPARK GENERATOR OFF

*SECOND VALVE OPERATOR

(MAIN) OPENS

After 90 seconds* pilot valve

closes, spark stops

.