13281-9-0709

Page 8

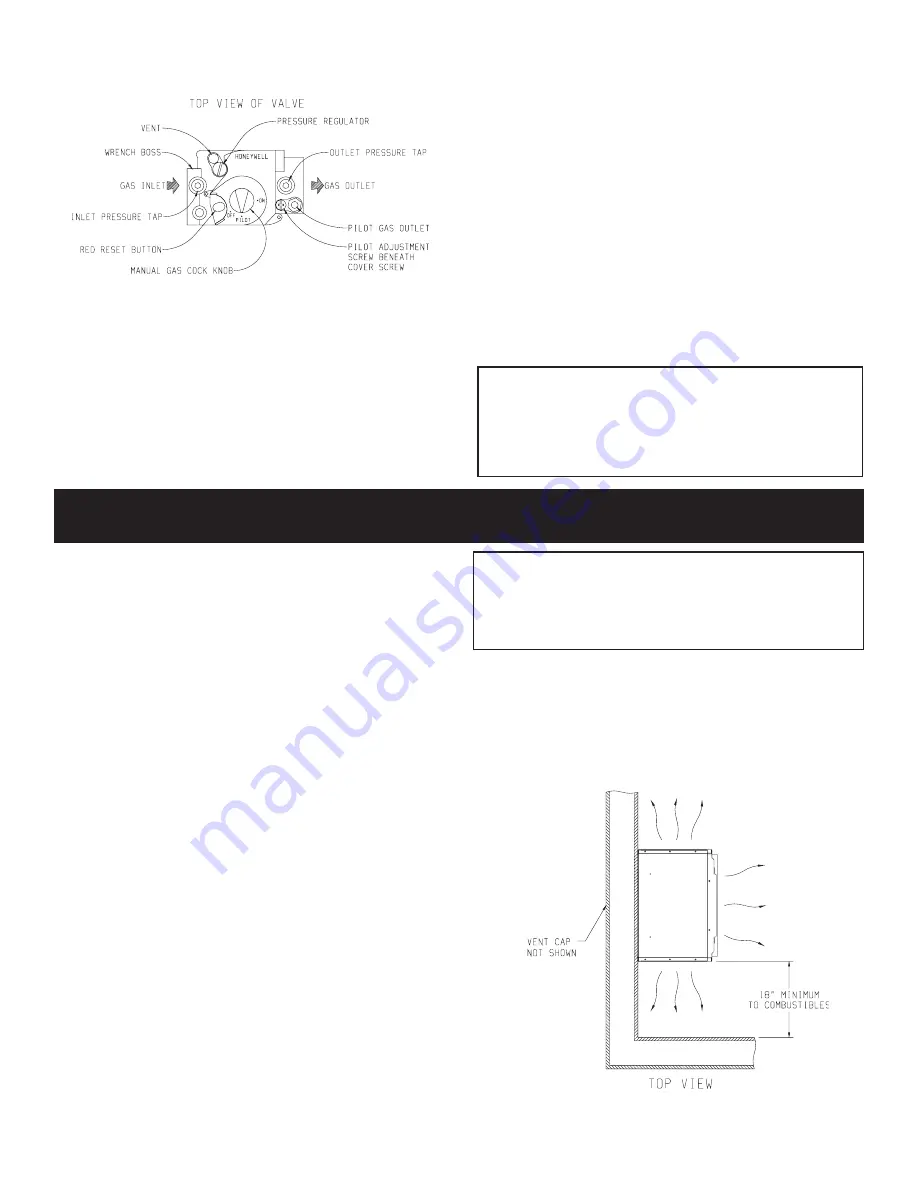

Figure 3

Checking Manifold Pressure

Both Propane and Natural gas valves have a built-in pressure

regulator in the gas valve. Natural gas models will have a manifold

pressure of approximately 3.5" w.c. at the valve outlet with the

inlet pressure to the valve from a minimum of 5.0" w.c. for the

purpose of input adjustment to a maximum of 7.0" w.c. Propane

gas models will have a manifold pressure approximately 10.0"

w.c. at the valve outlet with the inlet pressure to the valve from a

minimum of 11.0" w.c. for the purpose of input adjustment to a

maximum of 13.0" w.c.

a 1/8" N.P.T. plugged tapping, accessible for test gauge connection,

is located on the outlet side of the gas control.

The built-in regulator comes on at approximately 1/4th pressure

and full on in 10 seconds.

Safety Lockout

S8600H module provides 100 percent shutoff, or safety

lockout. If the pilot fails to light within 90 seconds, the

control system will shut down. The control system must

be reset by setting the thermostat below room temperature

for one minute or by turning off power to the module for

one minute.

Clearances

1. In selecting a location for installation, it is necessary to provide

adequate accessibility clearances for servicing and proper

installation.

2.

The DV4T-59-1, 5" to 9" wall depth is the standard vent

kit provided with the DV-55IPT. See Accessories Page 6 to

order vent kits for wall depths of 8" to 12" or 12" to 19".

The use of tubes not supplied by the manufacturer results

in unsatisfactory performance.

3. The DV-55IPT can be attached to the wall or recessed into the

wall up to 4 inches in depth but the minimum 5 inches vent/air

intake system wall depth must be maintained. example: If

furnace is recessed into the wall at a depth of 4 inches, the

minimum wall depth must be 5 inches behind the furnace.

4. The wall in which the furnace is recessed has (0) zero clearance

to the furnace sides and top.

5. When using side discharge registers, SOR-1 or SOK-1, the

furnace cannot be recessed into the wall.

6. Clearance to sidewall or combustible material is 4 inches.

7. Ceiling clearance is 4 inches.

8. Floor and rear wall clearance is (0) zero inches.

9. Clearance of 18 inches is required to sidewall or combustible

material when flush mounted SOR-1, side outlet register is

used. See Figure 4.

10. The minimum distance from the center of the vent cap to the

nearest outside corner or obstruction is 24 inches.

The vent terminal of a direct vent appliance with an input over

50,000 BTU per hour shall be located at least 12 inches from any

opening through which flue gases could enter a building. The

bottom of the vent terminal and the air intake shall be located at

least 12 inches above grade.

WARNING: The nearest point of the vent cap should

be a minimum horizontal distant of six (6) feet from any

pressure regulator. In case of regulator malfunction, the

six (6) feet distance will reduce the chance of gas entering

the vent cap.

Figure 4

CLEARANCES