12431-10-1008

Page 9

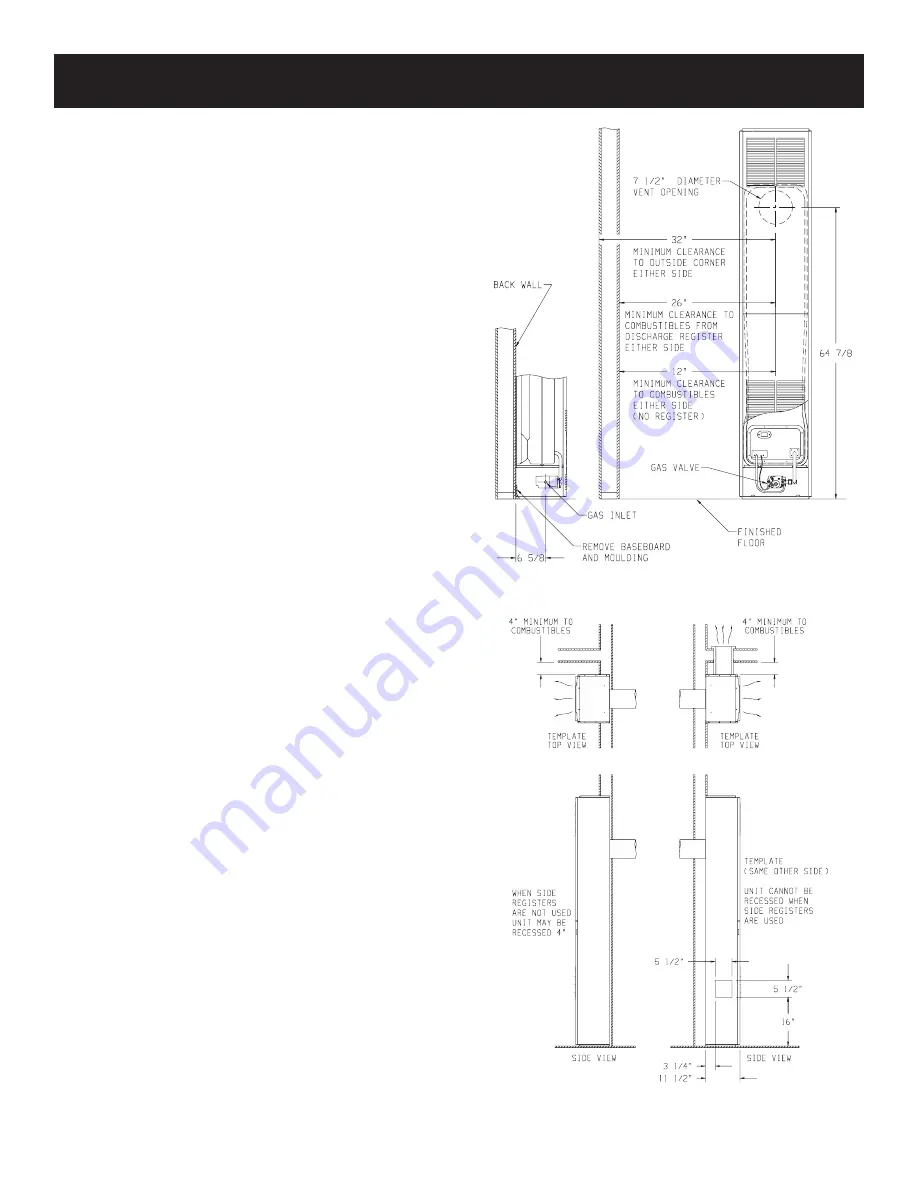

Locating Wall Opening

The furnace is to be located on an outside wall. Locate wall studs so

that wall opening will be located between wall studs. The furnace

is 16 inches in width and normal 16 inches on center studs will

not allow the furnace to be recessed into the wall unless a stud is

repositioned. The wall opening required as shown in Figure 5 is

a diameter of 7 1/2 inches.

A template is provided in furnace carton for positioning furnace

on the wall. Also, refer to Figure 5 for positioning the furnace on

wall and for locating gas line connection.

Installing Optional Side Outlets

Side outlet register, SOR-1 may be installed on one or both sides

of the furnace at the required clearances of 18 inches to adjacent

wall or combustible material as shown in Figure 4.

1. Locate and cut the 5 1/2" square opening in the cabinet side

using the template from the kit, exposing the inner liner

knock-out.

2. Remove the knock-out.

3. Place the register on the 5 1/2" opening with the louvers set

for the desired direction and mark the mounting holes using

the register as a template.

4. Drill (2) 1/8" diameter holes in cabinet side and fasten the

register in place with (2) #10 x 1" screws provided.

Side outlet kit, 10" boot assembly with register, SOK-1 for warm

air discharge into an adjoining room may be installed on either side

of the furnace at the required clearance of 4 inches to adjacent wall

as shown in Figure 7.

1. Locate and cut the 5 1/2" square opening in the cabinet side

using the template from the kit, exposing the inner liner

knock-out.

2. Remove the knock-out.

3. Using the inner and outer boots as hole templates, mark and

drill (8) 1/8" diameter holes in the inner liner and cabinet

side.

4. Using Figure 7 locate and cut a 6 3/4" square opening through

walls.

5. Prepare wall opening for the vent-air intake system (see

Locating Wall Opening

).

6. With furnace in place, after checking alignment of side outlet

opening in wall and furnace, place the 9 3/8" x 9 3/8" side

outlet wall plate over outer boot, pass the outer boot through

the wall and attach side outlet wall plate to furnace side of

wall with (2) #10 x 1" screws provided.

7. Fasten outer boot to the cabinet side with (4) #8 x 1/4"

screws provided.

8. Position and attach inner boot to inner liner with (4) #8 x

1/4" screws provided.

9. Locate the register with its louvers positioned for the desired

air discharge direction and mark the mounting holes using

the register as a template.

10. Drill (2) 1/8" diameter holes in the wall and fasten the register

in place with (2) #10 x 1" screws provided.

Figure 5

Figure 6

Figure 7

INSTALLATION INSTRUCTIONS