40946-0-1019

Page 12

These heaters are specially designed for use on self generating

systems. They should never be used on line or low voltage A.C.

circuits.

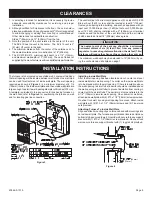

Installing the ON/OFF Device

To install an ON/OFF device (such as a wall switch, remote, toggle

switch,or thermostat), remove the wire nut from the two wires from

the valve. Run additional wire from the valve wires to the ON/OFF

device. Install the ON/OFF device in the same room as the furnace

following the installation instructions supplied with it. In the absence

of instructions, install the ON/OFF device 4 to 5 feet above the floor

on an interior wall not affected by another heating source (i.e. stove

or water heater) or the temperature of an adjoining room..

System Check

A millivolt meter is required to check the system. The millivolt

readings should be:

• Across the thermopile terminals, 400-450 millivolts with the

heater

OFF.

• Across the thermopile terminals, 150-250 millivolts with the

heater

ON.

• Across the wires at the valve, less than 30 millivolts with the

heater ON.

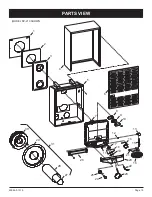

Steps in Removing Main Burner, Orifice and Valve

1. Disconnect the thermopile and pilot supply line at the pilot burner.

2. Remove the burner compartment cover 5/16" (8mm) socket

suggested.

3. Remove screw holding left side of burner and lift out.

4. Main burner orifice is now accessible. Use 1/2" (13mm) box end

wrench to remove and apply non-hardening pipe dope sparingly

to orifice threads when replaced.

5. To remove the entire gas valve the nut holding the orifice fitting

to the chamber must be removed and the gas supply to the

valve disconnected. After this, the valve and orifice elbow can

be removed as a unit.

Cleaning The Pilot Burner

Proper operation depends on a good pilot flame. The flame must

cover the top of the thermopile. Cleaning of the pilot may be an

annual necessity due to spiders. After removing the supply tubing

and orifice, use a pipe cleaner or wire to clean the entire internal

part of the pilot.

Cleaning the Combustion Chamber and Main Burner

When the main burner and vent cap are removed, all internal areas of

the combustion chamber are accessible for cleaning with a vacuum

hose. The main burner may be cleaned by forcing water into the

ports and the throat of the burner. The burner should be blown dry

or heated to dry all water out before reinstalling.

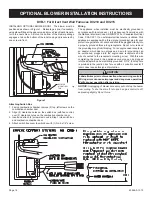

Piezo Pilot Ignitor Instructions

Depressing the piezo ignitor button completely causes a spark to

occur at the pilot. This is a substitute for a match which requires

opening the pilot hole cover.

To light the pilot, it is important that the electrode be 1/8" (3 mm)

from the thermopile. The spark must occur at the point the burner

flame hits the thermopile. The end of the electrode will be red hot

with the pilot on.

On a new installation with air in the gas line, it is suggested that a

match be used. The match will light the pilot faster than the piezo

under this condition.

To Conserve Gas: Turn off pilot when heater is not in use.

TO ON/OFF DEVICE

TO ON/OFF DEVICE

Figure 6

MAINTENANCE