40946-0-1019

Page 9

CLEARANCES

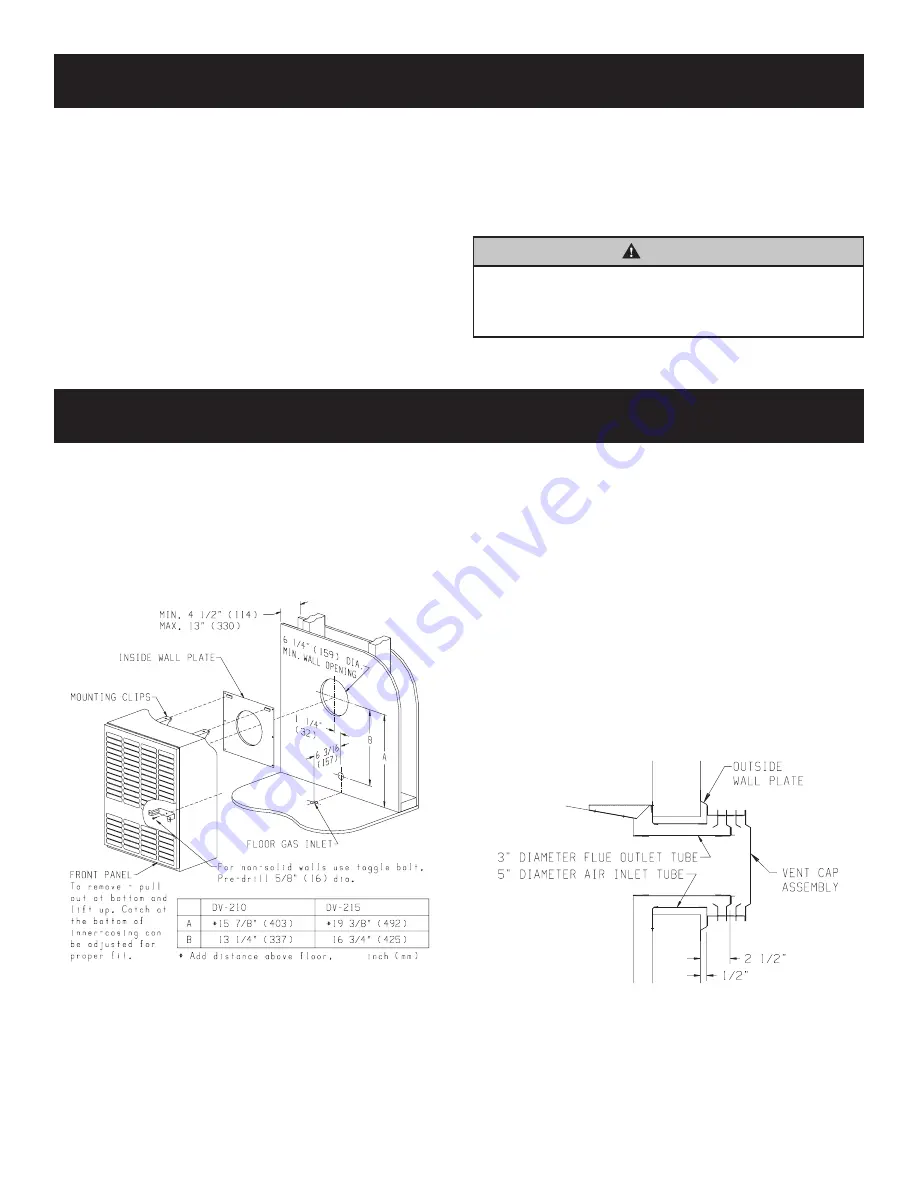

The furnace is to be located on an outside wall. Locate wall studs so

that wall opening will be located between wall studs. One wall stud

can be used for attachment of inside wall plate. The wall opening

required as shown in

Figure 3

is a minimum diameter of 6 1/4

(159mm) inches. The inside wall plate and the outside wall plate are

large enough to permit a wall opening diameter of 8 inches (203mm).

A template is provided in furnace carton for positioning furnace on

the wall. Also, refer to

Figure 3

for positioning the furnace on wall

and for locating gas line connection.

Figure 3

Installing Inside Wall Plate

After the wall opening has been located and cut, center and level

inside wall plate in wall opening. The collar on the inside wall plate

is to be placed within the wall opening. If there is insulation above

the wall opening (air inlet tube) a barrier should be installed above

the wall opening (air inlet tube) to prevent insulation from coming in

contact with the air inlet tube. The barrier must not penetrate into the

6-1/4" (159mm) diameter wall opening. On solid wall or wall stud,

attach inside wall plate with (6) #10 x 1 1/2" (38mm) screws provided.

On sheet rock wall, by using wall opening for access, attach inside

wall plate with (6) #10 x 1 1/2" (38mm) screws and (6) Tinnerman

nuts provided.

Attaching Furnace To Inside Wall Plate

Align and attach mounting clips on furnace back with mounting slots

on inside wall plate. The furnace support bracket located at furnace

bottom is to be secured to wall. On solid wall, secure furnace support

bracket with (1) #10 x 1 1/2" (38mm) screw provided. On sheet rock

wall, secure furnace support bracket with (1) toggle bolt provided.

(64mm)

(13mm)

Figure 4

INSTALLATION INSTRUCTIONS

1. In selecting a location for installation, it is necessary to provide

adequate accessibility clearances for servicing and proper

installation.

2. Although certified for 0 clearance to the floor , the unit is held in

place by a wall bracket. Enough clearance [2" (51mm) suggested]

to allow changing or adding floor covering is recommended.

Other clearances to combustible construction:

Sides 1" (25mm) and 12" (305mm) from the top.

3. Note the position of the vent relative to the center of the unit.

The DV-210 has the vent in the center. The DV-215 vent is 2"

(51mm) off center to the right.

4. The minimum distance from the center of the outside vent to

the nearest outside corner or obstruction is 16" (406mm).

5. The DV-210/DV-215 minimum wall depth is 4 1/2" (114mm)

and maximum wall depth is 13" (330mm). The use of tubes not

supplied by the manufacturer result in unsatisfactory performance.

The vent terminal of a direct vent appliance, with an input of 10,000

Btu per hour (3 kW) or less shall be located at least 6" (150mm)

from any air opening into a building, and such an appliance with an

input over 10,000 Btu per hour (3 kW) but not over 50,000 Btu per

hour (14.7 kW) shall be installed with a 9" (229mm) vent terminal

clearance and the bottom of the vent terminal and the air intake

shall be located at least 12" (305mm) above grade.

CAUTION

The nearest point of the vent cap should be a minimum

horizontal distant of six (6) feet (1.8m) from any pressure

regulator. In case of regulator malfunction, the six feet (1.8m)

distance will reduce the chance of gas entering the vent cap.

The maximum wall depth may be extended to 19" (483mm) by us-

ing the vent extension kits listed on page 7.