CLEARANCES

use of tubes not supplied by the manufacturer results in

unsatisfactory performance.

shall be located at least 6" (150 mm)

from any opening through which flue gases could enter a

building; for appliances up to

Btu/h

The vent cap of a direct vent appliance, with an input of 10,000

Btu/h (3 kW/h) or less

50,000

(14.6 KW/h) this

distance shall be at least 9" (229 mm). The bottom of the vent

cap and the air intake shall be located at least 12" (305mm)

above grade.

WARNING: The nearest point of the vent cap should

be a minimum horizontal distant of six (6)

(1.83m) from any pressure regulator. In case of

regulator malfunction, the six (6)

(1.83m)

distance will reduce the chance of gas entering the

vent cap.

feet

feet

1. In selecting a location for installation, it is necessary to

provide adequate accessibility clearances for servicing and

proper installation. In order to that, at least 6”(152 mm)

should be left clear from the wall on right side of the cabinet

and 4” (101 mm) on left side.

2. Unit is supported by a wall support plate secured to the

wall.

3. The minimum clearances from casing to combustible

construction is 36" (914 mm) on top, 4" (102 mm) on each

side and 4" (102 mm) from the floor or from the top surface

of carpeting, tile or other floor covering and 0" (0 mm) to

rear wall.

4. The minimum distance from the center of the vent cap to the

nearest outside corner or obstruction is 16" (407 mm).

5. The MV 120, MV 130 and MV 145 minimum wall depth is

4 1/2”(114 mm) and the maximum is 12”(305 mm). The

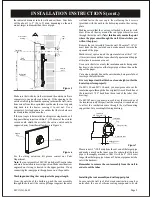

Figure 3

Vent terminal clearances

A

A

G

C

F

L

D

E

B

A=

B=

C=

D=

E=

F=

G=

H=

I=

clearance above grade, veranda, porch, deck

or balcony

clearance to window or door that may

be opened

clearance to permanently closed window

vertical clearance to ventilated soffit located

above the terminal within a horizontal distance

of 2 feet (61 cm) from the center line

of the terminal

clearance to unventilated soffit

learance to outside corner

learance to inside corner

clearance to each side of center line extended

above meter/regulator assembly

clearance to service regulator vent outlet

c

c

V

X

Vent teminal

Area where

terminal is

not permitted

Air supply

CANADIAN INSTALLATIONS

1

US INSTALLATIONS

2

12” (30 cm)

6” (15 cm) for appliances 10,000 Btu/h

(3 kW), 12” (30 cm) for appliances 10,000

Btu/h (3 kW) and 100,000 Btu/h (30 kW)

clearance in accordance with local

installation codes and the

requirements of the gas supplier

3 feet (91 cm) within a height 15 feet (4.5 m)

above meter/regulator assembly

3 feet (91 cm)

<

>

<

12” (30 cm)

6” (15 cm) for appliances 10,000 Btu/h

(3 kW), 9” (23 cm) for appliances 10,000

Btu/h (3 kW) and

0,000 Btu/h (15 kW)

clearance in accordance with local

installation codes and the

requirements of the gas supplier

<

>

5

<

clearance in accordance with local

installation codes and the

requirements of the gas supplier

Page 7

MV1XX-1-0603