36167-1-0316

Page 29

fRAMINg AND fINIShINg

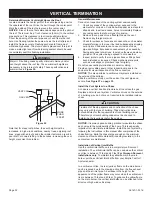

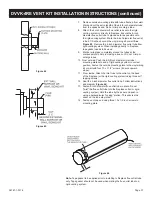

vertical firestops

Vertical runs require the use of one ceiling firestop at each ceiling

hole through which the venting passes.

Position a plumb bob directly over the center of the vertical vent

component and mark the ceiling to establish the center point

of the vent. Drill a hole or drive a nail through this center point

and check the floor above for any obstructions such as wiring

or plumbing runs. Reposition the fireplace and vent system if

necessary to accommodate ceiling joists and/or obstructions.

Cut a 10 inch x 10 inch hole through the ceiling, using the center

point previously marked. Frame the hole with framing lumber

the same size as the ceiling joists.

See figure 48.

If the area

above the ceiling is NoT an attic, position and secure the ceiling

firestop on the ceiling side of the previously cut and framed hole.

See figure 49.

If the area above the ceiling is an attic, position

and secure the firestop on top of the previously framed hole.

See

figure 50.

NOTICE

: Remove insulation from the framed area in the attic

before installing the firestop and/or vent pipes.

See Horizontal Termination Page 31 and Vertical Termination

Pages 32 - 33.

figure 48

figure 49

figure 50

See

Horizontal Termination

Page 31 and

vertical Termination

Pages 32 - 33.