Empire Abrasive Equipment Company

5.2 Weekly Maintenance

CAUTION

If your application requires aggressive media, such as aluminum oxide, garnet, or

steel grit, it is recommended that you use optional heavy duty ducting,

reclaimer lining, and DI-CARB or BORON nozzles to prevent premature wear.

Empire strongly recommends using boron carbide nozzles when blasting with

Aluminum oxide, which is the most abrasive media

.

If these options are not included with your system, they can be added. Optional

Rubber curtains for interior cabinet surfaces are also available. Consult your

Empire distributor for details.

Step 1:

Repeat the daily maintenance procedures.

Step 2:

Inspect all media-carrying hoses for wear by feeling along the length of the

hose for soft spots. Hoses with soft spots should be replaced.

Step 3:

Check the nozzle for wear. When the nozzle is worn 1/8” oversize, replace it.

A drill bit can be inserted into the nozzle to check its size.

Step 4:

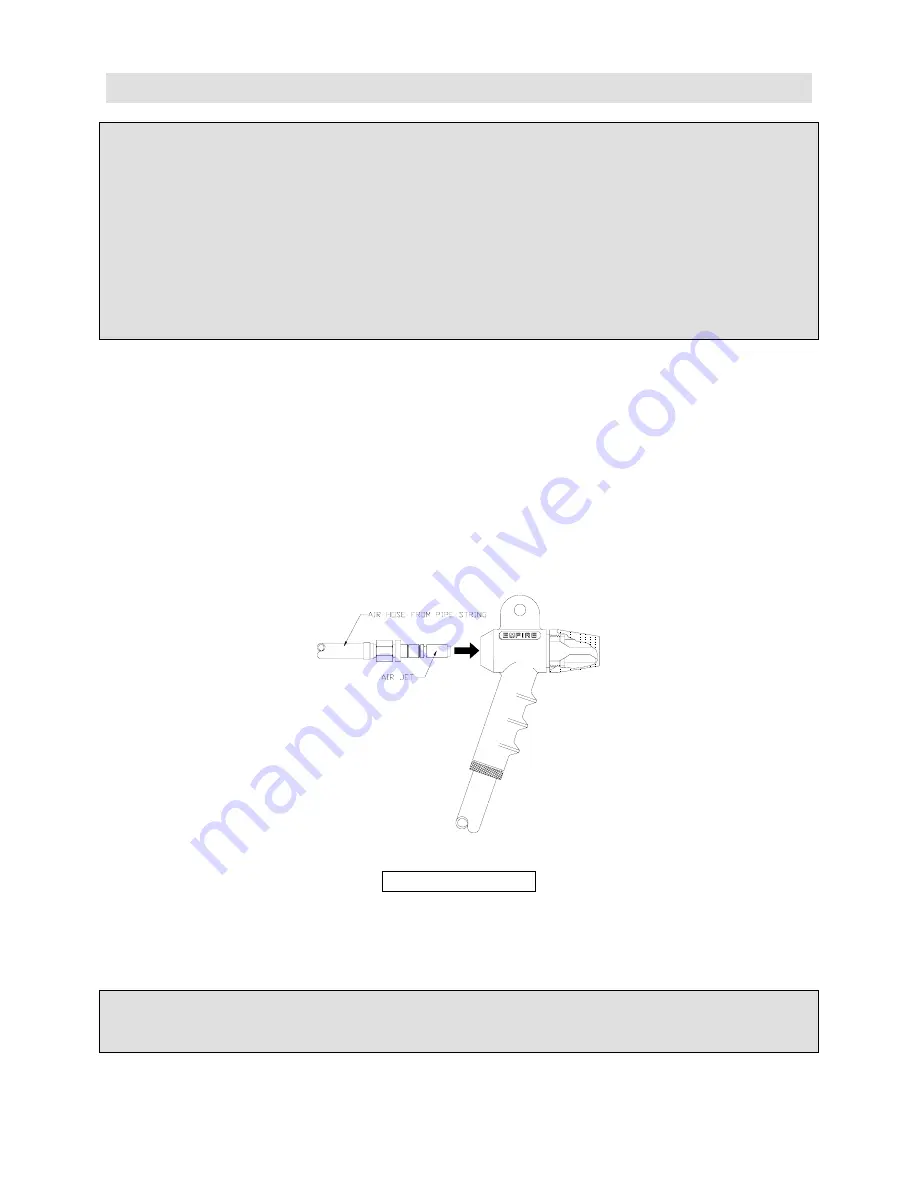

On suction systems, check the air jet for wear.

Step 5:

Loosen the set screw in the side of the gun body and remove the air jet. See

Figure 13.

Figure 13. Air Jet

Step 6:

If the air jet shows wear, rotate it 90

°

and reinsert it into the gun.

Step 7:

Re-tighten the set screw.

IMPORTANT

If an air jet is allowed to wear completely through, it will cause premature wear

of the gun body and nozzle.

Step 8:

Check the nozzle adapter and gun body for wear. Replace if necessary.

Step 9:

Check the window gaskets for leaks. Replace if necessary.

Page 29