Empire Abrasive Equipment Company

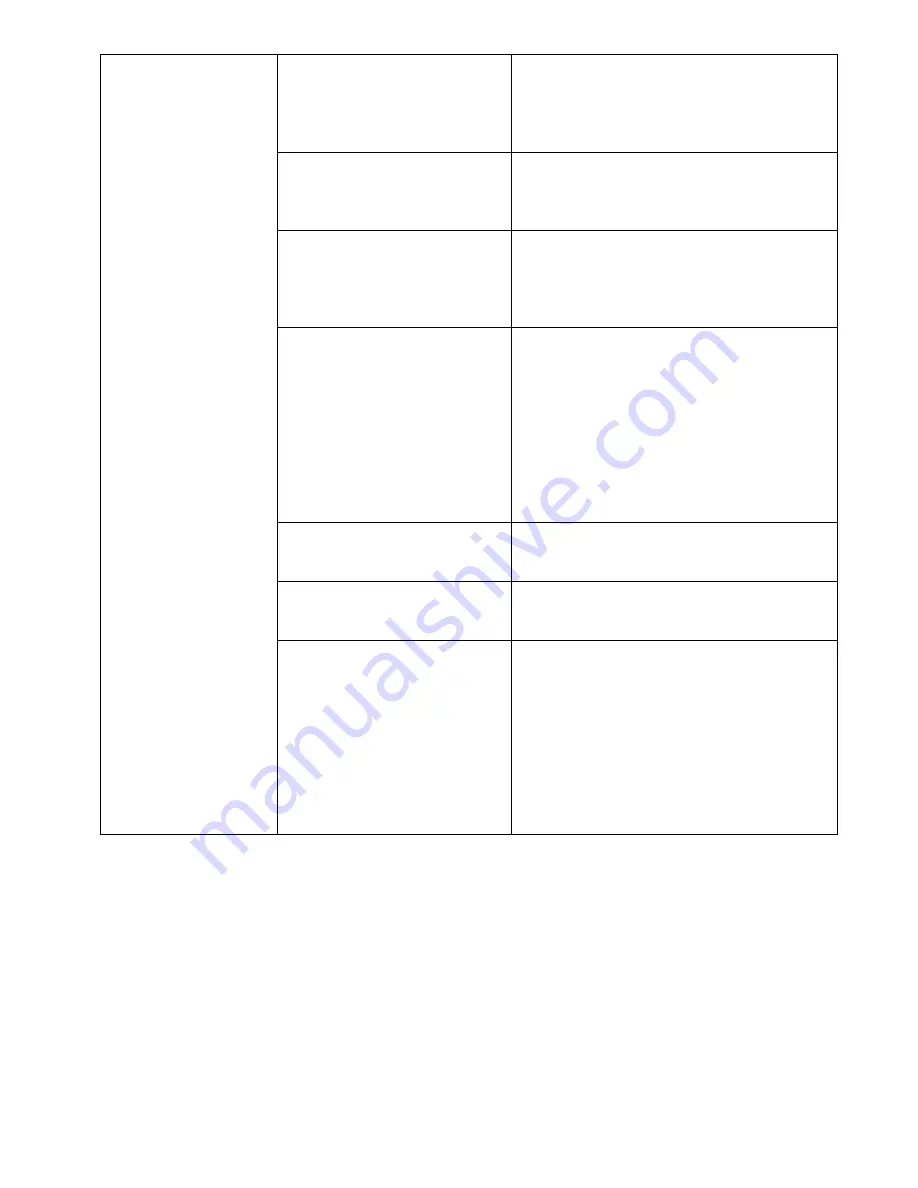

Damp media (If media

stays formed in a ball after

squeezed in the palm of

the hand, it is too damp to

flow properly).

Remove damp media from system and

replace with new, dry media. Check

compressed air supply filters. Do not

blast wet or oily parts.

Suction System:

Improper air jet nozzle

combination.

Nozzle orifice size must be twice the

air jet orifice size 1/8”diameter air jet

requires minimum ¼” diameter

nozzle.

Suction System:

Media hose improperly

installed.

Adjust media hose in media regulator.

Check media hose at entry to the

suction gun body, hose clamp nut, o-

ring, and hose must create an air

tight seal.

Suction System:

Clogged media hose.

Remove media hose from media

regulator at the bottom to the media

storage hopper, bring that end of the

hose through an open door and into

the cabinet. Remove the nozzle from

the suction gun, insert the blow-off

gun nozzle in the open end of the

media hose, and blow accumulated

media and/or debris out through the

suction gun.

Pressure System:

Sure-Flo media regulator

closed.

Adjust media regulator.

Pressure System:

Leaking sealing plunger

and/or exhaust valve.

Check for compressed air leaks and

repair.

Pressure System:

Sure-Flo media regulator

obstructed.

Open Sure-Flo media regulator to full

open, close the choke valve, remove

blast nozzle, set blast pressure at 70-

80 PSIG and attempt to blast. All air

will be forced through the media

regulator clearing the obstruction. If

media flow problems persist, shut off

and lock out compressed air supply,

disassemble media regulator and

clear obstruction.

Page 34