R-5210

Page 9

9. Remove heater from wall.

10. Remove gas valve bracket from casing assembly (4 screws to be

removed are located on casing assembly back).

11. Remove hydraulic thermostat bulb from thermostat bulb clip

located at casing assembly bottom.

12. Remove gas valve from gas valve bracket.

13. As parts are being replaced in reverse order, check for gas leaks at

all gas connections before upper louver, reflector and lower louver

are replaced onto casing assembly.

Removing Main Burner From Casing Assembly

1. Turn OFF gas supply to the heater.

2. Turn OFF electrical supply to the heater if optional blower is

installed in heater.

3. Remove lower louver from casing assembly (2 screws).

4. Remove reflector from casing assembly (2 screws).

5. Disconnect supply tubing from orifice holder(s).

6. Remove pilot bracket from main burner assembly (2 screws).

7. Remove main burner assembly from casing assembly (4 screws).

8. Remove orifice shield from main burner assembly. Attach orifice

shield to new main burner assembly.

9. As parts are being replaced in reverse order, check for gas leaks at

all gas connections before lower louver is replaced onto casing

assembly.

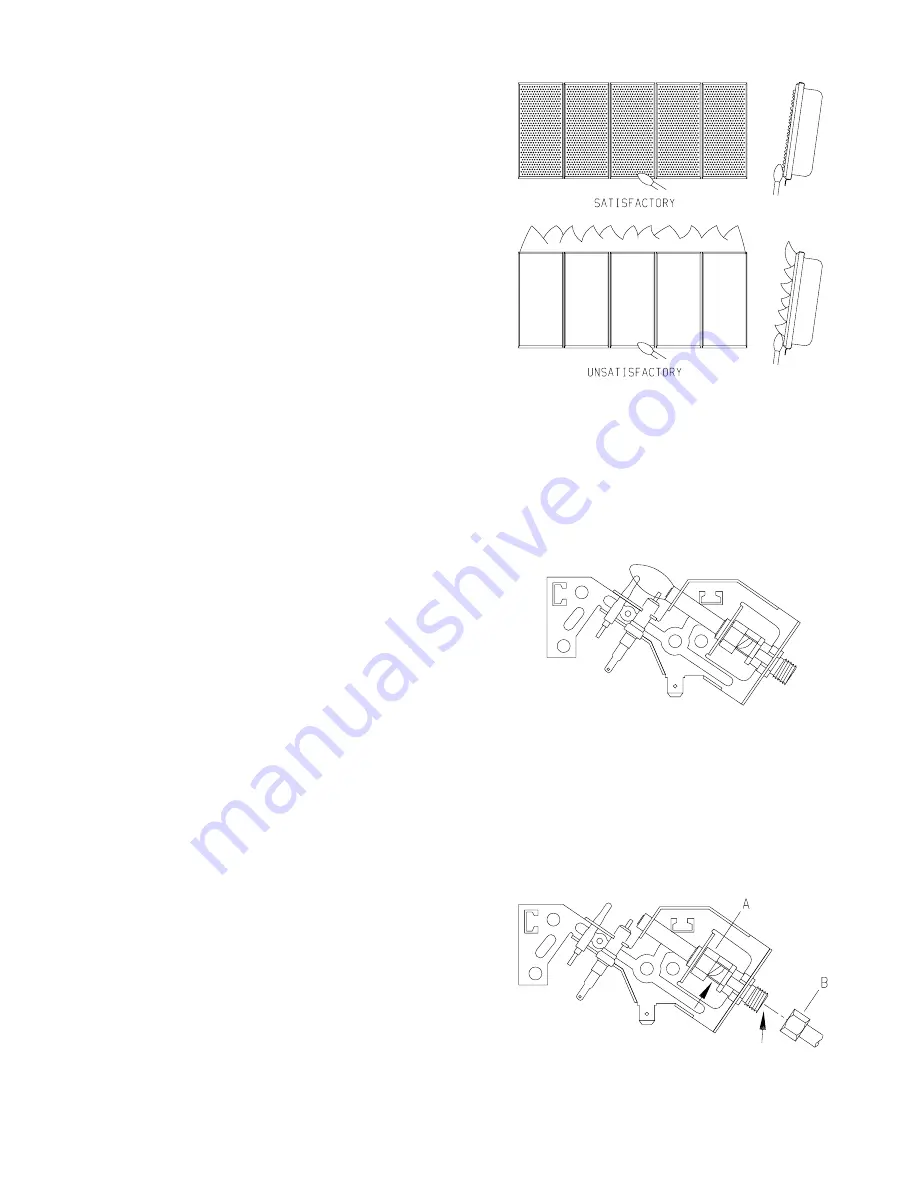

SR-10T, SR-18T and SR-30T Main Burner Flame (Figure11)

The main burner flame will have a red-orange glow over the surface of

the ceramic plaques. A few small, hairline cracks may form over the

surface of the ceramic plaques or at the edges of the ceramic plaques

where they have been cemented into position on the burner assembly

frame. These small, hairline cracks will not affect the operation or

performance of the ceramic plaques. Only, when large cracks develop,

with blue flames escaping from the large cracks, should you contact your

QUALIFIED SERVICE PERSON.

A red-orange haze that is visible on the ceramic plaques is acceptable.

A blue flame that rolls out at the top of the ceramic plaques indicates an

accumulation of dust, lint or spider webs inside the casing assembly and

main burner assembly. Use the following procedure to inspect the casing

assembly and main burner assembly.

1. Turn OFF gas supply to the heater.

2. Turn OFF electric supply to the heater if optional blower is installed

in heater.

3. Remove lower louver from casing assembly ( 2 screws).

4. Remove reflector from casing assembly (2 screws).

5. Inspect interior of casing assembly for accumulation of dust, lint or

spider webs. If necessary, clean interior of casing assembly with a

vacuum cleaner or apply air pressure. Do not damage any components

within casing assembly when you are cleaning.

6. Remove pilot bracket from main burner assembly (2 screws).

7. Pivot pilot bracket with attached pilot away from main burner

assembly (do not damage pilot tubing).

8. Inspect main burner orifice(s) through the rectangular opening(s) in

the venturi (throat) of the main burner(s). Dust, lint and spider webs

can accumulate on top of the main burner orifice(s). If necessary,

clean main burner orifice(s) with a vacuum cleaner or apply air

pressure. To thoroughly clean the main burner orifice(s) proceed to

Step 9.

9. Disconnect supply tubing from orifice holder(s).

10. Remove orifice holder from venturi of main burner assembly (1

screw for each orifice holder).

11. Remove main burner orifice from orifice holder.

12. Apply air pressure through main burner orifice and orifice holder to

remove dust, lint or spider webs.

13. Apply air pressure into ceramic plaque(s) to remove dust, lint or

spider webs.

14. As parts are being replaced in reverse order, check for gas leaks at

all gas connections before lower louver is replaced onto casing

assembly.

SR-30T SHOWN

Figure 11

Proper Pilot Flame (Figure 12)

The correct flame will be blue and will extend beyond the thermocouple.

The flame will surround the thermocouple just below the tip. A slight

yellow flame may occur where the pilot flame and main burner flame

meet.

Figure 12

Oxygen Depletion Sensor Pilot (Figure 13)

When the pilot has a large yellow tip flame, clean the Oxygen Depletion

Sensor as follows:

1.

Clean the ODS pilot by loosening nut B from the pilot tubing. When

this procedure is required, grasp nut A with an open end wrench.

2.

Blow air pressure through the holes indicated by the arrows. This

will blow our foreign materials such as dust, lint and spider webs.

Tighten nut B also by grasping nut A.

Figure 13

Summary of Contents for SR-10T-2

Page 14: ...Page 14 R 5210 SR 10T ...

Page 15: ...R 5210 Page 15 SR 18T ...

Page 16: ...Page 16 R 5210 SR 30T ...