EMPYRE PRO SERIES INSTALLATION AND OPERATION MANUAL • 2009

19

OPERATION

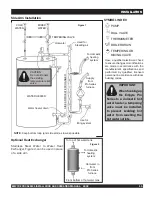

Understanding the Gasification Process of

the Empyre Pro Series Wood Furnace

Wood gasification is an amazing clean burning and

efficient process! It is a process where much of the

solid fuel is converted to gases. These gases ignite and

burn along with the solid fuel. A large percentage of

wood is converted into gases. In order for these gases

to burn up there must be the right amount of air, as well

as temperatures of well over 1000ºF. Gasification is

accomplished in the Pro Series furnace because:

a) air flow is engineered to provide the correct amount of

under fire and over fire air. This setting is calibrated for

burning seasoned wood;

b) temperatures high enough to burn the gases are

reached in the insulated chamber below the firewood.

A key factor in the gasification process is the wood itself,

the type of wood, the moisture content, diameter, length

and placement in the firebox. The Pro Series furnace

is not difficult to operate using seasoned wood and by

using the following guide it will also work well even when

using less than ideal wood.

The gases in the wood are released when the wood

surface is exposed to the fire. The more surface area of

a piece of wood that is exposed and the drier the wood

is, the faster the gases are released. Example: A small

burning DRY piece of firewood will release gases much

faster than a large WET piece of firewood.

Scenario 1: in the case of the small DRY piece of fire

wood which has lots of exposed surface area the gases

are released rapidly and the fire burns very hot but it is

starving for air due to the high volume of gases. This will

eventually create smoke.

Scenario 2: in the case of the large piece of WET

firewood that in proportion to its mass has little surface

area and will release gases slowly. In this case there is

too much air. The air is now cooling the fire resulting in

blue smoke and very little heat.

Generally speaking, when burning extremely dry

firewood, pieces should be over 5 inches in diameter in

the Pro Series 100, and over 7 inches in the Pro Series

400. If using high moisture wood, use pieces that are

less than 5 inches in diameter in the Pro 100, and less

than 7 inches in the Pro Series 400. It is good to mix

the dry and wet wood when possible. When using the

recommended seasoned wood where the moisture

content is between 19% and 25% the diameter of the

wood is not that important.

Scenario 1 is also created when stirring a hot fire.

Scenario 2 is also created when firewood is too short in

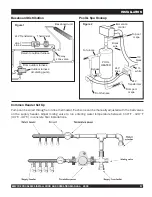

relation to the length of the firebox. Correct lengths are

as follows:

Pro Series 100 20 - 25 inches

Pro Series 200 24 - 28 inches

Pro Series 400 31 - 36 inches

Stack wood pieces side by side. If pieces are short place

them end to end making one long piece. Do NOT just

make a pile of short pieces in the firebox. Firewood

should be centered front to back over the brick slots.

Scenario 2 is also created when wood bridges in the

firebox. This is often due to wood with high moisture

or lack of careful placement of the wood. Scenario 2

is also created when starting up a cold furnace. Only a

small amount of wood is burning with a lot of excess air.

Start the fire with small pieces of dry wood and stir the

fire ensuring a good amount of wood is over ALL of the

brick slots.

Identifying Smoke Verses Condensation

Mostly the exhaust from the chimney will be clear. There

are times soon after loading the furnace when a gray

vapour may appear. This vapour disappears soon after

leaving the chimney. This vapour is moisture being

released from the wood. Smoke is more blue in colour

and will not disappear as quickly as the gray vapour. On

a cold winter day what looks like smoke may only be

vapour.

Loading Wood into the Firebox

1. The right time to add wood is when there still is

a good layer of charcoal or wood left, but not so

much that it is difficult to stir.

2. Using the ash rake, gently pull the charcoal away

from the back of the firebox. Stir the charcoal

sufficiently so that ash falls down through the

brick slots. Always ensure that the brick slots are

not blocked by ash build-up. Place wood into the

firebox, DO NOT throw, as this may damage the

brick lining.

Summary of Contents for Pro Series 100

Page 2: ......