en

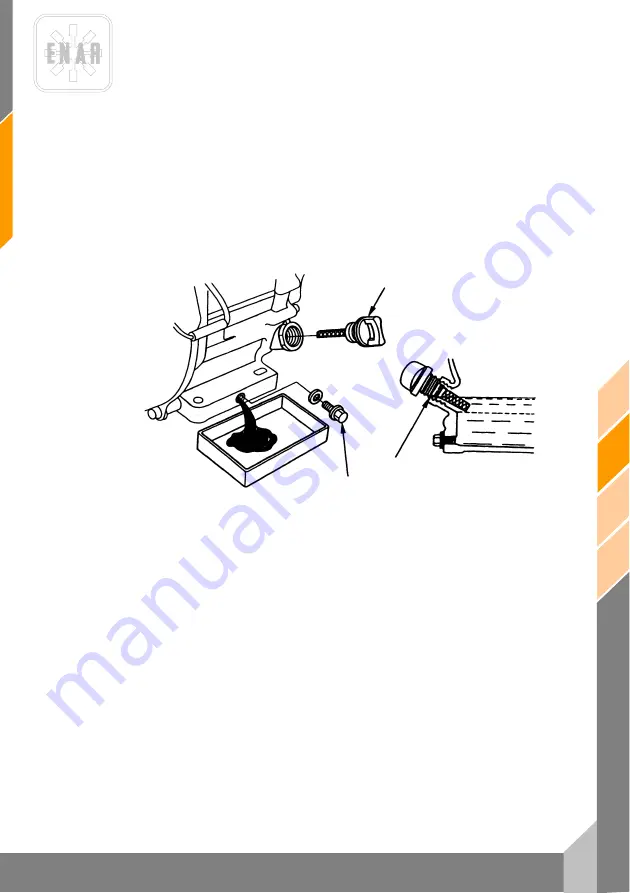

7.4 CHANGE ENGINE OIL

7.4.1.

Drain the oil when the engine is still lukewarm to make it easier to empty it quickly and

completely.

7.4.2.

Unscrew the filling cap and the drainage cap and empty the oil into a container.

7.4.3.

Screw the drainage cap tightly on.

7.4.4.

Add the recommended oil to level (see point 4.1 ENGINE DATA)

7.4.5.

Screw on the filling cap.

OILCAP/DIPSTICK

LEVEL

DRAINAGE CAP

7.5 ENGINE SPEED ADJUSTMENT

The engine must work at full load at 3600±100 r.p.m.

7.5.1.

Place the engine on a mattress

7.5.2.

Start the engine up and let it heat up for a few minutes.

7.5.3.

Tighten the acceleration stop inwards to increase the speed and slacken it to reduce the

speed it reaches. Check that the accelerator makes contact with the stop when you are

going to measure the r.p.m.

VIBRATING PLATES

17

PEN10B-PEN13C-PEN16C-PEN16D