REVERSIBLE PLATE COMPACTORS

13

en

TEN2540-TEN2550-TEN3040-TEN3050

6

OPERATION

6.1 BEFORE COMMENCING WORK

6.1.1.

Clean off all the dirt, mud, etc. from the unit before commencing work.

Special ATTENTION should be paid to the underside of the vibrating plate and the areas adjacent to

the air coolant intake for the motor, the carburettor and the air filter.

6.1.2.

Check all the screws and make sure that they are tightened properly. Loose screws can

damage the machine.

6.1.3.

Check the tension in the V-belt. Normal oscillation should be 10 – 15 mm (1/2”) when

pressure is applied to the belts halfway between the two pulleys. If there is too much play

in the belts, there may be a lack of impact or uncontrolled vibration, causing damage to

the machine.

6.1.4.

The state of the air filter.

6.1.5.

Check the oil level in the motor, and if low, top it up. The motor has a 0.6 l oil capacity.

SAE10W/40 engine oil should be used.

6.1.6.

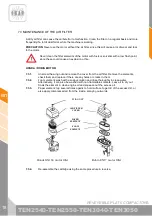

Make sure that the compaction plate is level during inspection. The oil level in the vibrator

should reach the level of the stopper. Change the oil once a month or after every 200

hours’ work. The vibrator has a 1000 cc capacity.

IMPORTANT

USE SAE 100 OIL

Change the oil while it is hot. In order to make it easier for the used oil to come out, tilt the machine

and tap the vibrator.

6.1.7.

Normal unleaded petrol should be used in the motor. When re-filling the petrol tank,

make sure the filter is in use.

6.2 STARTUP

- HONDA GX160 / ROBIN EX17 MOTOR

6.2.1.

Open the fuel cock by moving the lever to the half-open position. In order to start up the

motor when it is cold, move the lever for regulating the air to the closed position. When

the motor is hot, the air regulator should be either half or completely open. If it is difficult

to start the motor up, make sure that the lever for regulating the air is half open to stop

the carburettor from flooding due to an excessive amount of fuel.

6.2.2.

When pulling on the ignition cord, do not pull it all the way, since this could damage the

recuperator spring. Do not let go of the cord suddenly to repeat the startup procedure

once the motor has been ignited: keep hold of the handle and slowly let go until it retracts

completely.

6.2.3.

After starting up the motor, gradually open up the air control lever again. Leave the motor

to warm up at minimum speed for 3-5 minutes. This procedure for warming up the motor

with minimum revolutions is particularly important during the cold season. While the

motor is warming up, the machine should be given a general inspection to detect any

anomalies.

Summary of Contents for TEN2540

Page 2: ...HOJA EN BLANCO ...

Page 63: ...HOJA EN BLANCO ...

Page 66: ...HOJA EN BLANCO ...

Page 127: ...HOJA EN BLANCO ...