20

http://www.end.de

DG - 10/2019

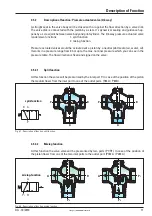

5.2

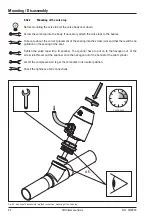

Mounting of a valve with threaded connection

Before lay on sealing compounds,check the hardly screwing by the pipes into the valve body.

Lay on the correct sealing compounds on the pipes end. By using PTFE-ribbon or hemp sealings

observe the screw direction. Don´t use sealing compounds which are not prescribed for your

employment.

Screw the pipes into the connection ends of the valves. Don´t use the pilot cylinder as a lever.

Strike up the pipes with pressure after that time the manufacturer of the sealing compounds pre-

tends for harden it.

Check the tightness af all connections.

5.3

Mounting of a valve with welded connection

By welding the valve body with the pipes observe appropriate demands and guide lines.

The safety demands by welding are depending on the place and the position of the point of weld.

Welding the parts at a serviceable device/machine/plant the potential of danger is as higher as

welding the parts in a welding room.

If appropriate, inform the shift foreman / safety engineer or the works manager and the fire

brigade of your factory

By welding observe your own national guide lines about safety and prevention of accidents.

By welding the valve between the pipes you have to take measures first, to prevent the damage

of the sealings.

5.3.1

Protection of the sealings by using Heat Absorbing Paste

To protect the seals of the of a pressure actuated valve you have to apply a amount of heat absor-

bing paste (e.g. TECHNOLIT heat absorbing paste, BLOC-IT heat absorbing paste, METAFLUX

THERMEX) to the area to be protected.

By using the heat absorbing paste you have to observe the instructions of the manufacturer.

By making multiple welding seam, the valve will have to be cool down after every working opera-

tion.

Mounting / Disassembly