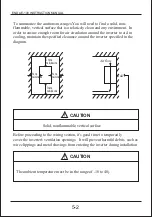

L1

L2 P RB U V W

Main Power

M

Terminal

symbol

Terminal

name

Main power

supply input

Connect the input

power supply 220V

Connect the MOTOR

Connect the braking

resistor(option)

Connect the Die-casting

(to prevent electric

shock and reduce noise)

Inverter

output

External

resistor

connection

Ground

L1, L2

U, V, W

RB, P

Function

(2) Terminal Function

¢

Main circuit Terminal

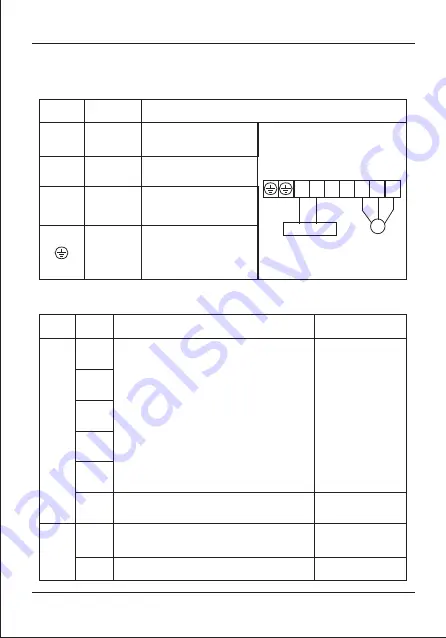

¢

Control circuit Terminal

Terminal

symbol

Terminal name

Terminal function

Signal

5

4

3

2

1

CM1

FM

CM1

Input

signal

Monitor

signal

Forward run command(FW), Reverse run

command(RV), multi-speed commands1-4

(CF1-4), 2-stage accel/decel (2CH),

Reset(RS), second control function setting

(SET), terminal software lock(SFT),

unattended start protection(USP),

current input selection(AT), jogging

operation(JG), External trip(EXT)

Common terminal for input or monitor

signal

Output frequency meter, output current

meter, output voltage meter

Common terminal for input or monitor

signal

Analog frequency

meter

contact input :

Close : ON

(operating)

Open : OFF

(stop)

minimum ON

TIME :12ms

or more

6-9

ENDA E-100 INSTRUCTION MANUAL