ENDEVCO

www.endevco.com Tel: +1 (866) ENDEVCO [+1 (866) 363-3826]

IM 2680/5 083119

22

9

If a suitable response is observed on the oscilloscope, the test is

complete.

6.3

Final electrical and mechanical installation

Prior to mounting the airborne amplifier, reinstall the potentiometer access

screw to approximately 8 in-lbs. (0.6 Nm) and solder-seal the screw per

section 3.3. Perform this function once the potentiometer is set to the

desired gain.

Once a mounting surface has been determined, drill two holes per the

outline drawings. There are some differences between the 2680 and the

2685 so make sure you are following the correct drawing. Drill and tap the

holes to accommodate the two 6-32 cap screws. When securing the cap

screws, consider the recommended torque for the screw 8 in-lb (0.9 Nm)

and the material of the mounting surface.

The accelerometer input cable should be installed with a mounting torque

of 1.5 in-lbs. (0.169 Nm), finger tight.

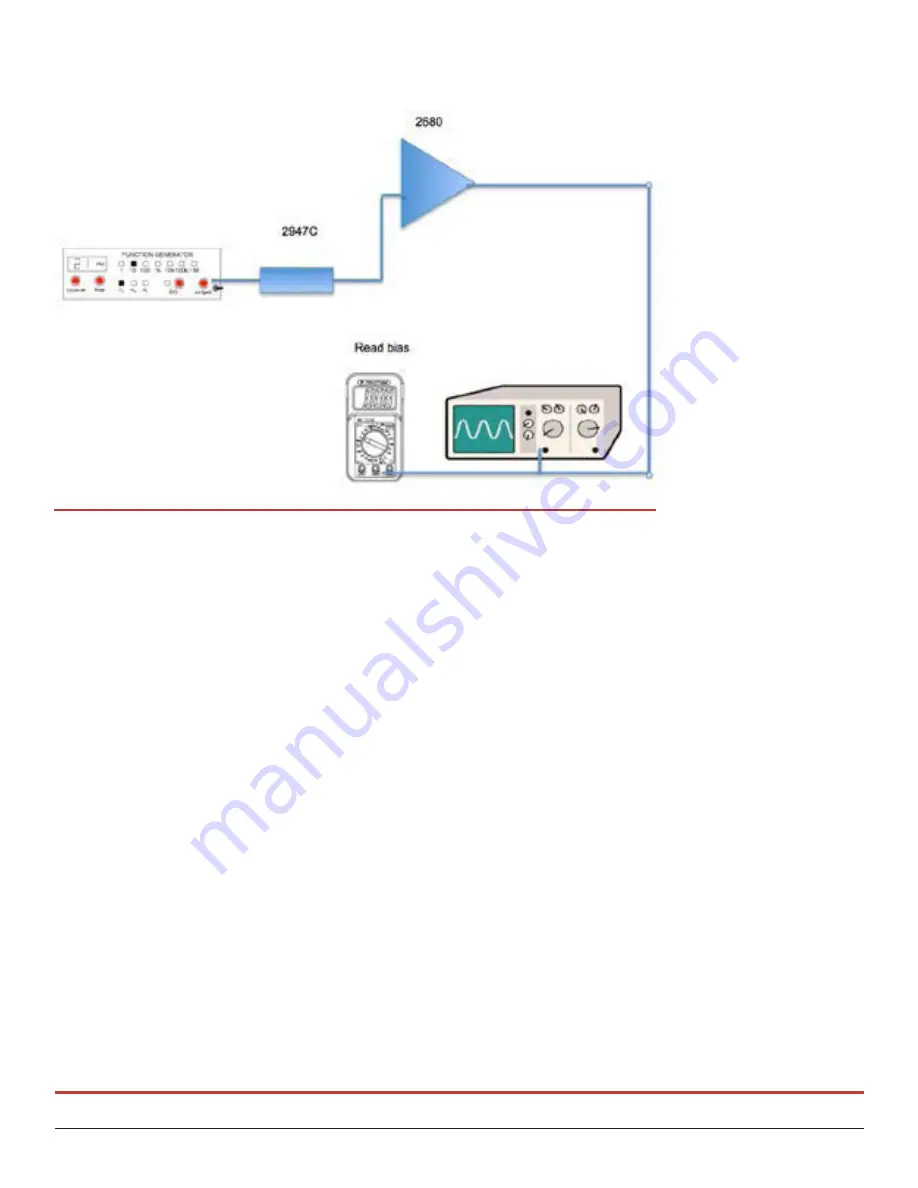

Figure 14: Test set-

up using a sine wave

voltage signal. The

2947C converts the

voltage (mV) signal

to a charge signal

(pC). The output wave

is displayed on the

oscilloscope and the

bias voltage is read on

the DMM.