Spring Balancer Users Manual

13

6-4-2 Method of attaching the tool (equipment)

WARNING

Do not move directly under the tool (equipment) suspended from the balancer.

CAUTION

Be sure to use the product within the capacity range. (Refer to the capacity range in

“4-3-1 Specifications”)

NOTICE

Adjust the spring tension before the operation.

1

Check whether the total mass (weight) of the tool (equipment) and the accessories is within the

capacity range of the balancer.

2

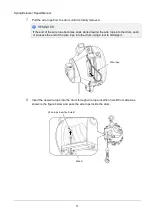

Install the tool (equipment) and adjust the spring tension in accordance with “0 Installation of

tools (equipment) and adjustment of the spring tension”.

6-4-3 Replacement of the tool (equipment) using the drum lock

WARNING

Do not move directly under the tool (equipment) suspended from the balancer.

Do not replace the tool with one with a different mass.

Do not remove the tool before checking that the drum is securely locked by

moving the tool (equipment) up and down. If the drum is locked inadequately, the

drum lock may be released during the work. Then, the wire rope may be quickly

wound up, causing an injury.

CAUTION

Be sure to use the product within the capacity range. (Refer to the capacity range in

“4-3-1 Specifications”)

NOTICE

Adjust the spring tension before the operation.

1

Confirm that the tool (equipment) can be moved up and down.

2

Lock the drum within the range of the stroke according to “6-3 Operation method of the drum

lock”, and then remove the tool.

3

Confirm that the mass of the tools is identical, and attach the tool (equipment) according to “0

Installation of tools (equipment) and adjustment of the spring tension”.

6-5 Periodical inspections

Perform an inspection at least once per month.

For the method of the periodical inspections, download “Repair Manual” from our website and refer to

“2-2 Periodical inspections” in “Repair Manual”.

http://www.endo-kogyo.co.jp

If the product is used in an unfavorable environment or used frequently, reduce the interval between

the inspections.