Installation and commissioning

HS 55 (Batch Mode)

32

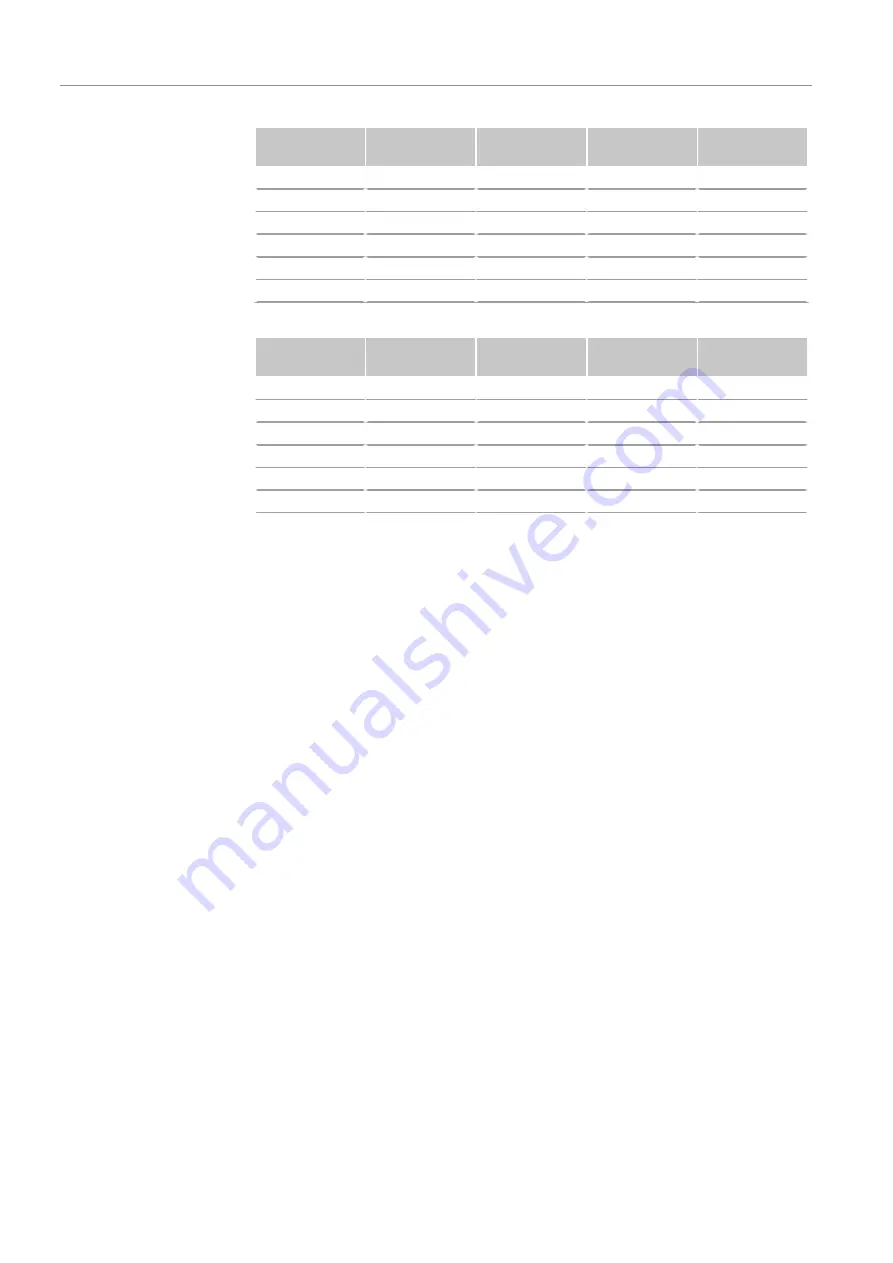

Ir coating program

Step

Temperature

[°C]

Rate [°C/s]

Hold time [s]

Purge gas

Drying

90

5

40

Max

Drying

110

1

40

Max

Drying

130

1

40

Max

Pyrolysis

1200

300

26

Stop

Atomizing

2100

500

8

Stop

Bake-out

2100

0

5

Medium

Au coating program

Step

Temperature

[°C]

Rate [°C/s]

Hold time [s]

Purge gas

Drying

80

5

25

Max

Drying

90

1

25

Max

Drying

110

5

10

Max

Pyrolysis

110

0

6

Stop

Atomizing

950

500

5

Stop

Bake-out

950

0

5

Medium

4.3.3

Installing the Hg/hydride system on the AAS

}

At the autosampler for the graphite tube furnace (AS-GF), loosen the clamping nut

of the hose guide, pull out the metering hose and deposit it in the waste bottle.

}

Insert the titanium cannula for the HydrEA system into the hose guide up to the

bend and secure it.

}

Place the Hg/hydride system near the AAS.

Electrical connection and inter-

faces

}

On the Hg/hydride system, connect the dummy plug to the cell unit temperature

sensor connection.

NOTICE! Without the dummy plug, the device emits a an acoustic signal.

}

Connect the functional module to the AAS: the AAS device provides the voltages

(+5 V/+24 V) for the functional module.

– Connect the "AAS" plug of the twin cable to the AS or Sampler Flame socket on the

AAS device.

– Connect the "HS" D-sub socket of the thinner cable of the twin cable to the "input

5 V/24 V" connection of the Hg/hydride system.

– The round green "AS" socket of the twin cable is not used.

– Connect the signal cable to the HS or the Hydridsystem connector of the AAS de-

vice. Connect the other end of the cable to the "AAS/RS 232" interface of the Hg/

hydride system.