ASP Station 2000 RPS20B

Installation

Hauser

19

Note the following when erecting the device:

• Always route the suction line so that it slopes upwards from the sampling point to the

sampler.

• The sampler must be located above the sampling point.

• Avoid siphoning effects in the suction line.

Requirements for the sampling point:

• Do not connect the suction line to pressurized systems.

• Use the suction filter to impede coarse and abrasive solids and solids which can cause

clogging.

• Immerse the suction line in the direction of flow.

• Take the sample at a representative point (turbulent flow, not directly at the bottom of the

channel).

Useful sampling accessories

• Suction filter:

Impedes coarser solids and solids which can cause clogging.

• Immersion assembly:

The adjustable immersion assembly fixes the suction line at the sampling point.

5.2

Installation

1. When installing the device, take the installation conditions into account.

2. Lay the suction line from the sampling point to the device.

3. Screw the suction line onto the device's hose connection.

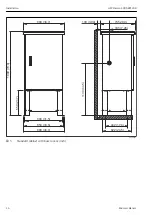

5.3

Sampling with a flow assembly

The sample is extracted either directly from the flow assembly which is installed in the base or

from an external flow assembly.

The flow assembly is used for sampling in pressurized systems e.g.:

• Tanks positioned at a height

• Pressure piping

• Conveyance using external pumps