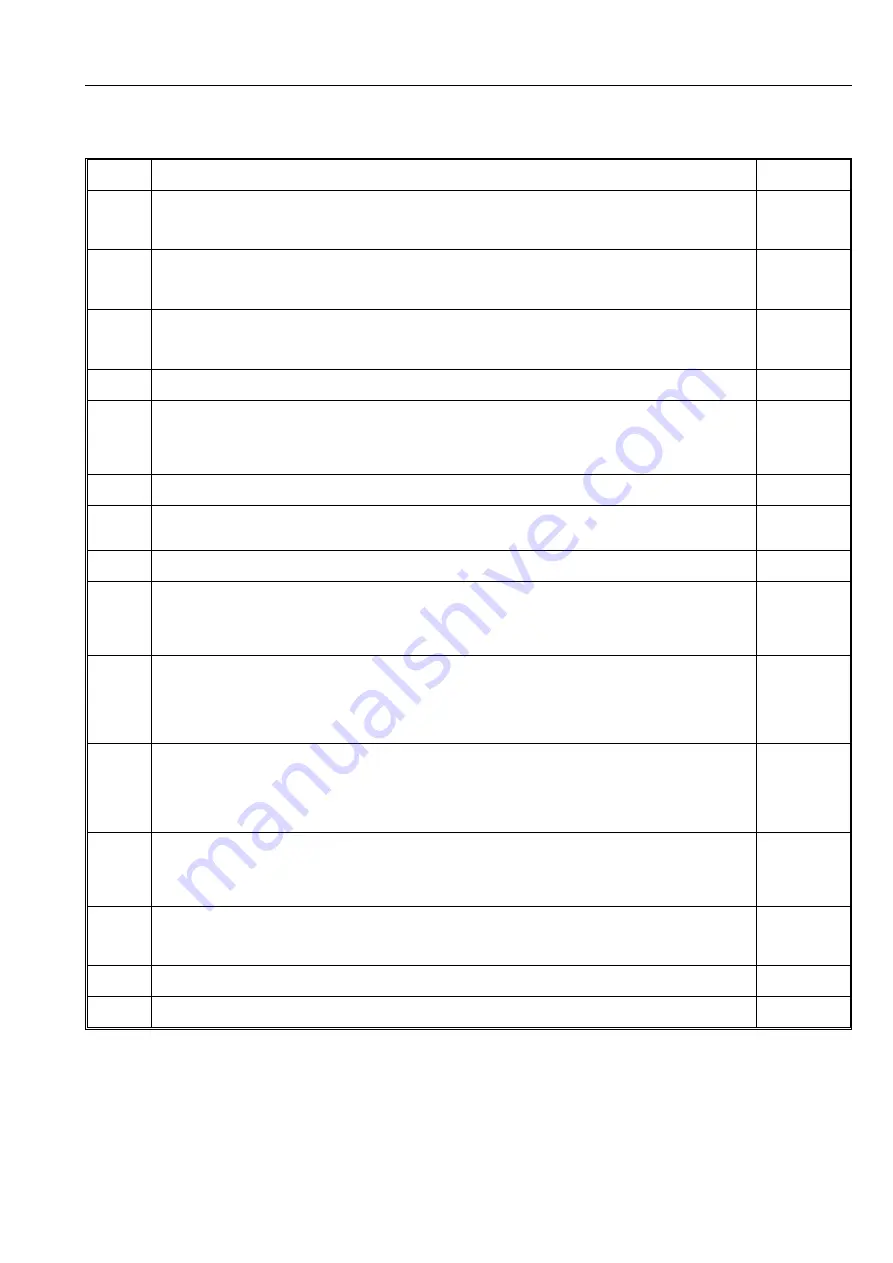

Adr.

Description

Works setting

010

Sampling: 6 programmes are in memory. One out of six can be selected in this address.

This programme will become active in automatic operating mode (after AUT has been operated).

Display and storage of selection time.

1

-

011

Condition: A protocol printer type Primo-Bit is connected.

No: No printout

Yes: The most important sampler operating data is printed out. Thereafter the display returns to No.

no

020

Number off and length of time of power failures - during automatic operation.

(The counters are reset on new automatic operation start.)

0000

-

021

Length of time of last power failure (reset on new automatic start).

-

022

Automatic operation stop using an external signal (the ext.-stop input must be

used and closed). All sample cycles are frozen whilst the signal is active

only date, time, cooling and heating continue to operate.

(The stop counter is reset on new automatic operation start)

0000

023

Length of time of last external stop signal (reset on new automatic operation start).

-

024

The positive edge of the signal at the "control input" (event or programme change)

increase the counter by one (The counter is reset on new automatic operation start)

0000

025

Length of time of last event or programme change.

-

030

Sample counter during automatic operation (counter value minus "no flow" value, address 032,

gives the actual number of samples taken)

(This counter is reset on new automatic operation start)

0000

031

This counter is increased by one and the time noted if a sample start occurs during an already

active sample cycle or when the overfill security is active. This sample is not taken..

Reasons: Time interval selection was too short. Flow quantity selection was too small. Overfill security active. or

very fast event sequences.

(This counter is reset on new automatic operation start)

0000

-

032

This counter is increased by one and the time noted if the dosing chamber is not totally filled

during the sample suction time. A fault message appears in the display, this message is deleted

at the start of the next sample cycle.

Reasons: Sampling point dry. Hose blocked or not properly sealed. Or suction time selection too short.

(This counter is reset on new automatic operation start)

0000

-

033

Data in addresses 030 to 032 set as single line information per bottle /container:

Bottle/container number, number of samples, number of sample starts, how often a no flow was recorded

Individual bottle data can be selected by operating ENTER until the bottle data required is in the display.

This is valid for all forms of distribution, eg. 1 to 12 bottles.

XX

0000

0000

0000

040

Condition: That the flow measurement analogue silgnal is connected to the "analogue input"

of the sampler.

xxxx m

3

/h

041

Target and actual temperature in the sample bottle surroundings. Display whether heating or cooling is active..

xx°C

042

Voltage measured at the 12 VDC input (Only valid for samplers operating with 12 volt direct current supply.

xx,x V

asp-station d 2

Operation and display

25