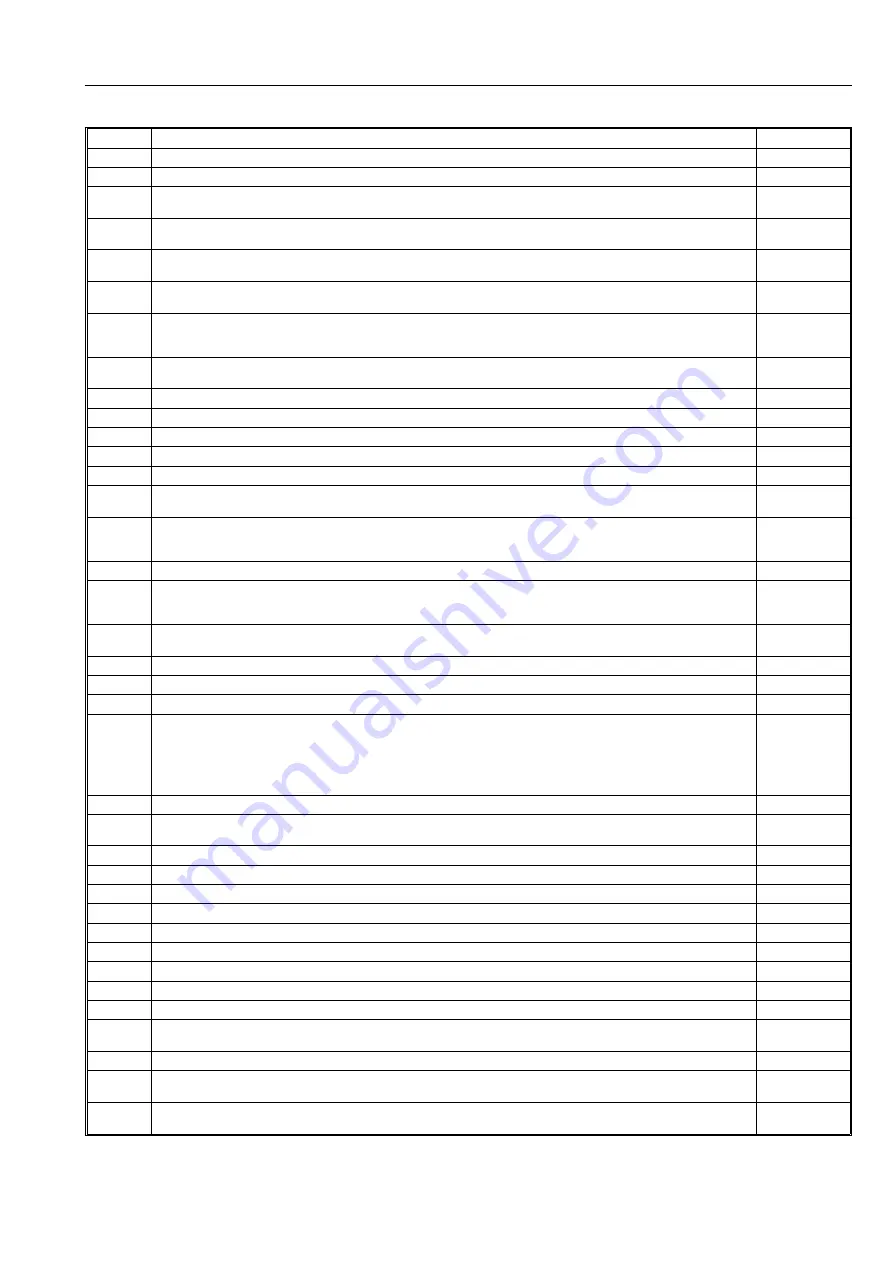

Addr.

Description

Works settings

110

Set up the same dosing volume as on the filling tube in the dosing chamber

300 ml

111

Set up single bottle / container volume (-10% for safety) (Addr. 110/111 operate as bottle overfill security).

00,6 l

120

The total sample time is dependent on the hose length suction height and liquid.

ON= self optimising. OFF= set up by user (Addr.121...123).

ON

121

The three phase times can be timed by taking manual samples (MAN push button).

Blow out time = time from pushing Man button until air bubbles come out of the hose at the sampling point.

-

122

Suction time = Time from when bubbles no longer appear at the sampling point

until the dosing chamber is filled.

-

123

Dosing time = Time after dosing chamber is filled until the liquid has reached its

preset dosing volume (bottom of filling tube).

-

124

Target time XXX seconds by which each sample is to be delayed.

Function: Sampling signal (output, see addr.150/151/152) is active XXX seconds

before sample start and remains until sample has been dosed.

000 Sec.

125

Conductivity switch setting; can be set to suit the liquid being sampled. Should only be used under special conditions, normal

operation set to middle.

middle

126

Time synchronised sampling

AUT button

127

Synchronisation time to which the sample cycles operate

00:00

128

Fixed allocation of bottle / container change selection (ON / OFF)

OFF

130

Activate or switch off cooling and heating automatic cycle.

ON

131

Set required sample preservation compartment temperature.

5 °C

132

Automatic refrigeration and heating phase (hourly defrost until internal temperature has increased by 2°C or a max 10 min.) or

manual settings

Yes

133

Defrost time

= Time in which the refrigeration fins are heated

Cycle

= Refrigeration running time until next defrost phase.

Input only accepted when cycle > time.

10

60

140

For quantity proportional sampling. Selection is dependent on the transmitter.

analogue

141

For analogue input. Selection is dependent on the transmitter output.

4..20mA has cable open circuit monitoring (fault display and message).

Note: Change switch in unit when using 0..1/10 V (see section "Change analogue input).

0...20 mA

142

For analogue input. Value and range is dependent on transmitter and flow rate.

Setting: Maximum flowrate, eg. 20 mA = 1000 m

3

/h

1000 m

3

/h

143

For analogue input. Set decimal point for the above value.

None

144

For impulse input. Set up litre or m

3

per impulse (dependent on transmitter).

-

145

For impulse input. Set decimal point for the above value.

-

150

Relay output 1 selection:

☛

Signal during container change (Distribution tap running)

☛

Signal during sampling

(see Addr. 124)

☛

Acknowledgement of external stop input

☛

Automatic sequence end (last bottle/container is full). Signal active until next automatic start sequence.

☛

Error signal "No flow". Signal active until next sample cycle.

☛

Error signal "Electrodes 1/" (conductivity electrodes) dirty. Signal active until (cleaned) acknowledged.

☛

All error signals and faults = cumulative alarm.

☛

Not used.

Probe 1/2

Soiled

151

Relay output 2 selection as above (Addr. 150)

Sample

152

Relay output 3, mains power connected. Selection as above (Addr. 150).

Switch function selectable as "Standard" or "Inverse".

Cumulat. alarm

"Standard"

160

Used for sample report printout using the serial printer type Primo-Bit.

Primo-Bit

161

Complete sample sequence report on paper (Primo-Bit), ON or OFF.

ON

162

Parameter report printed out on each automatic sample sequence start, ON or OFF

ON

163

For identification - Must be individually set up.

Liqui-box

164

Set up varying identifier addresses if multiple samples are connected in a TTY series link. Only available as an OPTION.

01

165

Set up TTY for Primo-Bit TTY (V24 =Option).

TTY

166

Set up 300 for Primo-Bit.

300 Baud

167

Set up "even" for Primo-Bit.

Parity even

168

Set up 1 for Primo-Bit.

1 Stop bit

169

Set up 7 for Primo-Bit.

Set up the following at the Primo-Bit: Code 6051, A1, Mod 010, B42, Code 9999.

7 Data bit

-

170/171

Change date / time.

actual

172

Automatic = Repeated yearly: Last Sunday in March at 2 o’clock: advance to 3 o’clock.

Last Sunday in September at 3 o’clock: reverse to 2 o’clock. (Off = no changeover)

Automatic

173/174

Manual (Addr.172): Set up advance and reverse switch times individually.

Note: Same values as in addr.173/174 stops changeover.

-

asp-station d 2

Operation and display

27