Cleanfit CUA451

Installation

Hauser

17

5.2

Mounting the assembly

L

WARNING

Medium flows out.

Risk of injury

‣

Only install the assembly when the process is deactivated.

‣

Before disassembling, always ensure that the process pipe and vessel are

unpressurized, empty and rinsed.

‣

Move the assembly to the service position.

‣

Close the ball valve.

5.2.1

Installing the assembly in the process

1. Mount the hand lever on the assembly.

2. Open the ball valve.

3. Move the assembly to the service position.

Retraction pipe is in the assembly.

4. Secure the assembly to the vessel or pipe using the selected process connection.

Flange process connection:

‣

Prior to installation, check the flange seal between the flanges.

G2 process connection

‣

Use a commercially available sealant (e.g. LOCTITE 561) to seal the G2 process

connection.

5.2.2

Rinse water connection (optional)

NOTICE

Water pressure too high

The assembly can be damaged.

‣

A pressure-reducing valve must be connected in series upstream if the water pressure

can increase to over 6 bar (87 psi).

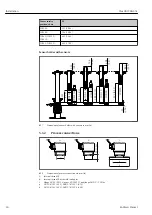

Rinse the sensor in the service position with a second ball valve for the rinse chamber (see

accessories).

1. Connect the rinse water line to the rinsing nozzle provided. The two rinse nozzles on

the assembly are identical and can be used in the inlet and outlet.

2. Operate the rinse water connection of the assembly with a water pressure of 2 bar to

max. 6 bar (29 to 87 psi).

3. Also install a check valve and a dirt trap (100 μm, see "Accessories") in the water pipe

(at the inlet to the assembly).

Apart from water, you can also pass other or additional cleaning solutions through

the rinse chamber. When doing so, pay attention to the material resistance of the

assembly and make sure to comply with the maximum permitted temperatures and

pressures.

5.2.3

Sensor installation

L

CAUTION

High pressure in the rinse chamber

Risk of injury from medium and pressure.

‣

Connect a hose to the vent valve and vent the rinse chamber carefully.