Cleanfit CUA451

Installation

Hauser

19

7.

1

1

A0038433

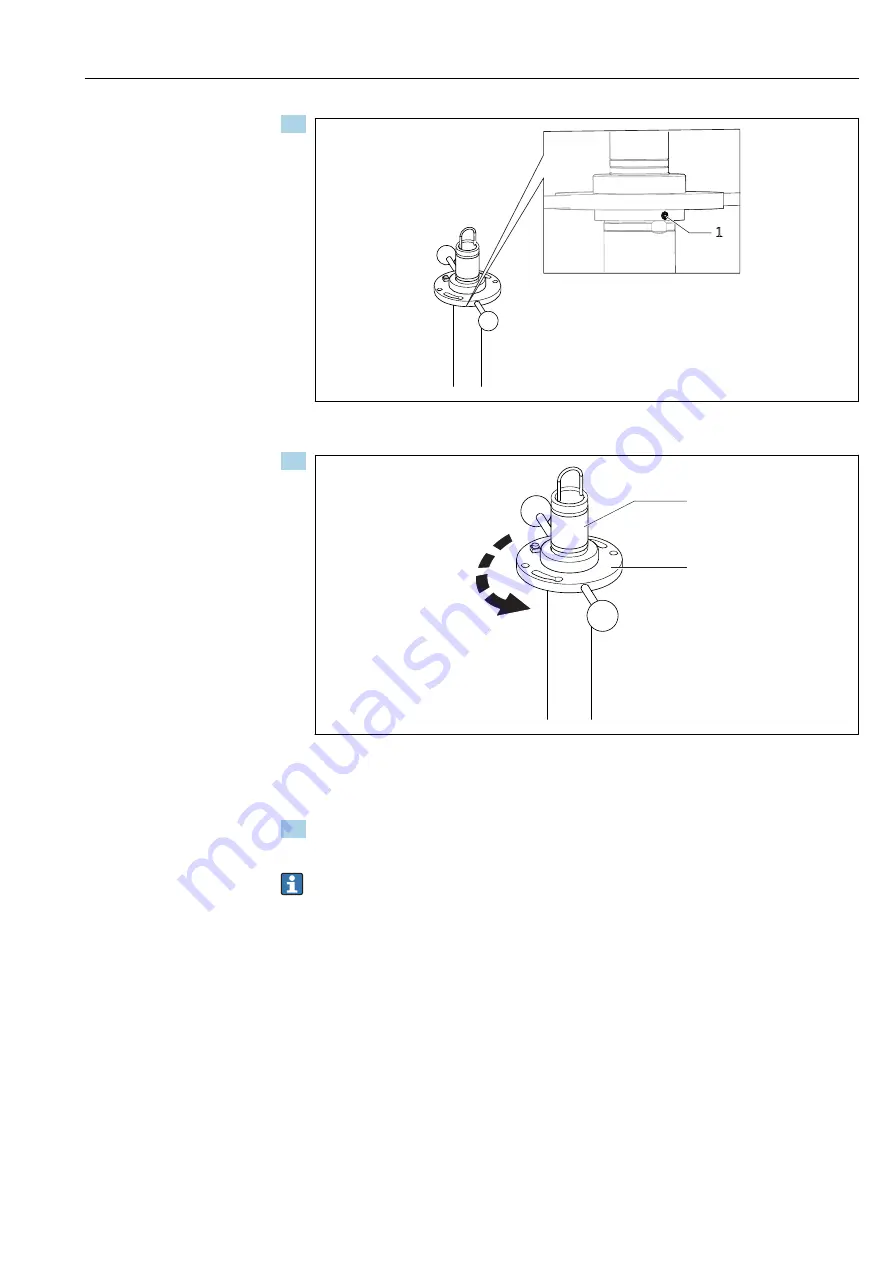

Release the grub screw (item 1) on the underside of the bayonet nut.

8.

1

2

A0038434

Unscrew the bayonet nut and the sensor holder (item 1) from the retraction pipe. In

doing so, hold the retraction pipe steady and turn the handles (2) counterclockwise

(approx. 9 turns).

9. Holding the handles, pull the bayonet nut, along with the sensor holder, out of the

retraction pipe.

When the sensor is installed, the bracket is the only possible way to check the

alignment of the sensor in the process! Observe the instructions on sensor alignment

in the Operating Instructions for the sensor.