Flowmeter Proline 500

Electrical connection

Hauser

17

5

Electrical connection

L

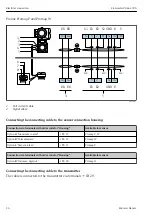

WARNING

Live parts! Incorrect work performed on the electrical connections can result in an

electric shock.

‣

Set up a disconnecting device (switch or power-circuit breaker) to easily disconnect the

device from the supply voltage.

‣

In addition to the device fuse, include an overcurrent protection unit with max. 10 A in the

plant installation.

5.1

Electrical safety

In accordance with applicable national regulations.

5.2

Connecting requirements

5.2.1

Required tools

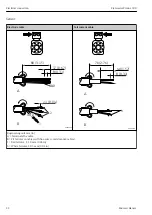

• For cable entries: Use corresponding tools

• For securing clamp: Allen key 3 mm

• Wire stripper

• When using stranded cables: crimper for wire end ferrule

• For removing cables from terminal: Flat blade screwdriver ≤ 3 mm (0.12 in)

5.2.2

Requirements for connecting cable

The connecting cables provided by the customer must fulfill the following requirements.

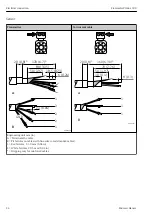

Protective grounding cable for the outer ground terminal

Conductor cross-section < 2.1 mm

2

(14 AWG)

The use of a cable lug enables the connection of larger cross-sections.

The grounding impedance must be less than 2 Ω.

Permitted temperature range

• The installation guidelines that apply in the country of installation must be observed.

• The cables must be suitable for the minimum and maximum temperatures to be expected.

Power supply cable (incl. conductor for the inner ground terminal)

Standard installation cable is sufficient.

Cable diameter

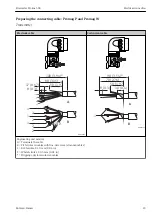

• Cable glands supplied:

M20 × 1.5 with cable ⌀ 6 to 12 mm (0.24 to 0.47 in)

• Spring-loaded terminals: Suitable for strands and strands with ferrules.

Conductor cross-section 0.2 to 2.5 mm

2

(24 to 12 AWG).

Summary of Contents for Flowmeter Proline 500

Page 47: ......