Proline Promass 500

Use in protective systems

Hauser

35

2. Compare current at output 1 with this default value.

Comparing the current values

The current values can be compared using one of the following methods:

• Measure the current of the DUT at the logic subsystem (process control system or safety-

related PLC).

• Measure the current at the DUT using an external, traceably-calibrated ammeter.

‣

Compare the current values.

Connecting the measuring equipment and external testing

• Connecting the measuring equipment in the measuring circuit

• External check of the passive current output

Requirements for the measuring equipment:

• DC current measuring uncertainty ±0.2 %

• DC current resolution10 µA

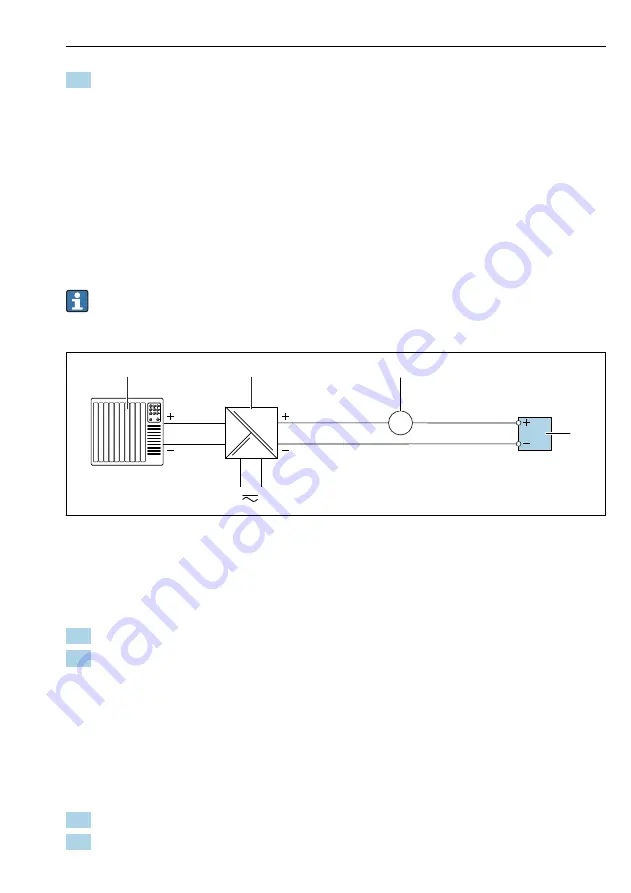

2

1

A

3

4

A0034446

5

External verification taking the example of a passive current output

1

Automation system with current input (e.. g. PLC)

2

Power supply unit

3

Ammeter

4

Transmitter

1. Connect the ammeter to the transmitter by looping it in series into the circuit.

2. Connect the power supply unit.

Evaluation of results - Part 2: Testing of current output 1

The amount of deviation between the measured current and the set point must not exceed the

measured error specified for the safety function. The deviation should not exceed ±1 % /

±300 µA.

‣

Note data relating to measured error→ 18.

Connecting the test

1. Re-activate the locked SIL mode→ 21.

2. Deactivate bypassing of safety function of process control system.

Summary of Contents for HART Proline Promass 500

Page 2: ......

Page 8: ...Certificate Proline Promass 500 8 Endress Hauser 2 Certificate A0033748 ...

Page 50: ......

Page 51: ......

Page 52: ...www addresses endress com ...