Micropilot M FMR244 with FOUNDATION Fieldbus

Mounting

Hauser

19

3.4.3

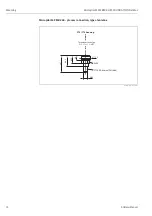

Installation in stilling well

Optimum mounting position

L00-FMR244xx-17-00-00-en-004

Standard installation

For installations in a stilling well, follow the engineering hints on Page 13 and note the following

points:

• Marker is aligned toward slots.

• Install the device using the threaded boss (AF 60) only. Observe the max. torque of 20 Nm.

• After mounting, the housing can be turned 350° in order to simplify access to the display and the

terminal compartment.

• Measurements can be performed through an open full bore ball valve without any problems.

Recommendations for the stilling well

At the construction of a stilling well, please note the following points:

• Metal (no enamel coating, plastic coating on request).

• Constant diameter.

• Stilling well diameter not larger than antenna diameter.

• Weld seam as smooth as possible and on the same axis as the slots.

• Slots offset 180° (not 90°).

• Slot width respectively diameter of holes max. 1/10 of pipe diameter, de-burred. Length and

number do not have any influence on the measurement.

• At any transition (i.e. when using a ball valve or mending pipe segments), no gap may be created

exceeding 1 mm.

• The stilling well must be smooth on the inside (average roughness Rz

≤

6.3

µ

m). Use extruded

or parallel welded stainless steel pipe. An extension of the pipe is possible with welded flanges or

pipe sleeves. Flange and pipe have to be properly aligned at the inside.

• Do not weld through the pipe wall. The inside of the stilling well must remain smooth. In case of

unintentional welding through the pipe, the weld seam and any unevenness on the inside need

to be carefully removed and smoothened. Otherwise, strong interference echoes will be generated

and material build-up will be promoted.

90°

90°

60

mark at threaded boss

G 1½”

or

1½ NPT

AF 60

max. torque

20 Nm

Caution!

Use only the

threaded boss