Proline Promass 83 FOUNDATION Fieldbus

6 Commissioning

Hauser

47

5.

Identify the field device using the DEVICE_ID that you noted down and assign the desired field

device tag name (PD_TAG) to the fieldbus device in question.

Factory setting: E+H_PROMASS_83_xxxxxxxxxxx

F06-83xFFxxx-20-xx-xx-xx-000

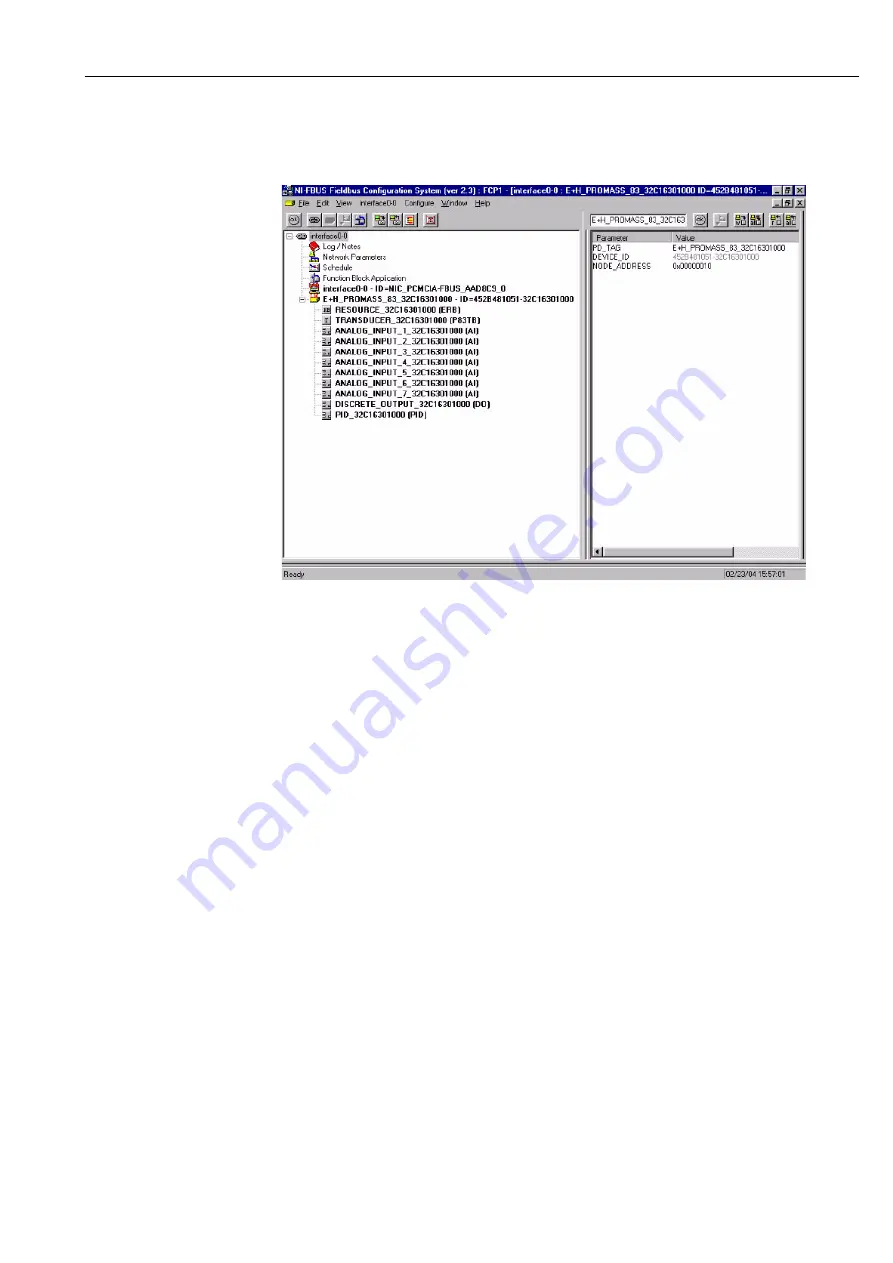

Fig. 28:

Screen display in the configuration program “NI-FBUS Configurator” (National Instruments) after connecting

Configuration of the “Resource Block”

6.

Open the Resource Block.

7.

On delivery write protection is disabled so that you can access all the write parameters. Check

this status via the parameter WRITE_LOCK:

– Write protection activated = LOCKED

– Write protection deactivated = NOT LOCKED

Deactivate the write protection if necessary

→

8.

Enter the desired block name (optional).

Factory setting: RESOURCE_ xxxxxxxxxxx

9.

Set the operating mode in the parameter group MODE_BLK (parameter TARGET) to AUTO.

Configuration of the “Transducer Block”

10. Enter the desired block name (optional).

Factory setting: TRANSDUCER_ xxxxxxxxxxx

11. Open the Transducer Block.

Summary of Contents for Proline Promass 83

Page 24: ...3 Installation Proline Promass 83 FOUNDATION Fieldbus 24 Endress Hauser ...

Page 34: ...4 Wiring Proline Promass 83 FOUNDATION Fieldbus 34 Endress Hauser ...

Page 64: ...6 Commissioning Proline Promass 83 FOUNDATION Fieldbus 64 Endress Hauser ...

Page 66: ...7 Maintenance Proline Promass 83 FOUNDATION Fieldbus 66 Endress Hauser ...

Page 90: ...9 Trouble shooting Proline Promass 83 FOUNDATION Fieldbus 90 Endress Hauser ...

Page 116: ...Index Proline Promass 83 FOUNDATION Fieldbus 116 Endress Hauser ...

Page 118: ...www endress com worldwide BA065D 06 en 12 04 50098623 FM SGML 6 0 ...